Stainless Steel 310 310S Instrumentation Tube Fittings Supplier

Home › Stainless Steel › Stainless Steel 310 310S Tube Fittings

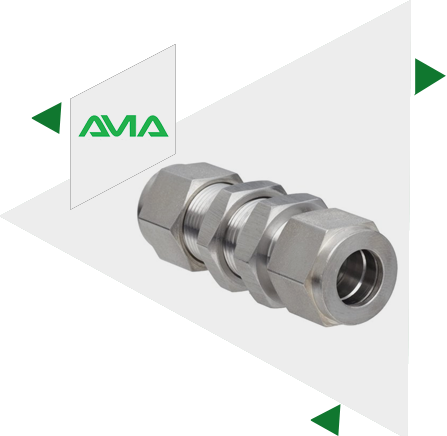

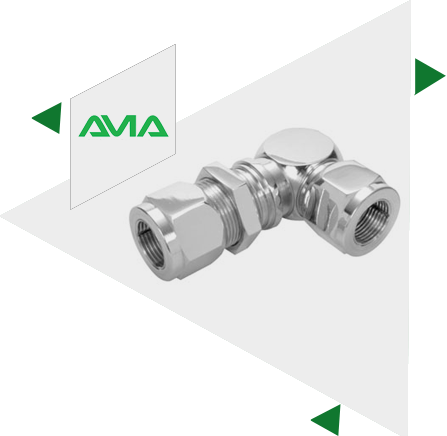

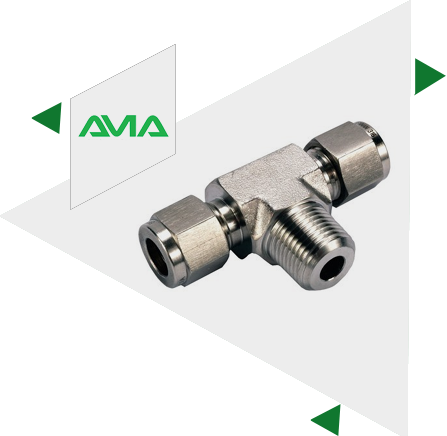

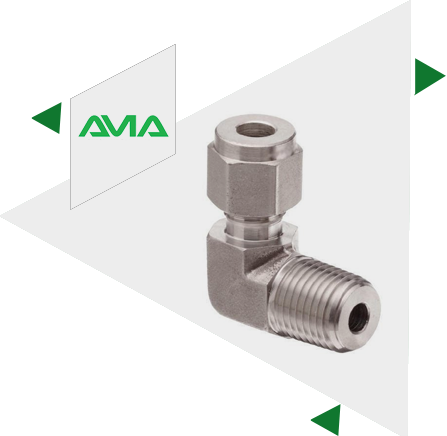

Aashish Metals company is a well-known company producing and selling Stainless steel 310 and 310S instrumentation tube fittings that have features of accuracy, steadiness and elevated temperatures of functioning. These fittings are designed to ASTM A479 and A276 and are manufactured of UNS S31000 and S31008 grade and have proven to be leak free, corrosion resistant and stable in oxidation and offering leak free sealing of the vital industrial systems. Ferrule, hydraulic and compression fitting are available, SS 310 tube fittings are used in the refineries, chemical plants, heat exchangers and at the power generation units. All products are MTC 3.1 certified and tested by third parties to be accurate in terms of dimensions and long service.

SS 310 310S Instrumentation Tube Fittings, Stainless Steel 310S Ferrule Fittings, SS 310 Hydraulic Instrumentation Fittings, ASTM A479 SS 310 Tube Fittings, ASTM A276 SS 310S Compression Fittings, UNS S31000 S31008 Instrumentation Fittings, WNR 1.4841 1.4845 Tube Fittings, SS 310 Instrumentation Tube Fittings Manufacturer and Supplier in India

We also offer various types of SS 310 and 310S instrumentation tube fittings such as ferrule fittings, compression fittings, hydraulic adapters as well as tube to union connectors. These fittings are formed as per ASTM A479 and ASTM A276 standards, are highly sealed, resistant to corrosion, and increase their life cycle in high-pressure and in high-temperature condition. They are produced in the finest grades (UNS S31000 / S31008 and WNR 1.4841 / 1.4845) to stabilize the performance and ensure the right dimensions. They are applied in the most favorable way to instrumentation lines, chemical plants, refineries, heat exchangers and power production systems to get leak-free and extended life.

