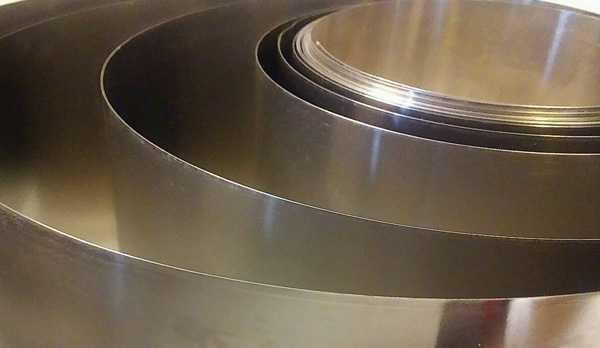

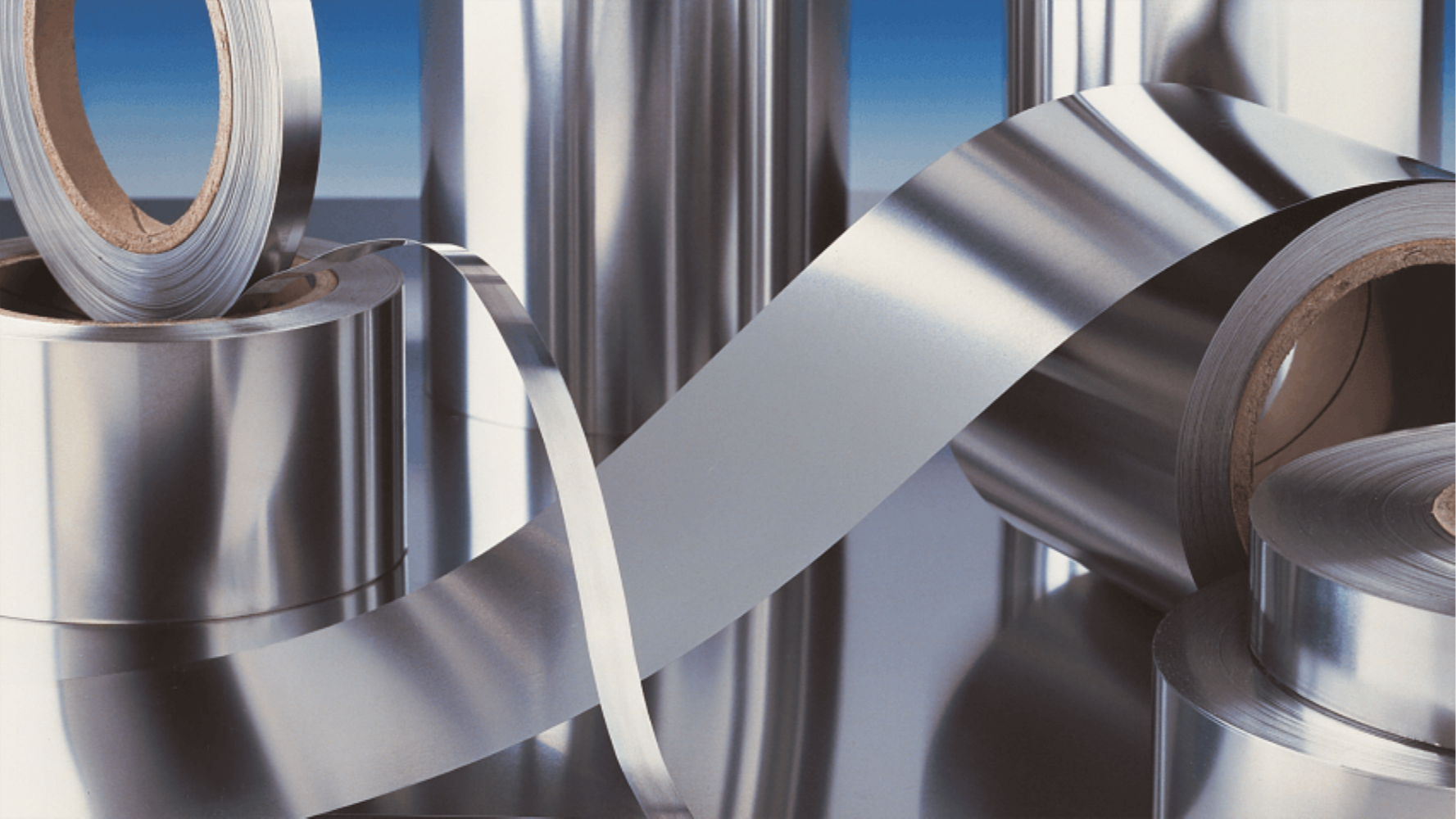

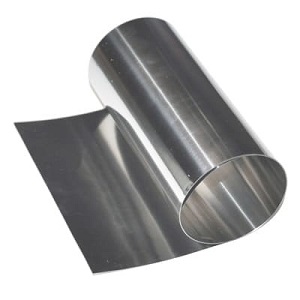

Aashish Metals is a reputable manufacturer and distributor of metal shims to meet the need of various industries in India. Our main business is manufacturing precision alignment shims, precut shims, and laminated shims made up of high-quality stainless steel 304 / 316, brass and copper. Each of the shims is designed to provide proper leveling, spacing and alignment in machinery, pumps, compressors and structural assemblies, where tolerances on a micron level are important.

Our custom shim is available in sheet, strip, and precut form with a thickness tolerance of 1.0 mm to 0.01 mm and a tolerance of ± 0.005 mm. All the pieces of this material burrs are removed, finishes and inspected to the standards of ASTM and IS in terms of dimensional accuracy and durability. Clients use us to obtain machine alignment shims, motor base shims and die-set shims that will provide correct installation and longer equipment life.

Aashish Metals, possessing more than twenty years of experience in the manufacturing sphere, incorporates a high level of cutting and polishing equipment with rigid quality control into manufacturing of high-performance stainless steel, brass, and copper shims. It might be that you need prepared shim packs that are already shipped or customized thickness mixes and we can make you quotations quickly, issue material test certificates and deliver to your door in a district-wide manner on every order.

