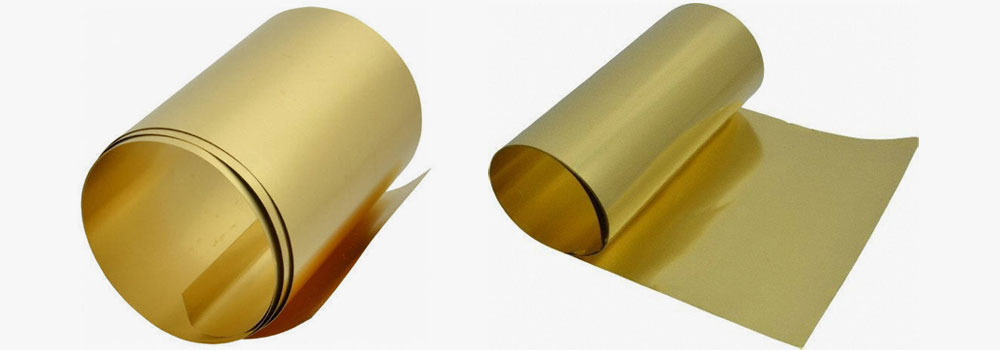

Brass shims are made with the precise compositing and heating technique and are widely used to fill the gaps, adjust alignment, support parts, and the construction system. They are very popular for it’s strength, corrosion resistance, flexibility, and excellent electrical and heat conductivity.

At Aashish Metal & Alloy, we manufacture and supply a comprehensive range of different brass shim products, which include brass cladding shims, brass shim sheets, brass hot rolled shims, and brass polished shims. Each of these shims is made to deliver consistent performance and superior mechanical stability, making them a suitable choice for aerospace, automotive, oil and gas, electrical, and construction applications.

Our high-quality brass shims material comes with excellent workability and wear resistance that make it perform well while maintaining strength under harsh conditions. Whether you want custom-cut shims, thin foil sheets, or any heavy-duty stock rolls, our manufacturing experts provide the highest quality of material that meets your needs and international standards.

BRASS SHIM FOIL, PLATE, 85/15 AND C260 BRASS SHIMS, HARD AND POLISHED TYPES, AND CUSTOM ROLL VARIANTS

Controlled improvements in titanium, niobium and vanadium are added to brass shims at precise amounts to have excellent grain structure and precipitation hardening. Another advantage of these elements is that they increase mechanical strength and corrosion resistance and are therefore suitable in demanding applications. Aashish Metal and Alloys have stocks of C260 and 85/15 brass shims that are fabricated using high metallurgical properties that are bound to provide high durability and performance. Their microstructure consists of polished layers of cementite in the pearlite and ferrite which is a resistive material to rust as compared to most carbon steel. The development of each brass shim is to a high-quality ferrite matrix with a small content of pearlite and the extrusion process to give a balanced and symmetrical ferrite grain structure.

These shims are longitudinal grains that are specifically designed to reduce edge cracking and to support high tensile stresses. Directional weaknesses are minimized through the control of the formation of sulfides. Consequently, these brass shim foils and plates, as well as rollers, are commonly applied in cranes, bridges, vehicles, roller coasters, and heavy-duty industrial equipment where high strength to weight ratios are absolutely important. Addition of copper, vanadium, niobium, and titanium further enhances the ferrite-pearlite matrix, good distribution of carbides to guarantee high toughness, stability and durability at stress.

Brass Shim Foil, Brass Shim Plate, 85/15 Brass Shims, Brass Hard Shims, and Brass Shim Rolls Stockist in India.

In order to build up a complex grain length and precipitation hardening, brass shim also contains a very minor amount of titanium, niobium, and vanadium. Precipitation hardening is strengthening it, nevertheless and it has improved corrosion resistance. Aashish Metals stocks brass shims engineered with these advanced properties making them suitable for a wide range of critical applications. Because of their advanced cementite layers in pearlite and ferrite (a type of natural iron), as well as their scarcity of pearlite, they are more resistant to rust than maximum carbon steels. Nevertheless, it ends with a very high-quality grain ferrite matrix in place of very little pearlite. In addition, it has a highly deformed austenite shape during the extrusion process, which cools to a good symmetrical ferrite shape.

They are much like the longitudinal grain, which is extra predicted to crack within the area of an outside edge, for the purpose that it reviews tensile freights. This directional feature has been significantly reduced, which is addressed through sulfide form control. Meanwhile, they’re being utilized in cranes, bridges, automobiles, trucks, roller coasters and different systems that can be designed to keep massive quantities of pressure or require a top-notch strength-to-weight relative amount. Elements, which include copper, vanadium, niobium, titanium and others, are proposed to extrude the microstructure of those steels. It is through a big ferrite-pearlite aggregate to make a very nice dispersal of alloy carbides in an extra or much less natural ferrite matrix.

