Duplex and Super Duplex Stainless Steel Products

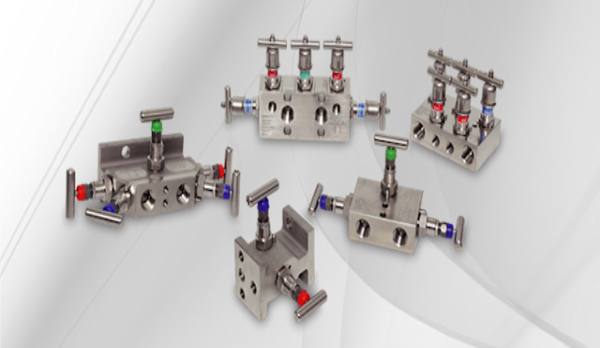

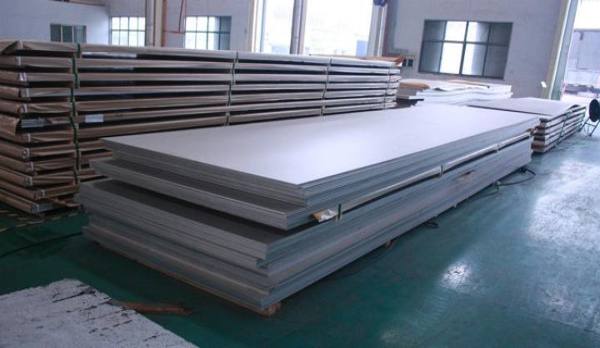

Duplex and Super Duplex stainless steel products are supplied for applications that require both high strength and remarkable corrosion resistance.We are a manufacturer and supplier of pipes, fittings, valves, fasteners, plates, sheets, and round bars used in offshore systems, marine systems, chemical systems, and industrial systems.

Product Category Range

Our stainless steel product range of Duplex and Super Duplex is so organized as to accommodate full material needs in pipe, flow control, fastening and fabrication needs. To provide the compatibility of the products, durability, and long-term performance, each of the product categories below is delivered in controlled material grades.

- Duplex and Super Duplex Stainless Steel Grades Overview

- Chemical Composition of Duplex and Super Duplex Stainless Steel

- Mechanical Properties of Duplex and Super Duplex Stainless Steel

- Equivalent Grades of Duplex and Super Duplex Stainless Steel

- Key Properties of Duplex and Super Duplex Stainless Steel

- Applications of Duplex and Super Duplex Stainless Steel Products

- Quality Control and Supply Capability

- FAQs About Duplex and Super Duplex Stainless Steel Products

Duplex and Super Duplex Stainless Steel Grades Overview

The procurement of duplex and super duplex stainless steel is influenced by the specific grades, heat treatments, and the precision of the documentation. Aashish Metal supports procurement and engineering teams by ensuring that all supplies align with the required material grade, form, and project specifications.

Super Duplex stainless steel grades such as UNS S32750 and UNS S32760 offer increased alloy content and consequently, increased resistance to pitting, crevice corrosion and erosion corrosion. These are materials that are chosen due to severe service conditions such as high chloride concentration, pressure and mechanical loading. Duplex 2205 and Super Duplex 2507 material requirements are maintained by us as a manufacturer and supplier in any form of product.

Chemical Composition of Duplex and Super Duplex Stainless Steel

| Element | Duplex Stainless Steel (%) | Super Duplex Stainless Steel (%) |

|---|---|---|

| Chromium (Cr) | 21.0 – 23.0 | 24.0 – 26.0 |

| Nickel (Ni) | 4.5 – 6.5 | 6.0 – 8.0 |

| Molybdenum (Mo) | 2.5 – 3.5 | 3.0 – 4.0 |

| Nitrogen (N) | 0.14 – 0.20 | 0.24 – 0.32 |

| Carbon (C) | ≤ 0.03 | ≤ 0.03 |

| Manganese (Mn) | ≤ 2.00 | ≤ 1.20 |

| Silicon (Si) | ≤ 1.00 | ≤ 0.80 |

| Phosphorus (P) | ≤ 0.03 | ≤ 0.035 |

| Sulfur (S) | ≤ 0.02 | ≤ 0.01 |

Mechanical Properties of Duplex and Super Duplex Stainless Steel

| Property | Duplex Stainless Steel | Super Duplex Stainless Steel |

|---|---|---|

| Yield Strength (MPa) | ≥ 450 | ≥ 550 |

| Tensile Strength (MPa) | 620 – 880 | 750 – 950 |

| Elongation (%) | ≥ 25 | ≥ 15 |

| Hardness (HB max) | ≤ 290 | ≤ 310 |

| Impact Toughness | Good | Moderate to Good |

Equivalent Grades of Duplex and Super Duplex Stainless Steel

| Material Type | UNS | EN | DIN | ASTM / ASME |

|---|---|---|---|---|

| Duplex 2205 | S32205 / S31803 | 1 | X2CrNiMoN22-5-3 | ASTM A240 / A790 |

| Super Duplex 2507 | S32750 | 1 | X2CrNiMoN25-7-4 | ASTM A240 / A790 |

| Super Duplex (Enhanced) | S32760 | 1 | — | ASTM A240 |

Key Properties of Duplex and Super Duplex Stainless Steel

Duplex and Super Duplex stainless steel materials are engineered to deliver a balanced combination of mechanical strength and corrosion resistance. Compared to conventional stainless steel, these alloys offer higher yield strength, improved resistance to stress corrosion cracking, and reliable performance in chloride-rich environments.