Table of Content

- Technical Specifications of Stainless Steel 310 310S Tube Fittings as per ASTM A479 / A276

- Available Sizes and Grades of Stainless Steel 310 310S Instrumentation Tube Fittings

- Stainless Steel 310 310S Tube Fittings Price List

- Equivalent Grades of Stainless Steel 310 310S Instrumentation Tube Fittings as per ASTM A479 / A276

- Chemical Composition of Stainless Steel 310 310S Instrumentation Tube Fittings (UNS S31000 / S31008)

- Mechanical Properties of Stainless Steel 310 310S Instrumentation Tube Fittings Tensile Strength & Hardness

- Standard Dimensions of SS 310 310S Instrumentation Tube Fittings for Hydraulic and Compression Systems

- Related Products

- Applications of Stainless Steel 310 310S Instrumentation Tube Fittings in Industrial Systems

- Testing and Quality Inspection of Stainless Steel 310 310S Instrumentation Tube Fittings

Stainless Steel 310 310S Tube Fittings, SS 310S Ferrule and Compression Fittings, SS 310 Hydraulic and Instrumentation Tube Fittings, ASTM A479 SS 310 Tube Fittings, ASTM A276 SS 310S Tube Fittings, UNS S31000 S31008 Tube Fittings, WNR 1.4841 1.4845 Fittings, SS 310 310S Tube Fittings Suppliers and Exporters in India

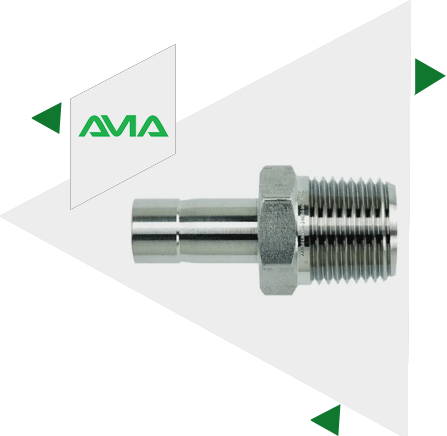

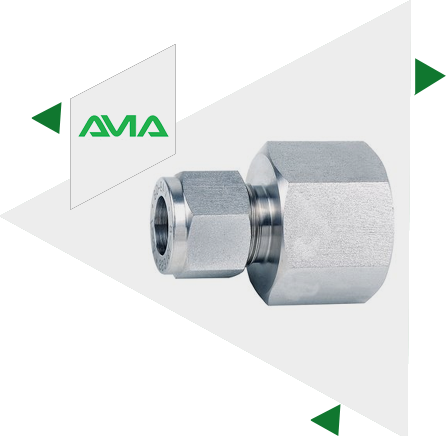

Stainless Steel 310 Instrumentation Tube Fittings

The Stainless Steel 310 Instrumentation Tube Fittings is developed to provide ideal performance in high pressure and high temperature systems in the majority of industrial systems. They are produced in compliance with ASTM A479 of UNS S31000 material and provide leak-free connections of both the hydraulic and the pneumatic lines that are reliable. They also outperform in oxidation and scaling resistivity and are applicable in the instrumentation, chemical and power generation departments. The fittings are mechanically robust in altering thermal conditions provide dimensional stability and also corrosion protection in refineries and heat exchangers and process control systems.

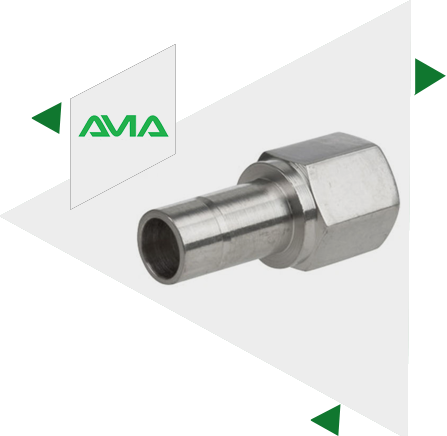

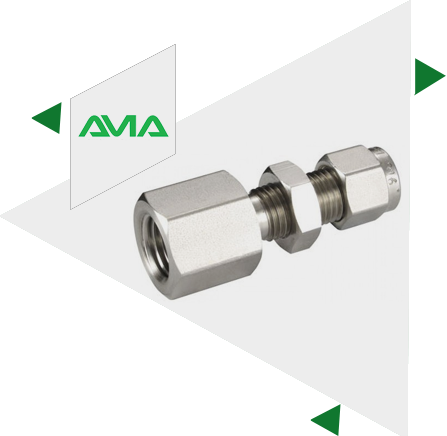

Stainless Steel 310S Instrumentation Tube Fittings

The stainless steel 310S Instrumentation Tube Fittings are a low-carbon type that is further improved by welding and also least exposed to sensitization on the extended heat exposure. They are manufactured as per ASTM A479 and UNS S31008 requirements and the alloys depict a very high degree of resistance against oxidation, creep and intergranular corrosion. These tube fittings apply in instrumentation, steam and condensate systems which are inert to leaks and require absolute precision when assembling. They are the most suitable parts to be used in chemical processing plants, in the sea and thermal equipment where performance and service life matter and they are high temperature strength parts with a smooth surface finish and high formability.