Shims Manufacturer in India, Shims Dealer, Shims Exporter, Precision Shims, Machine Alignment Shims, Precut Shims, Laminated Shims, Stainless Steel Shims, Brass Shims, Copper Shims, ASME SA 240 Shims, ASTM A240 Stainless Steel Shims, SS Shim Sheets, Stainless Steel Shim Stock, Stainless Steel Hot Rolled Shims, Stainless Steel Cold Rolled Shims, Industrial Shims Supplier, Custom Cut Metal Shims, Shims Stockist in India.

Table of Content

- Specification of Shims

- Material Grades Available in Metal Shims

- Shims Products List

- What Should Be Considered When Choosing Shims

- Quality and Assurance – Delivering Precision Shims with Unmatched Reliability

- Packaging Excellence – Secure Delivery by Expert Shims Manufacturers

- Aashish Metals – Certified Excellence in Shim Manufacturing

- Applications of Shims

Specification of Shims

| Specification | Details |

|---|---|

| Specifications | ASTM A240, ASME SA240, IS 319, ASTM B152 |

| Thickness | 0.02mm – 5.0mm |

| Shims Width | 3.2mm – 1500mm |

| Length | Up to 2500mm (custom cut available) |

| Tolerance | ± 0.005mm (as per client requirement) |

| Material Grades | Stainless Steel 304 / 304L / 316 / 316L, Brass, Copper |

| Hardness | Soft, Half Hard, Full Hard |

| Form | Sheet, Strip, Precut, Laminated, Shim Stock |

| Finish | Mill Finish, Bright, Polished, Satin, Mirror |

| Applications | Machine Alignment, Leveling, Motor Mounting, Die Setup, Structural Adjustment |

| Packaging | Plastic-Wrapped Bundles, Wooden Boxes or Export-Grade Crates |

Confused About the Right Shim?