The dual-phase microstructure contributes to dimensional stability, reduced material thickness requirements, and extended service life. These properties make Duplex and Super Duplex steel suitable for pressure-bearing components, marine exposure, and chemically aggressive operating conditions where long-term reliability is critical.

Applications of Duplex and Super Duplex Stainless Steel Products

Duplex and Super Duplex stainless steel products find applications in the various industry sectors where high levels of corrosion resistance and mechanical integrity of the products are necessary in harsh conditions. Common systems of use are offshore oil and gas systems, marine piping networks, chemical and petrochemical processing units, desalination plants, heat exchangers, pressure vessels and high pressure fluid handling systems.

The choice of different product forms that include pipes, fittings, valves, fasteners, plates and bars is based on the fabrication, pressure rating and exposure to the environment. This is helped by the use of the same grade of Duplex or Super Duplex material in these components to ensure system reliability and continuity of corrosion resistance.

Quality Control and Supply Capability

The supply of Duplex and Super Duplex stainless steel products must be closely controlled in terms of material chemistry, mechanical properties and documentation. Being a manufacturer and supplier, we assist procurement and engineering teams with grade checks, standards compliance, and full material traceability.

Certificates and inspection documents are provided on products supplied as demanded, to support domestic and export project requirements. We are able to supply several types of products enabling us to coordinate sourcing in projects that would demand Duplex and Super Duplex products in piping and structural items.

Related Alloy Product Categories

The following alloy product categories are commonly sourced alongside Duplex and Super Duplex stainless steel products for projects involving corrosion resistance, high strength, and demanding service conditions:

Why Choose Aashish Metal for Duplex and Super Duplex Stainless Steel Products

Duplex and Super Duplex stainless steel production is sensitive to grade selection, heat treatment and accuracy in documentation. Aashish Metal facilitates procurement and engineering departments by matching all supplies to the material grade, form and project specification needed.

We supply products made from Duplex steel and Super Duplex stainless steel, including pipes and tubes, fittings, valves, fasteners, plates, sheets and round bars with material traceability and documentation provisions. Every order is addressed with definite technical validation to minimise discrepancy at order stage. In projects where uniformity in content is needed across many of the parts, our line of products can be used to consolidate the purchasing process and ensure that the grades of the entire system are compatible.

In case of export and project supply we assist in packaging and dispatch needs depending on the nature of products and conditions of movement. This strategy is used to allow buyers to handle compliance, lower sourcing risk, and quality consistency via procurement and execution.

FAQs About Duplex and Super Duplex Stainless Steel Products

Duplex steel is a stainless steel with higher strength and improved resistance to chloride stress corrosion cracking. It is commonly used in piping, fittings, and fasteners for chemical, marine, and industrial applications.

Super Duplex stainless steel offers higher resistance to pitting and crevice corrosion compared to Duplex 2205, making it suitable for offshore, seawater, and high chloride environments.

Common Duplex grades include UNS S31803 and UNS S32205, while Super Duplex grades include UNS S32750 and UNS S32760. Grade selection depends on corrosion risk and service conditions.

Yes. Duplex and Super Duplex stainless steel products are supplied in pipes and tubes, pipe fittings, threaded fittings, socket weld fittings, tube fittings, valves, fasteners, plates, sheets, and round bars.

Mill test certificates and traceability details are typically provided. Additional inspection or documentation can be supported based on project and customer requirements.

Yes. These alloys are widely used in offshore and marine systems due to strong resistance to seawater corrosion and chloride-driven damage.

Duplex 2205 is often selected for moderately aggressive chloride environments. Super Duplex 2507 is chosen when higher corrosion resistance and strength are required in severe seawater or offshore conditions.

For More Information About Duplex and Super Duplex Stainless Steel Products please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Materials

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- Thank You For Connecting

- Duplex and Super Duplex Steel Pipes and Tubes

- Duplex and Super Duplex Steel Threaded Fittings Manufacturer and Supplier

- Duplex Steel S31803 S32205 and Super Duplex S32750 S32760 Pipe Fittings

- Duplex S31803 S32205 Socket Weld Fittings Manufacturer

- Duplex and Super Duplex Steel Socket Weld Fittings

- Duplex and Super Duplex Steel Tube Fittings

- Stainless Steel 316 / 316L Pipes & Tubes

- Stainless Steel 321 Pipes & Tubes

- Inconel Pipes and Tubes

- Home uat

- Stainless Steel Pipe Fittings Manufacturer and Supplier

- Stainless Steel Pipes and Tubes

- C17200 Beryllium Copper

- C17300 Beryllium Copper

- C17500 Beryllium Copper

- BERYLLIUM COPPER STRIP & COIL

- Beryllium Copper C17200 Wire

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.