In manufacturing and industrial processes, the piping systems have extensive use of valves in controlling the flow of liquids, gases, and slurries. Within the oil and gas industry, power production, chemical manufacturing, and water treatment, among other industries, valves are important in the efficient, safe, and accurate functioning of fluid-filled systems.

To help bring into light the different considerations that should be made when making a choice of valve that best suits a particular application, this blog gives a good overall understanding of valves, their functions and the various types of the valves in piping used in different industries.

What Are Valves and Why Are They Important in Piping Systems?

A valve is a mechanical apparatus that is used in fluid systems to control, regulate, direct, isolate or mix the flow and pressure of a fluid by obstructing the passage in a pipeline system. When the valve is open the flow path is not blocked and fluid is able to flow from an area of higher pressure to an area of lower pressure. By partially or completely obstructing this passage, the valve may partially or completely inhibit flow as it is required to do.

From a technical point of view, valves are regarded as pipe fittings, however, because of their critical functions, their wide range of designs and operating modes, valves are generally classified independently of the usual fittings. Valves are also a major part of total system cost of many industrial plants, where valves account for almost 30% of all piping costs.

Different Types of Valves in Piping Systems

Pipes include valves as an inseparable part of the mechanism as they provide the opportunity to control the flow of the fluid through tools which are specially designed to perform specific tasks and work within the defined conditions. There are various types of valves to meet various needs such as flow control, isolation, directional and backflow. The following list summarizes the most prominent types of valves that are used in industrial applications with piping, as each of them has its unique features that apply to specific applications.

- Forged Globe Valves: Forged globe valves make use of linear motion to adjust flow to provide accurate throttling and shutoff. Their cast bodies can withstand high rates of pressure and temperature which makes them viable in employing steam, oil and chemicals.

- Cast Steel Globe Valves: Cast steel globe valves are made of cast body. They provide good flow control and strict sealing of the pipelines that carry water, steam, or corrosive water, and are usually utilized in power and process industries.

- Angle-Type Globe Valves: The globular valves of the angle type have an inlet and outlet at 90 degree, hence it is best suited to installations which demand to change the direction of the pipe and minimize the pressure drop. They occur in water supply, power, as well as chemical services.

- Forged Gate Valves: In a forged gate valve, there is a bi-directional through a lift on a gate between seats. Their forged structure is that which is applicable to high-pressure or critical service in oil, gas and power plants.

- Cast Steel Gate Valves: These valves are used to block or allow flow using a flat gate. They are built in cast steel and they are excellent in high-pressure handling and are normally applied in water, oil, gas and steam lines as an excellent isolation technique.

- Knife-Edge Gate Valves: The knife-edge valves have a sharp-edged gate, which cuts through slurries or viscous fluids. They are used in pulp, mining and wastewater applications, avoiding clogging, and offer reliable shutoff even using challenging media.

- MonoFlange Valves: MonoFlange valves combine several functions within a compact flange, reducing the leaks and the size of the installation areas. Their wide application of instrumentation and the control of the processes is efficient with regard to the isolation and ventilation.

- Check Valves: Check valves allow one-way flow and do not allow it to run backwards in an automatic mechanism. They are widespread in the water, oil and process systems to safeguard pumps and equipment against reverse flow.

Classification of Valve Based on Function

Piping systems contain valves which are installed to carry out different functions. Most types of valves in piping are used to either start or stop flow, control flow and pressure, redirect flow or increase process safety. On flow control, piping valves are divided into two categories of use as isolation or regulation.

- Isolation valves: The isolation valves are made to either almost prevent flow of fluids or permit their free flow. They are usually not known to work in the continuous mode operating in an only half open position, as this may lead to improper flow control or faster wearing out. Under piping diagrams, different symbols are used to denote the different types of isolation valve.

- Regulation valves: These valves are used in cases where the regulation of pressure and foaming flow of fluids is needed down to the latter. They can safely and efficiently be used in processes that require intermediate open or closed conditions. The different varieties of regulation valves employed in piping are more accurately controlled than the isolation valves.