Material Grades Available in Metal Shims

Stainless Steel Shims

Brass Shims

Copper Shims

Monel Shims

Inconel Shims

Duplex Shims

Shims Products List

Aashish Metal & Alloys is a leading trader of Precut Shims, which are metal spacer components primarily alloyed with carbon. These shims find wide use across industries, especially in plants and refineries where fluids and gases are transported under high pressure and temperature. We offer pipes of various sizes that meet all required specifications for tasks like flanging, bending, and welding. With high tensile strength and excellent performance, these shims are trusted in heavy engineering and even some automotive applications.

What should be considered when choosing Shims?

The correct choice of metal shim is critical to the required accuracy of fitting, acceptable performance, and durability of the industrial assembly. One of the functional and environmental factors, which influence the accuracy, safety, and durability of the equipment directly, is the choice of shim material and design.

- Material Properties: Various materials provide various mechanical advantages. Stainless steel shims are also good in terms of corrosion and heat resistance, and therefore, they can be used in chemical, thermal, and structural applications. Brass and copper shims have better electrical conductivity and are commonly used in electrical, marine or sealing applications. Selecting the right shim makes the shim work in an even manner under pressure or load.

- Operating Conditions: Consider the location and manner of operation of the shim. As an exemplar, oxidation-resistant metals are needed in high temperature environments whereas corrosion-resistant alloys are needed in humid or salt-contaminated environments. It is to ensure that the material does not deform when under operation.

- Usage Requirements: Decide on whether the shim is going to be used in a static load or dynamic load. Friction behavior, wear resistance and surface finish are also important in moving assemblies. The choice of a shim to fit a load type, tolerance of its alignment, and vibration level is a guarantee of high reliability in the long term and minimal maintenance.

Quality and Assurance – Delivering Precision Shims with Unmatched Reliability

Aashish Metals assured that whatever type of shims we are marking goes under the strict quality checks and advanced testing to ensure the accuracy, durability, and match with the international standards. Our in-house inspection maintains the dimensional accuracy and mechanical integrity.

Our Testing Process Includes:

- Positive Material Identification (PMI)

- Spectrochemical Analysis for Alloy Verification

- Tensile and Hardness Testing

- Micro and Macro Structural Examination

- Pitting and Intergranular Corrosion (IGC) Tests

- Flaring and Flattening Checks

- Impact and Bend Tests for Formability

- Ultrasonic and Eddy Current Testing for Surface Integrity

Every shima is supplied with the Mill Test Certificate that matches the international standards like ASTM, ASME, and ISO, which ensure the top-quality performance in all industrial applications.

Packaging Excellence – Secure Delivery by Expert Shims Manufacturers

We understand the importance of safety and reliable packaging and especially when shipping globally. At Aashish Metals, we follow the strict rules of packing to prevent the material from damage and corrosion during handling and transport.

Our Packaging Process Includes:

- Moisture-proof plastic or VCI wrapping for surface protection

- Carton boxes, foam separators, or shrink-wrapped bundles

- Wooden boxes and export-grade pallets for bulk deliveries

- Individual labeling with grade, size, and batch identification

Our logistics team ensures timely dispatch and global reach, delivering your shims safely to every corner of India and abroad.

Aashish Metals – Certified Excellence in Shim Manufacturing

Get the experience of quality, accuracy and dependability that make Aashish Metals. We are ISO 9001: 2015 certified in manufacturing and inspection that ensures that the quality of our materials is in line with those of other countries.

We provide this material to different Industries in India, Middle East, Europe and Asia. All shims are indicators of our dedication to designing engineering precision and customer satisfaction.

Certifications:

- ISO 9001:2015 – Quality Management System

- ASTM & ASME Material Compliance

- In-House Test Reports and MTCs with Each Shipment

GLOBAL SERVICE

Today our client list stretches to around 30 countries in all over world.

ON TIME DELIVERY

We provide your order in the best possible leed times and reasonable price.