Specifications Table for Duplex Steel UNS S31803 Fasteners

Our brass shims come in a broad selection of thicknesses, widths and lengths to satisfy a variety of industrial needs. Reputable mills provide these premium shims, guaranteeing accuracy and longevity in any application.

| Specification | Details |

|---|---|

| Specifications | ASTM A240 / SA240 |

| Thickness | 0.02mm – 5.0mm |

| Width | 3.2mm – 1500mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, Hairline, Scotch Brite, Satin Finish, NO.8, BA. |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard |

| Make | Jindal, Bahru, Posco Korea, Posco Thainox, Columbus, Acerinox, Aperam, Tisco, Nisshin, Nippon And Many More Mills. |

Brass Shims Quality and Test reports

We offer thorough quality assurance using stringent testing and third-party inspections to guarantee the highest standards for total transparency. Our brass shims are supported by comprehensive test reports and mill certificates.

- Third Party Inspection

- EN 10204/3.1B

- 100% Radiography Test

- Raw Materials Certificate

- Mill test

We Supplied a Comprehensive Range Of Brass Shims

Types Of Brass Shims

Explore our selection of brass shims, which come in a variety of shapes to accommodate a range of industrial uses. Find the ideal solution for your requirements, whether it’s shim sheets or brass shim stock.

C260 Brass Shims

Brass Shim Stock

Brass Shim Sheet

Brass Shims

Brass Shims Dimensions

Our brass shims come in a range of sizes, guaranteeing accurate and dependable operation. The standard measurements, which include width, length, slot width and slot depth are listed below.

| Width | Length | Slot Width | Slot Depth |

|---|---|---|---|

| 2″ | 2″ | 1-1/4″ | 1-9/32″ |

| 3″ | 3″ | 1-5/8″ | 2-1/8″ |

| 4″ | 4″ | 2″ | 2-3/4″ |

| 5″ | 5″ | 2-1/2″ | 3-5/8″ |

| 6″ | 6″ | 5/8″ | 4″ |

| 8″ | 8″ | 7/8″ | 6″ |

Brass Shim Weight Chart

The weight of brass shims per square meter (kg/m2) is shown in this chart according to their various thicknesses and diameters.