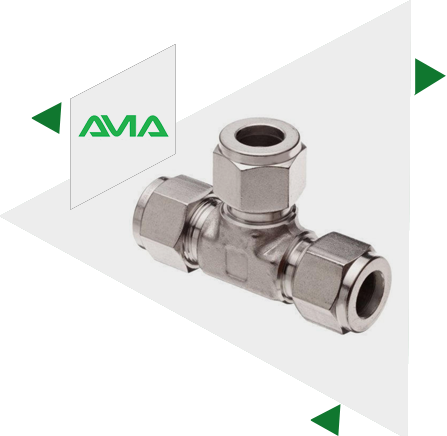

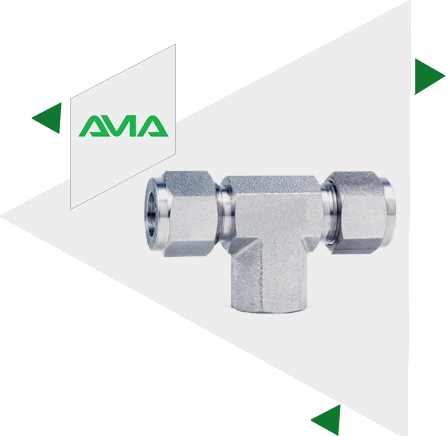

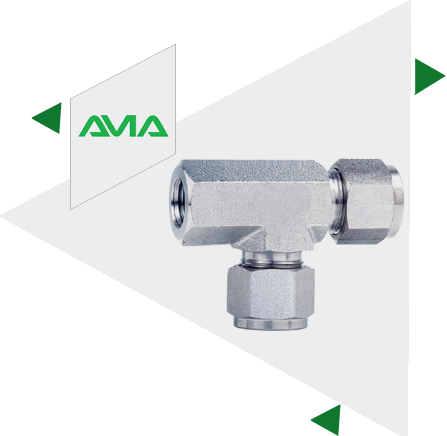

Stainless Steel 310 Ferrule Instrumentation Fittings

Its Stainless Steel 310 Ferrule Instrumentation Fittings have a two-ferrule design that is highly-engineered and offers the secure, vibration-free and leak-free tube connections. These fittings are produced with the help of WNR 1.4841 / 1.4845 grades and it can be used in chloride and sulfur-filled environment with great tensile strength and corrosion resistance. They operate under extreme pressure and temperature environment with high reliability and structural integrity throughout the gas distribution networks, the power plant itself as well as the control instruments systems. All the fittings comply with the MTC 3.1 and pass the test of tough dimensions and pressure to ensure that they conform to the international standards.

