Alloy 20

Fasteners

Tube Fittings

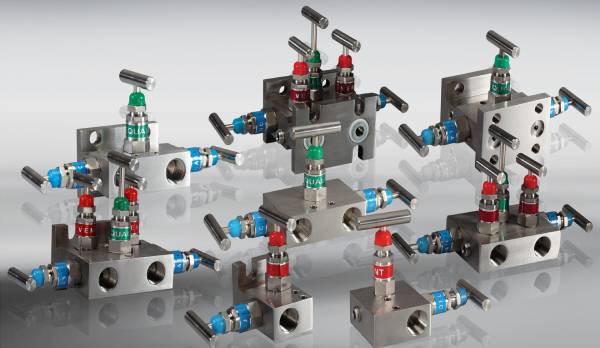

Manifold Valves

Ball Valves

Needle & Gauge Valve

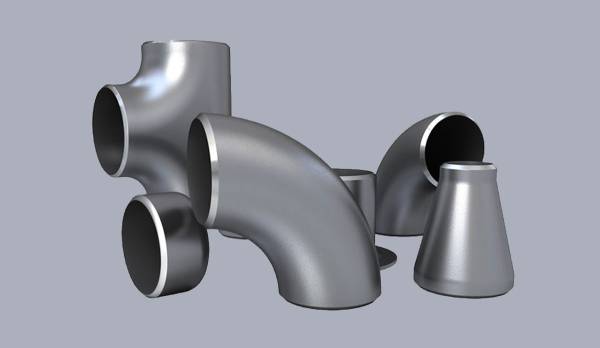

Pipe Fittings

- Alloy 20 Material Overview

- Alloy 20 Chemical and Mechanical Characteristics

- Alloy 20 Chemical Composition

- Alloy 20 Mechanical Properties

- Alloy 20 Product Forms and Coverage

- Why Alloy 20 Is Used Across Integrated Systems

- Alloy 20 Standards and Material Equivalents

- Why Choose Aashish Metal and Alloys for Alloy 20 Products

- Alloy 20 Supply and Procurement Capabilities

- Frequently Asked Questions About Alloy 20

Alloy 20 Material Overview

Alloy 20 is a nickel iron chromium alloy that has been developed to give dependable sulfuric acid and other hostile chemical resistance. The wide specification is used in applications where the traditional stainless steels are prone to localized corrosion, pitting and stress corrosion cracking.

Controlled chemical composition with added copper and molybdenum enables the Alloy 20 to provide constant corrosion resistance with consistent mechanical behavior. This balance renders the material appropriate in the production of industrial parts that are utilized in chemical processing, pharmaceutical production as well as acid handling systems.

Alloy 20 Chemical and Mechanical Characteristics

Alloy 20 is highly functioning in the corrosive service setting due to the optimized chemistry which facilitates resistance in both reducing and oxidizing conditions. The material withstands the structural integrity at pressures and temperatures that are likely to be experienced in process industries.

From a fabrication standpoint, Alloy 20 offers consistent weldability and formability. This allows it to be used across pressure-bearing components, piping connections, and instrumentation assemblies without compromising long-term service reliability.

Alloy 20 Chemical Composition

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 32.0 – 38.0 |

| Chromium (Cr) | 19.0 – 21.0 |

| Iron (Fe) | Balance |

| Molybdenum (Mo) | 2.0 – 3.0 |

| Copper (Cu) | 3.0 – 4.0 |

| Carbon (C) | ≤ 0.07 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

Note: Composition values are indicative and may vary based on product form and applicable standards.

Alloy 20 Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 551 MPa |

| Yield Strength (0.2%) | ≥ 241 MPa |

| Elongation | ≥ 30% |

| Hardness | ≤ 217 HB |

Note: Mechanical properties are indicative and may vary depending on product form, heat treatment, and applicable standards.

Alloy 20 Product Forms and Coverage

Alloy 20 is supplied in multiple product forms to support complete system design rather than isolated component selection. Based on application and service requirements, the material is commonly used in:

- Alloy 20 pipe for chemical transfer and process lines

- Alloy 20 plate and sheet for equipment fabrication

- Alloy 20 round bar for machined components

- Alloy 20 tubing for instrumentation and fluid control systems

- Alloy 20 fasteners for bolted assemblies

- Alloy 20 valves and pipe fittings for flow and connection control

This broad product coverage allows engineering teams to maintain material consistency across assemblies operating in corrosive service conditions.