| THICKNESS IN MM | SIZE IN MM | WEIGHT KG/M2 | ||

|---|---|---|---|---|

| 2000 X 1000 | 2500 X 1250 | 3000 X 1500 | ||

| 0.18 | 2.88 | – | – | 1.44 |

| 0.20 | 3.20 | – | – | 1.60 |

| 0.22 | 3.52 | – | – | 1.76 |

| 0.24 | 3.84 | – | – | 1.92 |

| 0.27 | 4.32 | – | – | 2.16 |

| 0.28 | 4.48 | – | – | 2.24 |

| 0.32 | 5.12 | – | – | 2.56 |

| 0.38 | 6.08 | – | – | 3.04 |

| 0.44 | 7.04 | 11.00 | – | 3.52 |

| 0.50 | 8.00 | 12.50 | – | 4.00 |

| 0.56 | 8.96 | 14.00 | – | 4.48 |

| 0.63 | 10.08 | 15.75 | – | 5.04 |

| 0.75 | 12.00 | 18.75 | – | 6.00 |

| 0.88 | 14.08 | 22.00 | – | 7.04 |

| 1.00 | 16.00 | 25.00 | 36.00 | 8.00 |

| .1.13 | 18.08 | 28.25 | 40.00 | 9.04 |

| 1.25 | 20.00 | 31.25 | 45.00 | 10.00 |

| 1.38 | 22.03 | 34.50 | 50.00 | 72.00 |

| 1.50 | 24.00 | 37.50 | 54.00 | 12.00 |

| 1.75 | 28.00 | 43.75 | 63.00 | 14.00 |

| 2.00 | 32.00 | 50.00 | 72.00 | 16.00 |

| 2.25 | 36.00 | 56.25 | 81.00 | 18.00 |

| 2.50 | 40.00 | 62.50 | 90.00 | 20.00 |

| 2.75 | 44.00 | 68.75 | 99.00 | 22.00 |

| 3.00 | 48.00 | 75.00 | 108.00 | 24.00 |

| 3.25 | 52.00 | 81.25 | 117.00 | 26.00 |

| 3.50 | 56.00 | 87.50 | 126.00 | 28.00 |

| 3.75 | 60.00 | 93.75 | 135.00 | 30.00 |

| 4.00 | 64.00 | 100.00 | 144.00 | 32.00 |

| 4.25 | 68.00 | 106.25 | 153.00 | 34.00 |

| 4.50 | 72.00 | 112.50 | 162.00 | 36.00 |

| 5.00 | 80.00 | 125.00 | 180.00 | 40.00 |

| 5.50 | 88.00 | 137.50 | 198.00 | 44.00 |

| 6.00 | 96.00 | 150.00 | 216.00 | 48.00 |

| 6.50 | 104.00 | 162.50 | 234.00 | 52.00 |

| 7.00 | 112.00 | 175.00 | 252.00 | 56.00 |

| 7.50 | 120.00 | 187.50 | 270.00 | 60.00 |

| 8.00 | 128.00 | 200.00 | 288.00 | 64.00 |

C260 Brass Sheet and Plate Weight Chart

| Thickness | Width | Length | Lbs per sq. ft. | Approx. Lbs. Per Sheet |

|---|---|---|---|---|

| 0.020 | 36 | 96 | 0.9 | 21.3 |

| 0.025 | 36 | 96 | 1.1 | 26.6 |

| 0.032 | 36 | 96 | 1.4 | 34.1 |

| 0.040 | 36 | 96 | 1.8 | 42.6 |

| 0.050 | 36 | 96 | 2.2 | 53.2 |

| 0.0625 | 36 | 96 | 2.8 | 68.1 |

| 0.080 | 36 | 96 | 3.6 | 85.2 |

| 0.093 | 36 | 96 | 4.1 | 99.0 |

| 0.125 | 36 | 96 | 5.5 | 133.1 |

| 0.1875 | 36 | 96 | 8.3 | 199.6 |

| 0.250 | 36 | 96 | 11.1 | 266.1 |

| 0.375 | 36.5 | 96.5 | 16.6 | 399.2 |

| 0.500 | 36.5 | 96.5 | 22.2 | 532.2 |

260 Brass Chemical Composition (%max., unless shown as range or min.)

| Cu | Fe | Pb | Zn | |

|---|---|---|---|---|

| Min./Max. | 68.5-71.5 | .05 | .07 | Rem. |

| Nominal | 70.0 | – | – | 30.0 |

| Note: Cu + Sum of Named Elements, 99.7% min. | ||||

We Keep Bulk Stock Of Brass Shims, Ready Brass Shim At Our Stockyard, Contact Us For Free Sample & Stock List.

Related Products

Price list of Brass Shim

Request the latest Brass Shim List. Please click on the request a quote button or click here to request the updated price list and ready stock information along with your requirement. Aashish Metal & Alloys maintains a stock of all standard items and can export them at the best price for brass shims.

We supply various Brass Shims.

Aashish Metal & Alloys is a highly acclaimed manufacturer & supplier of brass shims, offering more than 3000 varieties in all types of brass in all sizes, with more than 52 countries worldwide.

| Brass Shim Kit Stockholder | Brass Shim Strips Distributor |

| Hot Rolled Brass Shims | Brass Shims Supplier |

| Hard Brass Shims | Brass Cut Shims |

| Brass Ready Cut Shims | Custom Brass Shims Suppliers In India |

| Brass Mirror Polish Shims | Brass Polished Shims |

| Brass Shim Coil Wholesaler | Brass UNS C26800 Shims Exporter |

| Brass Shim Rings Dealer | Brass C260 / C26000 Shim |

| Brass CR Shims Stockist | Brass Shim Supplier |

| Cold Rolled Brass Shims | Thin Brass Shims Exporter |

| Brass C23000 Shims Exporter | Brass C21000 Shims Manufacturer |

| Brass Round Shims | Brass HR Shims Stockholder |

| Brass Shims Stock | Brass C330 / C33000 Shims |

| Brass Hard Shims | Brass C27200 Shim |

| Brass Cladding Shims Supplier | Brass Shims Distributor |

Application Of Brass Shims

Application Industry

For More Information About Brass Shims please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Frequently Asked Questions About Brass Shims

Brass shims are used to fill gaps and align components in machinery and structures. They ensure precise spacing and enhance performance in industrial applications.

Brass shims can be cut using shears, snips, or laser cutting. These methods allow accurate shaping and sizing for specific requirements.

Steel shims are stronger but less corrosion-resistant. Brass shims offer excellent corrosion resistance and better electrical conductivity.

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

PRODUCT RANGE

Products

- Materials

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- Thank You For Connecting

- Duplex and Super Duplex Steel Pipes and Tubes

- Duplex and Super Duplex Steel Threaded Fittings Manufacturer and Supplier

- Duplex Steel S31803 S32205 and Super Duplex S32750 S32760 Pipe Fittings

- Duplex S31803 S32205 Socket Weld Fittings Manufacturer

- Duplex and Super Duplex Steel Socket Weld Fittings

- Duplex and Super Duplex Steel Tube Fittings

- Stainless Steel 316 / 316L Pipes & Tubes

- Stainless Steel 321 Pipes & Tubes

- Inconel Pipes and Tubes

- Home uat

- Stainless Steel Pipe Fittings Manufacturer and Supplier

- Stainless Steel Pipes and Tubes

- C17200 Beryllium Copper

- C17300 Beryllium Copper

- C17500 Beryllium Copper

- BERYLLIUM COPPER STRIP & COIL

- Beryllium Copper C17200 Wire

Special Products

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.