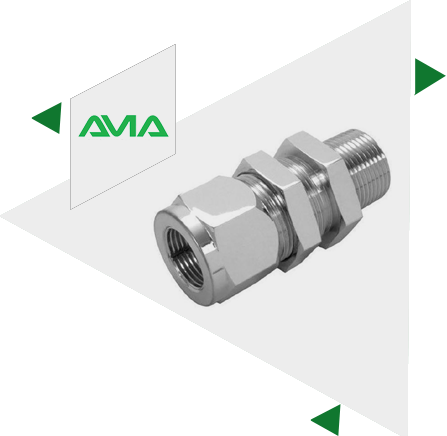

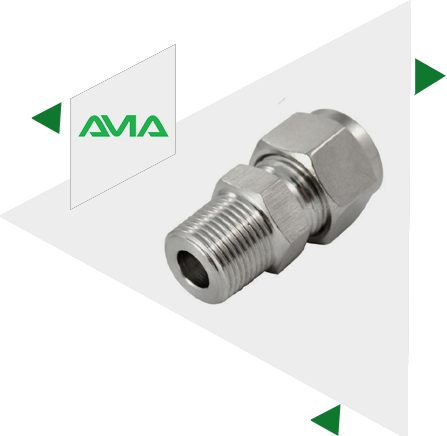

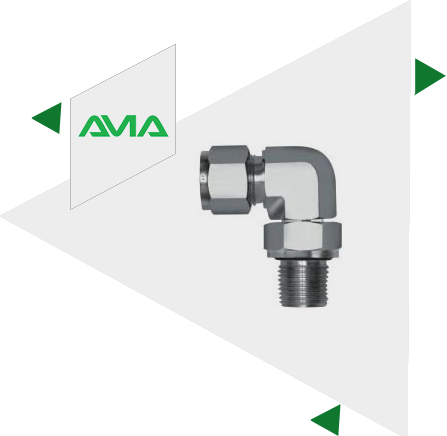

Stainless Steel 310 Hydraulic Instrumentation Fittings

The Stainless Steel 310 hydraulic instrumentation Fittings are designed to fit the exact hydraulic and fluid transfer systems which operate under the demanding industrial conditions. These fittings are fabricated as per ASTM A479 / UNS S31000 which is a blend of mechanical strength with excellent oxidation and creep resistance. They have high composition of chromium-nickel alloy that ensures high performance even under continuous pressure without leakage through sealing even when cycle of temperature fluctuation is taken. Broad areas of use SS 310 hydraulic fittings are widely used in refineries, heat-treatment plants and chemical process units with long service life, dimensional accuracy and stable high reliability in extreme service.

Technical Specifications of Stainless Steel 310 310S Tube Fittings as per ASTM A479 / A276

| Specification | Details |

|---|---|

| Material Grade | Stainless Steel 310 / 310S |

| Standards | ASTM A479 / A276 |

| UNS Number | S31000 (310), S31008 (310S) |

| WNR Number | 1.4841 (310), 1.4845 (310S) |

| Form | Tube Fittings – Ferrule, Hydraulic, Compression, Instrumentation |

| Manufacturing Process | Cold-formed or machined from seamless tube / bar stock |

| Type | Straight, Elbow, Tee, Reducer, Union, Adapter, Connector |

| Size Range | 1/8″ OD to 2″ OD (custom sizes available) |

| End Connections | NPT, BSP, Compression, Ferrule, Tube-to-Union |

| Thread Type | ISO / DIN / NPT (as per client specification) |

| Surface Finish | Bright Annealed / Polished / Pickled |

| Temperature Range | Up to 1150°C (2100°F) for continuous service |

| Pressure Rating | Up to 6000 PSI (depending on fitting type & size) |

| Certification | MTC 3.1, Third-Party Inspection (SGS / TUV / BV) |

| Applications | Refineries, Chemical Processing, Heat Exchangers, Power Generation |

Stainless Steel 310 310S Tube Fittings Price List

| Price List of Stainless Steel 310 / 310S Tube Fittings | SS 310 Tube Fittings Price in India (INR) | SS 310S Tube Fittings Price in USD | SS 310 / 310S Tube Fittings Price in UAE (AED) |

|---|---|---|---|

| SS 310 Elbow Fittings | ₹ 980 | $ 11.75 USD | 43.10 AED |

| SS 310S Reducer Fittings | ₹ 540 | $ 6.30 USD | 23.15 AED |

| SS 310 Ferrule Tube Fittings | ₹ 2,480 | $ 29.70 USD | 108.60 AED |

| SS 310 Hydraulic Tube Fittings | ₹ 1,320 | $ 15.80 USD | 58.00 AED |

| SS 310S Union Tee Fittings | ₹ 720 | $ 8.70 USD | 31.70 AED |

| SS 310 Tube End Closure | ₹ 1,450 | $ 17.50 USD | 66.30 AED |

Note: Prices are approximate and may vary based on size, thickness, surface finish, and order quantity.

Available Sizes and Grades of Stainless Steel 310 310S Instrumentation Tube Fittings

ASTM A182 Stainless Steel 310 Male Connector for Instrumentation Tube Fittings

Stainless Steel 310S Male Elbow Fitting as per ASTM A479 for Hydraulic and Instrumentation Lines

