Titanium Alloy Products - Ti6Al4V & Titanium Grades Supplier

Aashish Metals stands as a leading manufacturer and supplier of high-performance, specializing in commercially pure titanium grades and the industry-standard Ti6Al4V alloy. Our comprehensive range of titanium fasteners, tube fittings, manifold valves, instrumentation ball valves, and pipes & tubes are manufactured to ASTM, ASME, and API specifications, ensuring superior reliability in the most demanding industrial applications.

Aashish Metals is a company that manufactures and supplies high-performance titanium alloy products, namely commercially pure grades of titanium and industry standard grade of Ti6Al4V. All our titanium fasteners, tube fittings, manifold valves, instrumentation ball valves, and pipes and tubes are produced in accordance with the ASTM, ASME and API standards which guarantee high reliability to meet the most challenging requirements of the industry.

Having decades of experience in titanium alloy metallurgy and precise manufacturing, we offer solutions that can provide the highest strength to weight ratios, remarkable corrosion resistance, and longer service life of the industry, where failure is not a choice.

Titanium Grades - Complete Material Specifications

The metallurgical characteristics of various grades of titanium are important in the selection of the material. Our main product range includes Grade 2 commercially pure titanium, Ti6Al4V (Grade 5), and Ti 6Al 4V ELI that are used in special medical and cryogenic applications.

Chemical Composition & Mechanical Properties

| Property | Grade 2 (CP Titanium) | Ti6Al4V (Grade 5) | Ti 6Al 4V ELI (Grade 23) |

|---|---|---|---|

| Common Designations | Commercially Pure Ti, CP Ti | Ti6Al4V, 6Al 4V, Ti64 titanium | Ti 6Al 4V ELI, Medical Grade |

| Aluminum Content | – | 5.5−6.75% | 5.5−6.5% |

| Vanadium Content | – | 3.5−4.5% | 3.5−4.5% |

| Oxygen (max) | 0.25% | 0.20% | 0.13% |

| Tensile Strength | 345 MPa (50 ksi) min | 895−930 MPa (130-135 ksi) | 860 MPa (125 ksi) min |

| Yield Strength | 275 MPa (40 ksi) min | 828 MPa (120 ksi) min | 795 MPa (115 ksi) min |

| Key Advantage | Maximum corrosion resistance | High strength-to-weight ratio | Enhanced fracture toughness |

| Primary Applications | Chemical processing, marine | Aerospace, high-pressure systems | Medical implants, cryogenic |

Comprehensive Titanium Alloy Product Range

Fasteners

Our precision-manufactured titanium alloy fasteners deliver reliable mechanical joining solutions, with Ti64 titanium fasteners providing maximum strength for critical aerospace and structural applications.

- Titanium Gr.2 Fasteners : Hex bolts, socket screws, nuts, washers, studs | M3-M48 | Grade 2: 275 MPa yield strength | Maximum corrosion resistance

- Titanium Gr.5 Fasteners : High-strength hex bolts, cap screws, nuts | M3-M48 | Ti6Al4V: 828 MPa yield strength | Aerospace-grade strength

| Product | Grades Available | Size Range | Applications |

|---|---|---|---|

| Titanium Gr 2 Fasteners | Grade 2 CP Titanium | M3-M48, 1/8″-2″ | Chemical processing, marine, food processing |

| Titanium Gr 5 Fasteners | Ti6Al4V (Grade 5) | M3-M48, 1/8″-2″ | Aerospace, high-pressure systems, structural |

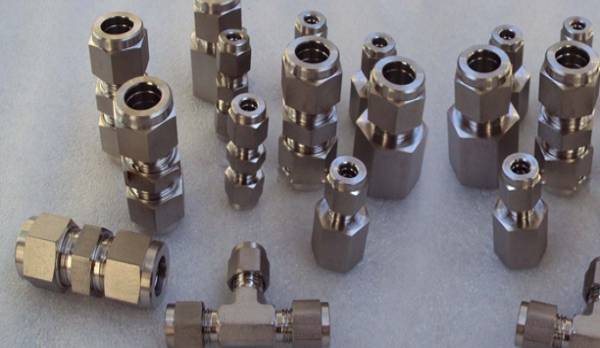

Tube Fittings

Our instrumentation-grade titanium alloy tube fittings ensure leak-free connections in critical measurement systems, with Ti6Al4V fittings providing enhanced pressure ratings.