Applications of Bimetal Products

Application Industry

Electrical and electronic components

Industrial machinery assemblies

Thermal and functional control components

Automotive and engineering systems

OEM and precision manufacturing

Why Alloy 20 Is Used Across Integrated Systems

Application of Alloy 20 in fasteners, fittings, valves and piping components assists in keeping all the materials compatible with each other in the system. This helps in decreasing chances of galvanic corrosion, eases material specification and enhances long term service durability in hostile environments.

In complicated installations with corrosive media, the specification of one alloy grade on a number of components also facilitates the same inspection planning, predictable maintenance operation, and uniform performance in the harsh working environment.

Alloy 20 Standards and Material Equivalents

Alloy 20 will be acceptable in the specifications of projects worldwide as it comes in many other international material names. It is typically known as UNS N08020 and is also cited as Alloy 20 CB3 or 20CB3 alloy in casting and specification documents.

Compliance, documentation, procurement alignment In most cases, equivalent material standards like DIN 2.4660 (as well as ASTM specifications like ASTM B473 and ASTM A351 CN7M) are used across regions and industries.

Why Choose Aashish Metal and Alloys for Alloy 20 Products

Aashish metal and alloys cater to the needs of the Alloy 20 products with a high emphasis on material compliance, application aptness, and the reliability of supply. We have designed our strategy in such a way that it addresses the demands of engineering and procurement teams that have to work in a corrosive service environment.

The products supplied by Aashish Metal and Alloys, which are alloys, are chosen and processed in order to fit the specifications of projects so as to be compatible across piping, instrumentation, and mechanical assemblies. Tight collaboration with buyers and technical is done to verify product form, specifications, and scope of inspection depending on operating conditions.

Alloy 20 Supply and Procurement Capabilities

| Parameter | Aashish Metal and Alloys |

|---|---|

| Material Grade | Alloy 20 (UNS N08020, Alloy 20 CB3) |

| Product Coverage | Pipes, fittings, valves, fasteners, tubing |

| Standards Compliance | ASTM, ASME, DIN, UNS |

| Manufacturing Forms | Wrought and cast products |

| Quality Documentation | Mill Test Certificates, inspection reports |

| Application Support | Specification and material selection guidance |

| Industries Served | Chemical, pharmaceutical, process industries |

| Supply Scope | Domestic and export project requirements |

Frequently Asked Questions About Alloy 20

Alloy 20 is used in chemical processing, pharmaceutical manufacturing, and acid handling systems where sulfuric acid resistance is required.

Yes. Alloy 20 was specifically developed to perform reliably in sulfuric acid environments across a wide concentration range.

Alloy 20 is designated as UNS N08020.

Yes. Alloy 20 is commonly specified across pipes, fittings, valves, and instrumentation components to maintain material consistency.

Alloy 20 provides improved resistance to sulfuric acid and stress corrosion cracking compared to many standard stainless steel grades.

While chemical processing is a primary use, Alloy 20 is also applied in pharmaceuticals, pollution control, and specialized industrial systems.

For More Information About Alloy 20 Products please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Materials

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- Thank You For Connecting

- Duplex and Super Duplex Steel Pipes and Tubes

- Duplex and Super Duplex Steel Threaded Fittings Manufacturer and Supplier

- Duplex Steel S31803 S32205 and Super Duplex S32750 S32760 Pipe Fittings

- Duplex S31803 S32205 Socket Weld Fittings Manufacturer

- Duplex and Super Duplex Steel Socket Weld Fittings

- Duplex and Super Duplex Steel Tube Fittings

- Stainless Steel 316 / 316L Pipes & Tubes

- Stainless Steel 321 Pipes & Tubes

- Inconel Pipes and Tubes

- Home uat

- Stainless Steel Pipe Fittings Manufacturer and Supplier

- Stainless Steel Pipes and Tubes

- C17200 Beryllium Copper

- C17300 Beryllium Copper

- C17500 Beryllium Copper

- BERYLLIUM COPPER STRIP & COIL

- Beryllium Copper C17200 Wire

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.