SS 310 Hex Nipple Tube Fitting UNS S31000 for High Temperature Applications

Stainless Steel 310 Hex Reducing Nipple Tube Fitting for Process and Gas Lines

UNS S31000 Stainless Steel 310 Hex Long Nipple Fitting for Tube Connections

DIN 1.4841 Stainless Steel 310 Hex Coupling for Compression Tube Fittings

ASME SA182 Stainless Steel 310 Reducing Coupling for Instrumentation Tubing

UNS S31000 Stainless Steel 310 Hex Long Nipple Fitting for Tube Connections

DIN 1.4841 Stainless Steel 310 Hex Coupling for Compression Tube Fittings

UNS S31008 Stainless Steel 310S Pipe Cap for Tube End Closure Applications

DIN 1.4845 Stainless Steel 310S Gauge Adaptor for Pressure and Flow Instruments

DIN 1.4841 Stainless Steel 310 Hex Coupling for Compression Tube Fittings

We Supplied a Comprehensive Range Of 310 /310S Stainless Steel Tube Fittings

SS 310 /310S Union Elbow

SS 310 /310S Bulkhead Union

SS 310 /310S Bulkhead Elbow

SS 310 /310S Reducing Union

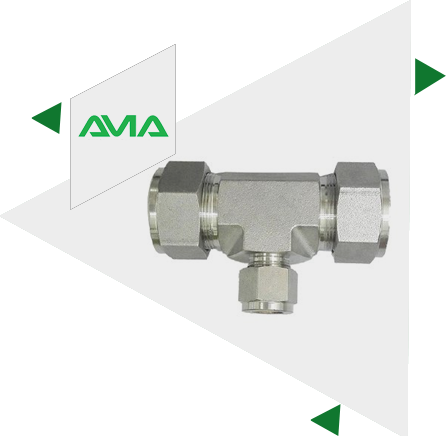

SS 310 /310S Male Branch Tee

SS 310 /310S Male Run Tee

SS 310 /310S Male Elbow

SS 310 /310S Bulkhead Male Connector

SS 310 /310S Union Tee

SS 310 /310S Reducing Union Tee

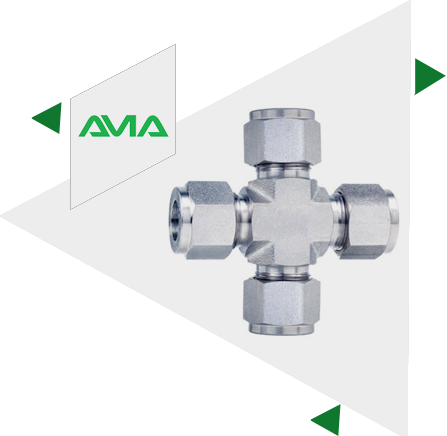

SS 310 /310S Union Cross

SS 310 /310S Male Connector

SS 310 /310S Female Branch Tee

SS 310 /310S Male Adapter

SS 310 /310S Female Adapter

SS 310 /310S Positionable Male Elbow

SS 310 /310S Female Run Tee

SS 310 /310S Female Elbow

SS 310 /310S Bulkhead Female Connector

SS 310 /310S Female Connector

SS 310 /310S Front Ferrule

SS 310 /310S Back Ferrule

SS 310 /310S Tube End Closure

SS 310 /310S Ferrule Nut

Equivalent Grades of Stainless Steel 310 310S Instrumentation Tube Fittings as per ASTM A479 / A276

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 310 | 1.4841 / 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | – | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | – | X8CrNi25-21 |

Chemical Composition of Stainless Steel 310 310S Instrumentation Tube Fittings (UNS S31000 / S31008)

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.015 max | 2.0 max | 0.015 max | 0.020 max | 0.015 max | 24.00 – 26.00 | 0.10 max | 19.00 – 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 | 0.75 max | 19.00 – 21.00 | 53.095 min |

Mechanical Properties of Stainless Steel 310 310S Instrumentation Tube Fittings Tensile Strength & Hardness

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| 310/ 310S | 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