- Titanium Gr 2 Instrumentation Tube Fittings : Compression fittings, unions, elbows, tees | Up to 6,000 psi | Chemical processing applications

- Titanium Gr 5 Instrumentation Tube Fittings: High-pressure fittings, connectors | Up to 10,000 psi | Aerospace & high-pressure systems

| Product | Grades Available | Configuration Types | Pressure Rating |

|---|---|---|---|

| Titanium Gr 2 Tube Fittings | Grade 2 CP Titanium | Unions, elbows, tees, cross, male/female connectors | Up to 6,000 psi |

| Titanium Gr 5 Tube Fittings | Ti6Al4V (Grade 5) | Unions, elbows, tees, cross, male/female connectors | Up to 10,000 psi |

Manifold Valves

High-precision manifold valves engineered for critical instrumentation and pressure measurement applications in harsh environments.

- Titanium Gr 2 Manifold Valves : 2-valve, 3-valve, 5-valve configurations | Max 6,000 psi | Chemical & marine applications

- Titanium Gr 5 Manifold Valves : 2-valve, 3-valve, 5-valve configurations | Max 10,000 psi | Aerospace & high-pressure systems

| Product | Grades Available | Valve Configurations | Max Pressure |

|---|---|---|---|

| Titanium Gr 2 Manifold Valves | Grade 2 CP Titanium | 2-valve, 3-valve, 5-valve | 6,000 psi (414 bar) |

| Titanium Gr 5 Manifold Valves | Ti6Al4V (Grade 5) | 2-valve, 3-valve, 5-valve | 10,000 psi (689 bar) |

Instrumentation Ball Valves

Precision-engineered titanium ball valves offering superior shut-off capability and reliability in demanding process control applications.

- Titanium Gr 2 Instrumentation Ball Valves: 1-piece, 2-piece, 3-piece body | 1/4" to 2" | API 598, ASME B16.34 | Up to 6,000 psi

- Titanium Gr 5 Instrumentation Ball Valves: 1-piece, 2-piece, 3-piece body | 1/4" to 2" | API 598, ASME B16.34 | Up to 10,000 psi

| Product | Grades Available | Body Construction | Max Pressure |

|---|---|---|---|

| Titanium Gr 2 Ball Valves | Grade 2 CP Titanium | 1-piece, 2-piece, 3-piece | Up to 6,000 psi |

| Titanium Gr 5 Ball Valves | Ti6Al4V (Grade 5) | 1-piece, 2-piece, 3-piece | Up to 10,000 psi |

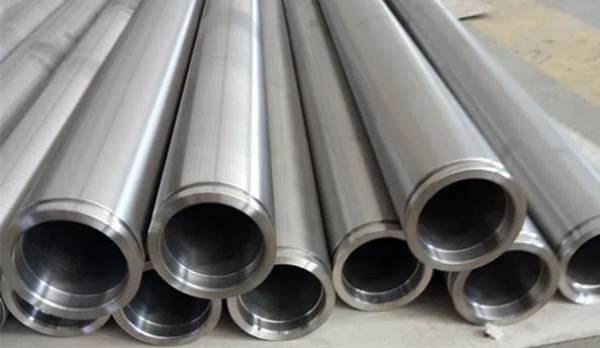

Pipes & Tubes

Comprehensive range of seamless and welded titanium pipes and tubes for diverse industrial applications requiring superior corrosion resistance.

- Titanium Gr 2 Pipes & Tubes: Seamless & welded | 6mm - 219mm OD | Heat exchangers, condensers, process piping

- Titanium Gr 5 Pipes & Tubes: Seamless & welded | 6mm - 219mm OD | Aerospace ducting, high-pressure hydraulics, power generation

| Product | Grades Available | Types Available | Key Applications |

|---|---|---|---|

| Titanium Gr 2 Pipes & Tubes | Grade 2 CP Titanium | Seamless tubes, welded pipes, heat exchanger tubes | Heat exchangers, condensers, chemical processing |

| Titanium Gr 5 Pipes & Tubes | Ti6Al4V (Grade 5) | Seamless tubes, welded pipes, instrumentation tubing | Aerospace, high-pressure hydraulics, power generation |

Standards Compliance: ASTM B338, B337, B861, B862, AMS specifications

Industry Applications for Titanium Grades

- Chemical & Petrochemical: Grade 2 titanium is most resistant to corrosion in chloride with Ti6Al4V being stronger than Grade 2 titanium in high-pressure reactor systems and valves in a corrosive environment.