Some designs of the valves can be used in isolation and also for regulating, but some other valve designs fit well in only one of the two functions. When evaluating valve types, one should always consider the specific operational requirements and consult standardized piping valve symbols in engineering documentation.

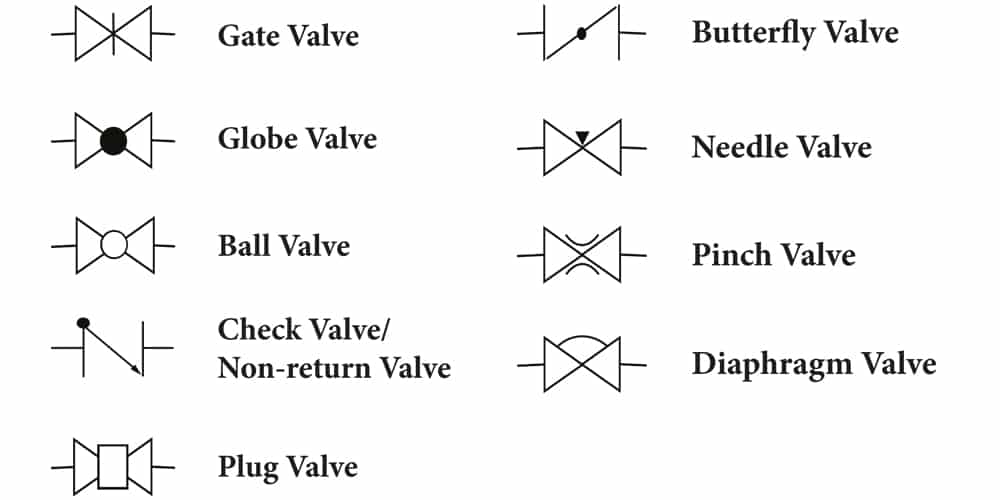

Piping Valve Symbols Explained

The table below lists the different types of valves and their corresponding P&ID symbols. The most commonly used types of valves are gate valves, globe valves, check valves and ball valves.

How to Choose the Right Type of Valve

In order to choose the right valve to be used in a piping system, one must ascertain the purpose in which the valve is to be used; to halt fluid flow, to control the flow, or to change direction of flow. Then, the operating conditions of the system such as the nature of the fluid, the amount of the pressure and temperature should be considered. Last but definitely not the least, it is imperative to ensure that the valve material should be compatible with the process fluid, it is of an appropriate size with respect to flow rate, and that it should be within the required industry standards. The detailed knowledge of the different types of valves used in piping, and how each is actually used, will help an engineer and maintenance personnel to make the best choices.

The Bottom Line

Valves are very crucial in the safe and effective management of fluids in industrial piping systems. An understanding of the different types of valves that are used in pipework will help in identifying the correct design that is used in each instance be it to either provide isolation, control or direct flow. A thorough knowledge of valve functions, classifications, and piping valve symbols ensures precise installation and the long‑term reliability of the system.

Ashish Metals offers a wide variety of valves, such as forged globe valves, cast-steel gate valves, check valves, and so on. As a trusted valves supplier, Ashish Metals ensures that it adheres to the industry demands as well as offer the high quality and performance of valves that last longer in diverse piping needs. We have a wide range of available products that would suit your system needs. Browse our extensive product catalogue to find the valve that best fits your system

Frequently Asked Questions

Valves are mechanical devices that are implemented in a piping system to control, regulate, initiate, terminate, or redirect fluid flow and pressure in order to ensure safe and efficient operation of diverse industrial processes.

Valve is a device, which is utilized to control the flow and pressure of fluids in a pipe network. Common groupings include gate valves, globe valves, ball valves, check valves, butterfly valves, these types of valves are meant to carry out isolation functions, regulation functions or functions of controlling flow direction depending on application purpose.

At least four valved design allows a greater degree of control of the flow and also flexibility in the operation compared to two valved design, and is thus favored in processes that demand higher degree of accuracy and safety.

A three-lever valve uses three different levers for a valve to have multi-directional control of fluid flow in piping systems and wider options for manual operation of the valve.