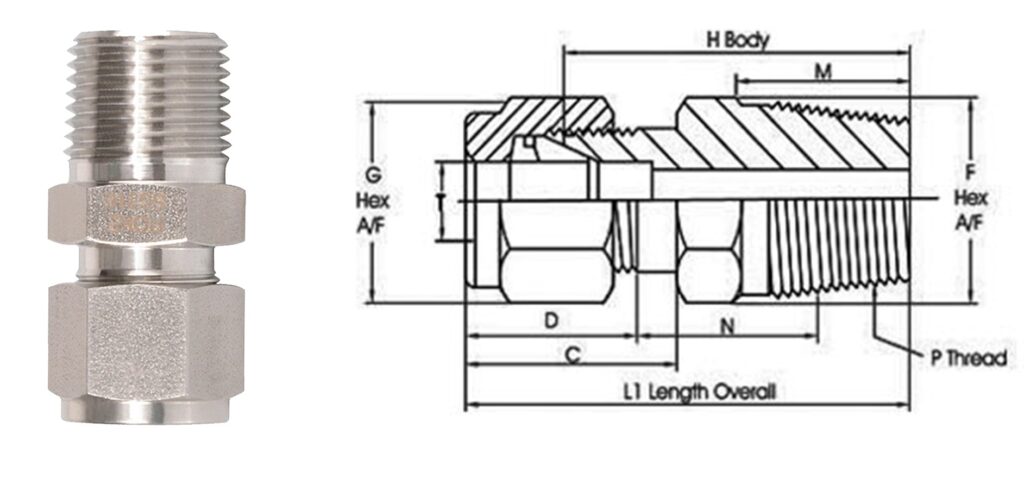

Standard Dimensions of SS 310 310S Instrumentation Tube Fittings for Hydraulic and Compression Systems

| METRIC RANGE | Dimension in mm | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Part | T | P | L1 | M | C | D | F | G | H | N |

| N0 | mmo/d | Length | Body | Nut | Body | |||||

| 4mMC2 | 4 | 1/8′ | 31.35 | 9.53 | 16.67 | 14.29 | 12 | 12 | 24.21 | 10.72 |

| 4mMC4 | 4 | 1/4′ | 35.72 | 14.29 | 16.67 | 14.29 | 14 | 12 | 29.37 | 15.88 |

| 6mMC2 | 6 | 1/8′ | 33.34 | 9.53 | 18.26 | 15.88 | 14 | 14 | 25.40 | 11.11 |

| 6mMC4 | 6 | 1/4′ | 33.34 | 14.29 | 18.26 | 15.88 | 14 | 14 | 30.16 | 12.70 |

| 6mMC6 | 6 | 3/8′ | 38.89 | 14.29 | 18.26 | 15.88 | 19 | 14 | 30.96 | 13.49 |

| 6mMG8 | 6 | 1/2′ | 44.45 | 19.05 | 18.26 | 15.88 | 22 | 14 | 36.51 | 15.88 |

| 8mMC2 | 8 | 1/8′ | 34.53 | 9.53 | 19.05 | 16.67 | 14 | 17 | 26.59 | 11.51 |

| 8mM04 | 8 | 1/4′ | 39.29 | 14.29 | 19.05 | 16.67 | 14 | 17 | 31.35 | 13.10 |

| 10mM02 | 10 | 1/8′ | 35.72 | 9.53 | 19.84 | 17.46 | 17 | 19 | 27.78 | 11.91 |

| 10mMC4 | 10 | 1/4′ | 40.48 | 14.29 | 19.84 | 17.46 | 17 | 19 | 32.54 | 13.49 |

| 10mMC6 | 10 | 3/8′ | 40.48 | 14.29 | 19.84 | 17.46 | 19 | 19 | 32.54 | 13.49 |

| 10mMC8 | 10 | 1/2′ | 46.04 | 19.05 | 19.84 | 17.46 | 22 | 19 | 38.10 | 15.88 |

| 10mMC12 | 10 | 3/4′ | 46.83 | 19.05 | 19.84 | 17.46 | 27 | 19 | 38.89 | 15.08 |

| 12mMC4 | 12 | 1/4′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC6 | 12 | 3/8′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC8 | 12 | 1/2′ | 48.42 | 19.05 | 22.23 | 23.02 | 22 | 22 | 38.10 | 12.70 |

| 12mM012 | 12 | 3/4′ | 49.21 | 19.05 | 22.23 | 23.02 | 27 | 22 | 38.89 | 11.91 |

| 16mMC6 | 16 | 3/8′ | 44.45 | 14.29 | 22.23 | 24.61 | 24 | 27 | 34.13 | 10.32 |

| 16mMC8 | 16 | 1/2′ | 49.21 | 19.05 | 22.23 | 24.61 | 24 | 27 | 38.89 | 11.91 |

| 16mMC12 | 16 | 3/4′ | 49.21 | 19.05 | 22.23 | 24.61 | 27 | 27 | 38.89 | 10.32 |

| 18mMC8 | 18 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 13.49 |

| 18mMC12 | 18 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 18mMC16 | 18 | 1″ | 56.36 | 23.81 | 22.23 | 24.61 | 36 | 30 | 46.40 | 14.29 |

| 20mMC8 | 20 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.60 | 27 | 30 | 40.48 | 13.49 |

| 20mM012 | 20 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 20mM016 | 20 | 1″ | 56.36 | 23.81 | 22.23 | 14.61 | 36 | 30 | 46.04 | 14.39 |