- Aerospace & Defense: Ti6Al4V (Ti64) is widely applied in the aerospace industry to airframes, engine components and landing gear because of its superior strength to weight ratio and performance at high temperature (up to 400°C).

- Medical & Pharmaceutical: Ti 6Al 4V ELI is the best option of orthopedic implants, dental fixations, and surgical tools because the material is highly biocompatible and fracture-tough.

- Oil & Gas – Offshore: Titanium is used to guarantee long service of subsea wellheads and topside equipment. Grade 2 is used in the heat exchangers and Ti6Al4V offers high strength solutions in bolting of heat exchangers with a life span of 25 years or more.

Material Selection Guide for Titanium Grades

Select Grade 2 (CP Titanium) for:

- Maximum corrosion resistance in aggressive chemicals

- Excellent formability and weldability

- Seawater and marine applications

- Cost-sensitive projects requiring biocompatibility

Select Ti6Al4V (Grade 5) for:

- High-strength structural applications

- Aerospace components (up to 400°C)

- High-pressure systems (>6,000 psi)

- Severe cyclic loading and fatigue requirements

Select Ti 6Al 4V ELI for:

- Long-term implantable medical devices

- Cryogenic applications

- Critical aerospace components requiring ductility

Quality Assurance & Certifications

Aashish Metals maintains comprehensive quality management systems to ensure every titanium alloy product meets or exceeds specified requirements and international standards.

- Certifications: ISO 9001:2015, ISO 14001:2015, NACE MR0175 compliance.

- Documentation: Mill Test Certificates (EN 10204 3.1/3.2), Chemical analysis verification, Heat number traceability.

- Testing: Positive Material Identification (PMI), Ultrasonic and eddy current examination, Mechanical property testing.

Frequently Asked Questions

Ti 6Al 4V ELI (Extra Low Interstitial) contains lower oxygen (0.13% max vs 0.20% max), nitrogen, and iron content compared to standard Ti6Al4V. This results in approximately 15-20% higher ductility and significantly improved fracture toughness, making it preferred for medical implants and cryogenic applications.

Yes, Ti64 titanium (Ti6Al4V) exhibits excellent corrosion resistance in seawater. However, for maximum corrosion resistance in continuous seawater immersion, Grade 2 is typically preferred. Ti6Al4V is ideal when both high strength and corrosion resistance are required.

6Al 4V refers to the chemical composition containing approximately 6% Aluminum and 4% Vanadium, with the balance being titanium. This is the same material as Ti6Al4V, Ti 6Al 4V, or Ti64 titanium – all are different naming conventions for Grade 5 titanium alloy.

All our Ti6Al4V products include Mill Test Certificates with complete chemical analysis confirming the 6% Aluminum and 4% Vanadium content, mechanical property test results, and heat number traceability. We provide Positive Material Identification (PMI) testing using XRF analyzers to verify alloy composition.

For More Information About Titanium Alloy Product please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Materials

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- Thank You For Connecting

- Duplex and Super Duplex Steel Pipes and Tubes

- Duplex and Super Duplex Steel Threaded Fittings Manufacturer and Supplier

- Duplex Steel S31803 S32205 and Super Duplex S32750 S32760 Pipe Fittings

- Duplex S31803 S32205 Socket Weld Fittings Manufacturer

- Duplex and Super Duplex Steel Socket Weld Fittings

- Duplex and Super Duplex Steel Tube Fittings

- Stainless Steel 316 / 316L Pipes & Tubes

- Stainless Steel 321 Pipes & Tubes

- Inconel Pipes and Tubes

- Home uat

- Stainless Steel Pipe Fittings Manufacturer and Supplier

- Stainless Steel Pipes and Tubes

- C17200 Beryllium Copper

- C17300 Beryllium Copper

- C17500 Beryllium Copper

- BERYLLIUM COPPER STRIP & COIL

- Beryllium Copper C17200 Wire

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.