24/7 SUPPORT

we service clients from different industries such as Pharmaceutical

Applications of Shims

Aashish Metals makes precise metal shims that are well designed for accurate spacing, alignment across a wide range of industrial uses. Our stainless steel, brass, and copper shims are made with high-strength, corrosion resistant for a critical environment.

Common Applications Include:

- Machinery Alignment:

Used for precise leveling and alignment of pumps, motors, turbines, compressors, and gearboxes to reduce vibration and mechanical stress. - Tool and Die Setup:

Helps maintain exact die height and parallelism in stamping, molding, and press tools for consistent production quality. - Structural and Construction Work:

Applied for base plate alignment, column leveling, and heavy equipment installation in structural and civil engineering projects. - Automotive and Aerospace Components:

Supports tolerance control and fit adjustments in engine assemblies, brake systems, and airframe structures where precision is critical. - Power Generation and Petrochemical Plants:

Ensures accurate equipment positioning, flange alignment, and thermal expansion compensation under high pressure and temperature. - Maintenance and Repair Operations:

Used during machinery calibration, inspection, and field maintenance to achieve correct clearances and restore alignment accuracy.

Each Aashish Metals shim is engineered for reliability and performance in demanding operating environments.

For More Information About Shims please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Frequently Asked Questions About Shims

Metal shims are very thin excavated sheet metal utilized in positioning and alignment of components and masking of machinery, pumps, dies and construction assembly. Our stainless steel, brass and copper shims are used in Aashish Metals so that we can reach the exact tolerances, vibration and stable installations that can be made in the industrial uses.

The most suitable shim material is dependent on the working environment. Stainless steel shims are also good in high temperature and corrosive environments. Brass shims are resistant to saltwater and should be used in the marine or electrical industry, whereas copper shims are superior conduction thermal and electrical and should be used in HVAC or transformers.

Aashish Metals produces shims with a tight tolerance of up to +-0.005mm, thickness of 0.02 mm to 5.0 mm and in thickness combinations, sizes, and shapes based on project or equipment needs.

The choice of the correct shim depends on the load condition, temperature, exposure of corrosions and tolerance. As an illustration, stainless steel would be the best choice in a heavy workload or outdoor application and brass would be the best choice in low-friction assemblies. We assist you in deciding the most appropriate shim in your operating environment with the help of our technical experts.

Yes. Aashish Metals provides pre-cut and custom-cut shims of any clientele. We have various types of sheet, strip, laminated and shim stock with different kinds of surface finish to satisfy the exact alignment and assembling requirements.

Absolutely. Our shims are all packed in export grade wooden crates or moisture-proof bundles with correct labeling and Mill Test Certificates (MTC). We export repeatedly to the Middle East, Europe and Asia, making the international deliveries safe and timely.

Shims are manufactured in accordance with ASTM A240, ASME SA240 and ISO 9001:2015 quality standards. The batches are subjected to mechanical and chemical tests to ensure the consistency in performance and dimension accuracy.

Partner with Aashish Metals for Reliable Shim Solutions

PRODUCT RANGE

Products

- Materials

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- Thank You For Connecting

- Duplex and Super Duplex Steel Pipes and Tubes

- Duplex and Super Duplex Steel Threaded Fittings Manufacturer and Supplier

- Duplex Steel S31803 S32205 and Super Duplex S32750 S32760 Pipe Fittings

- Duplex S31803 S32205 Socket Weld Fittings Manufacturer

- Duplex and Super Duplex Steel Socket Weld Fittings

- Duplex and Super Duplex Steel Tube Fittings

- Stainless Steel 316 / 316L Pipes & Tubes

- Stainless Steel 321 Pipes & Tubes

- Inconel Pipes and Tubes

- Home uat

- Stainless Steel Pipe Fittings Manufacturer and Supplier

- Stainless Steel Pipes and Tubes

- C17200 Beryllium Copper

- C17300 Beryllium Copper

- C17500 Beryllium Copper

- BERYLLIUM COPPER STRIP & COIL

- Beryllium Copper C17200 Wire

Special Products

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.