| 25mMC12 | 25 | 3/4′ | 57.15 | 19.05 | 26.19 | 30.96 | 36 | 41 | 45.24 | 11.91 |

| 25mMC16 | 25 | 1″ | 61.91 | 23.81 | 26.19 | 30.96 | 36 | 41 | 50.01 | 13.49 |

| METRIC RANGE | Dimention in Inches | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Part | T | P | L1 | M | C | D | F | G | H | N |

| N0 | mmo/d | Length | Body | Nut | Body | |||||

| 1MC1 | 1/16 | 1/16 | .94 | .38 | .44 | .34 | 5/16 | 5/16 | .78 | .34 |

| 1MC2 | 1/16 | 1/8 | 1.00 | .38 | .44 | .34 | 1/2 | 5/16 | .84 | .41 |

| 2MC1 | 1/8 | 1/16 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC2 | 1/8 | 1/8 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC4 | 1/8 | 1/4 | 1.41 | .56 | .63 | .53 | 9/16 | 7/16 | 1.13 | .50 |

| 3MC2 | 3/16 | 1/8 | 1.21 | .38 | .63 | .54 | 7/16 | 1/2 | .95 | .43 |

| 3MC4 | 3/16 | 1/4 | 1.42 | .38 | .63 | .54 | 9.16 | 1/2 | 1.16 | .54 |

| 4MC1 | 1/4 | 1/16 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .46 |

| 4MC2 | 1/4 | 1/8 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .45 |

| 4MC4 | 1/4 | 1/4 | 1.50 | .75 | .72 | .63 | 9/16 | 9/16 | 1.19 | .50 |

| 4MC6 | 1/4 | 3/8 | 1.51 | .38 | .70 | .60 | 11/16 | 9/16 | 1.19 | .56 |

| 4MC8 | 1/4 | 1/2 | 1.73 | .56 | .70 | .60 | 7/8 | 9/16 | 1.44 | .67 |

| 5MC2 | 5/16 | 1/8 | 1.34 | .38 | .73 | .64 | 9/16 | 5/8 | 1.05 | .46 |

| 5MC4 | 5/16 | 1/4 | 1.52 | .56 | .73 | .64 | 9/16 | 5/8 | 1.23 | .54 |

| 6MC2 | 3/8 | 1/8 | 1.38 | .56 | .76 | .66 | 5/8 | 11/16 | 1.09 | .48 |

| 6MC4 | 3/8 | 1/4 | 1.57 | .75 | .76 | .66 | 5/8 | 11/16 | 1.28 | .57 |

| 6MC6 | 3/B | 3/8 | 1.57 | .75 | .76 | .66 | 11/16 | 11/16 | 1.28 | .56 |

| 6MC8 | 3/B | 1/2 | 1.79 | .56 | .76 | .66 | 7/8 | 11/16 | 1.50 | .67 |

| 6MC12 | 3/8 | 3/4 | 1.82 | .56 | .76 | .66 | 1-1/16 | 11/16 | 1.53 | .68 |

| 8MC4 | 1/2 | 1/4 | 1.17 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .47 |

| 8MC6 | 1/2 | 3/8 | 1.71 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .46 |

| 8MC8 | 1/2 | 1/2 | 1.90 | .56 | .86 | .90 | 7/8 | 7/8 | 1.50 | .54 |

| 8MC12 | 1/2 | 3/4 | 1.93 | .75 | .86 | .90 | 1-1/16 | 7/8 | 1.53 | .55 |

| 10MC6 | 5/8 | 3/8 | 1.74 | .56 | .86 | .96 | 15/16 | 1 | 1.34 | .43 |

| 10MC8 | 5/8 | 1/2 | 1.93 | .75 | .86 | .96 | 15/16 | 1 | 1.53 | .51 |

| 10MC12 | 5/B | 3/4 | 1.93 | .75 | .86 | .96 | 1-1/16 | 1 | 1.53 | .49 |

| 12MC8 | 3/4 | 1/2 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/8 | 1.59 | .57 |

| 12MC12 | 3/4 | 3/4 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/18 | 1.59 | .55 |

| 12MC16 | 3/4 | 1 | 2.21 | .94 | .86 | .96 | 1-3/16 | 1-1/8 | 1.81 | .68 |

| 16MC12 | 1 | 3/4 | 2.26 | .75 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.78 | .55 |

| 16MC16 | 1 | 1 | 2.45 | .94 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.97 | .65 |

Related Products

- Stainless Steel Products

- Stainless Steel 304 Tube Fittings Supplier

- Stainless Steel 304L Tube Fittings Supplier

- Stainless Steel 316 Tube Fittings Supplier

- Stainless Steel 316Ti Tube Fittings Supplier

- Stainless Steel 316L Tube Fittings Supplier

- Stainless Steel 317L Tube Fittings Supplier

- Stainless Steel 347H Tube Fittings Supplier

- Stainless Steel 904L Tube Fittings Supplier

- SMO-254 Tube Fittings Supplier

Applications of Stainless Steel 310 310S Instrumentation Tube Fittings in Industrial Systems

The stainless steel 310/310S Instrumentation tube fittings are frequently used in the industries which require high level of corrosiveness and pressure and thermal control. They are splendid in oxidation as well as mechanical strength and can find application in petrochemical, oil and gas, power generation and in food processing units. These fittings perform leak free in the systems of steam instrumentation, hydraulic instrumentation systems and gas instrumentation systems. In process industries, sugar industries are also fitted with SS 310/310S that not only have the dimensional accuracy and clean flow properties but also enable the plants to run in the same manner in both low and high temperature and pressure conditions.

Application Industry

For More Information About Stainless Steel 310 /310S Instrumentation Fittings please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Testing and Quality Inspection of Stainless Steel 310 310S Instrumentation Tube Fittings

We also make sure that all Stainless steel 310/310S Instrumentation Tube Fittings pass a high-quality check prior to labeling and shipping to you. All the fittings were checked according to correct dimensions, pressure integrity and corrosion resistance. We also perform destructive and non-destructive testing on our own in compliance with the ASTM and ASME requirements. The whole process assures the product reliability of critical instrumentation, hydraulic, and pneumatic systems.

Testing Procedures Include:

- Eddy Current Examination

- Hydrostatic Pressure Testing

- Pitting Resistance and Intergranular Corrosion Test

- Positive Material Identification (PMI)

- Dimensional and Visual Inspection

Packing and Delivery of Stainless Steel 310 310S Instrumentation Tube Fittings

Our packaging is safe and efficient to ensure every product of SS310/310S Instrumentation Tube Fitting is received by the customer in original condition. All the products are packed carefully and high quality materials used in exports are used to ensure that the product is not ruined in the process of handling and transportation. They also offer tailor packaging as per the requirement of the client and specifications of the destination.

Packaging Methods Include:

- Wooden Boxes and Pallets

- Shrink-Wrapped and Bubble-Wrapped Bundles

- Carton Boxes and Crates

- Marked Packaging with Product Details and Batch Numbers

Frequently Asked Questions for Stainless Steel 310 and 310S Tube Fittings

Stainless Steel 310 / 310S Tube Fittings Tube fittings offer leak free connections in instrumentation, hydraulic systems and pneumatic systems. They are quite good in oxidation and corrosion resistance and thus they can be applied in a refinery, chemical plant, power generation, and heat-exchanger, where high stability and dimensional accuracy are critical.

The most important difference is the carbon content. SS 310 contains slightly more carbon hence is more resistant to high temperature and SS 310S contains less carbon hence is weldable and gives less possibility of precipitation of carbide. The two grades offer good corrosion and oxidation resistance at high temperatures.

SS 310 and 310S Tube Fittings conform to ASTM A479 and A276 material standards and correspond to UNS S31000 (310) and UNS S31008 (310S) grades. Equivalent European and DIN grades include WNR 1.4841 and 1.4845. These ensure consistent mechanical properties, chemical composition, and dimensional reliability.

Yes. The SS 310 and 310S Tube Fittings have the capability of continuous service up to 1100 °C (2010 °F) in oxidizing conditions. Their carburization, oxidation, and scaling resistance is excellent and is mainly used in furnaces, boilers, and exhaust systems due to their chromium-nickel composition.

Aashish Metals is also reputed to offer a complete range of products including ferrule fittings, hydraulic adapters, compression fittings, tube-to-union connectors, male elbows, reducer, couplings, and pipe tube. All of them are machine-produced to perfection and certified to MTC 3.1 so that they can be traced in terms of quality.

Checking of individual fittings is done dimensionally, under hydrostatic test, eddy current test and Positive Material Identification (PMI). The tests are guided by the ASTM and ASME quality requirements so as to offer pressure integrity, resistance to corrosion and performance reliability under the harsh service conditions.

Yes. Aashish Metals has customization of tube fitting sizes, surface finishes, and export grade packaging by the use of wooden boxes, shrink-wraps, and pallets. Items are packed in safes with identification tags and paperwork to maintain the safe delivery and trace of the products all over the world.

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.

Products

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal