Stainless Steel 310 Needle Valve Manufacturer and Supplier

Home › Stainless Steel Products › Stainless Steel 310 Needle Valves

Aashish Metals is a trustworthy manufacturer and supplier of the Stainless Steel 310 Needle Valves which is intended to provide the precision of control, reliability, and safety in the circumstances of the high temperature and corrosiveness. These valves were manufactured using Alloy 310 (UNS S31000) according to ASTM A276 standards and are renowned to be of high strength, resistance to oxidation and high continuous service up to 2000 o F. All the SS 310 Needle Valves are manufactured into correct dimensions, smooth running of operation, and no leak connection so that they will have the same functionality in a tough industry like chemical processing, power generation, furnace, and refinery operations.

We have a complete range of pressure rating, end connections, and sizes of 310 Stainless Steel Needle Valves that are applicable to both instrumentation and industrial pipelines. High machining technology and high quality inspection processes ensures that the products are of high quality as per international standards. The presence of chromium and nickel in Alloy 310 increases the corrosion resistance and Stability in cyclic thermal conditions. Aashish Metals is a company that specializes in manufacturing reliable SS 310 valves, which can be used in the most adverse working conditions, hence it is a good alternative to engineers and procurement experts across the globe.

Stainless Steel 310 Gate Valves

Stainless Steel 310S Globe Valves

Stainless Steel 310 Ball Valves

SS 310 and 310S Needle Valves, ASTM A276 Stainless Steel 310S Instrumentation Valves, Alloy 310 Integral Bonnet Needle Valves, SS 310S Double Block and Bleed Valves, UNS S31000 Instrumentation Valves, DIN 1.4841 Stainless Steel 310S Globe and Gate Valves, SUS 310 Monoflange and Relief Valves, ASME SA276 310S Metering Valves, SS 310 Industrial and Manifold Valves Manufacturer in Mumbai India

Aashish Metals has a variety of Stainless Steel 310 and 310S Needle Valves which are utilized in flow control of high pressure and high temperature conditions. These valves are made of Alloy 310 (UNS S31000 and S31008) and are provided with high resistance to oxidation, scaling, and corrosion in continuous service up to 2000 o C. All valves are highly-engineered to have a strong-body, finable stem threads, and leak-free operation suitable in instrumentation, chemical and furnace systems.

Aashish Metals, being a major SS 310 S Valve Manufacturer in Mumbai, is supplying integral bonnet, double block and bleed, monoflange, and metering valves, which meet the standards of ASTM A276, ASME SA276 and DIN 1.4841. To match international industrial expectations of products, our products are tested on strength, durability and dimensional accuracy.

We also offer a wide selection of grades in different environment like Stainless Steel 316 Needle Valve and Stainless Steel 304L Needle Valve, it is providing a sure solution to all crucial applications.

- Stainless Steel 310 Needle Valves Specifications

- Stainless Steel 310 Needle Valves Equivalent Grades

- Stainless Steel 310 Needle Valves Quality and Test reports

- Related Types Of Stainless Steel 310 Needle Valves

- SS 310 Needle Valves Dimension

- SS 310 Female X Female Needle Valve Dimensions

- Dimensions Schedule SS 310 Male X Female Needle Valve

- 310 SS Male X Male Needle Valve Dimensions Chart

- Chemical Composition

- Mechanical Properties

- Stainless Steel 310 Needle Valves price list

- Why Choose Aashish Metals for Stainless Steel 310 Needle Valves

- Application Of SS 310 Needle Valves

UNS S31000 Integral Bonnet Needle Valve, 310 SS Forged Needle Valve, DIN 1.4841 Hydraulic Needle Valve, 310 SS High Pressure Needle Valve, SS 310 Union Bonnet Needle Valve, SS 310 Compression Needle Valve, 310 Stainless Steel Needle Control Valve, SS 310 Needle Valve Suppliers in Mumbai, India.

Contents of molybdenum and tungsten deliver the alloy resistance to moist decreasing media (e.g., sulfuric and hydrochloric acids). It need to now no longer be utilized in carrier temperatures above 1250° F because of the formation of adverse stages which shape above this temperature. It additionally has first rate resistance to oxidizing aqueous media. Stainless Steel WNR. 1.4841 Needle Valves has notable resistance to a huge sort of chemical method environments which include robust oxidizers consisting of ferric acids, acetic anhydride, and seawater and brine solutions. They are also generally used for chemical processing applications.

They are used for several applications consisting of in pharmaceutical industries use alloy and tubing to keep away from infection because of corrosion associated failures. They also are utilized in Chlorination systems, Pesticide production, Incineration scrubber systems, Waste water processing, and more. It became decided on for this software after significant trying out within the real bleach washing machine environment. It has higher corrosion resistance than the original material and higher than the following candidate. It is an alloy supposed for excessive temperature use in company of the right corrosion resistance. 310 Stainless Steel Needle Valves is machinable with the aid of using traditional strategies and are easily fashioned by means of having the aid of using traditional methods.

Stainless Steel 310 Needle Valve Specifications and Technical Details

| Property / Standard | Details |

|---|---|

| Size | 1/4″ to 1″ (Female / Female BSP and BSPT), 3/8″ to 1″ (Female / Female NPT) and 1/4″ to 1/2″ (Male / Female BSPP). |

| Thread | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| Connection | Threaded, Tube End, Butt Weld, Socket Weld, Weld Nipple, Flanged, Sae |

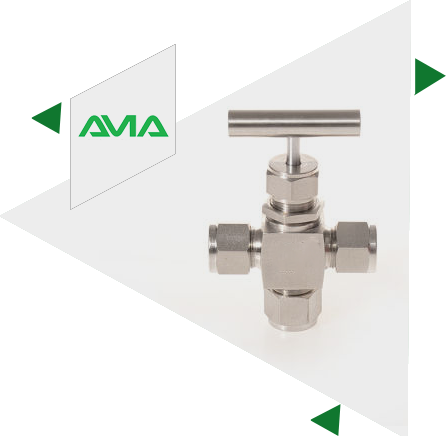

| Function | 2 Way, 3 Way |

| Pressure Rating | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI, 15,000 PSI, 20000 PSI |

| Orifice Size | 2 MM TO 9.5 MM |

| Standard | ISO , DIN , ANSI , API , ASME , AWWA , MSS |

| Design | Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design |

| Patterns | Straight / Angle |

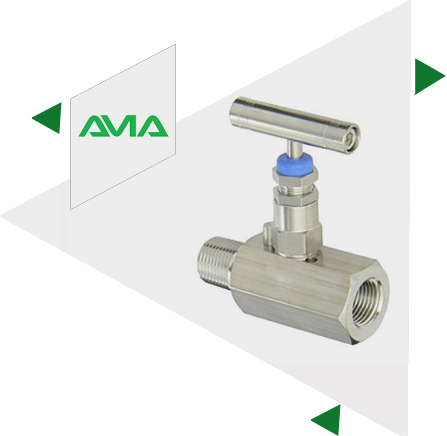

| Needle Valve Type | Bar Stock Needle Valve, High Pressure Needle Valve, Angle Needle Valve, Union Bonnet High Pressure Female X-Female NPT, Miniature Needle Valve, Screwed Bonnet Needle Valve, Forged Needle Valve |

| Maximum Working Pressure | Up to 6000 psig (413 bar) |

| Equivalent Brands | Swagelok, Parker, Dk-Lok, Hamlet, Oliver Valves, Hoke |

Stainless Steel 310 Needle Valves Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | – | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | – | X8CrNi25-21 |

Stainless Steel 310 Needle Valves Chemical Properties

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 – 26.00 | 0.10 max | 19.00 – 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 | 0.75 max | 19.00 – 21.00 | 53.095 min |

Stainless Steel 310 Needle Valves Quality and Test reports

- Third Party Inspection

- Radiography Test

- Hydrostatic Shell Test

- Pneumatic Seat Test

- Pitting Resistance Test

- Hydrostatic Test

We Supplied a Comprehensive Range Of 310 Stainless Steel Needle Valves

Related Types Of Stainless Steel 310 Needle Valves

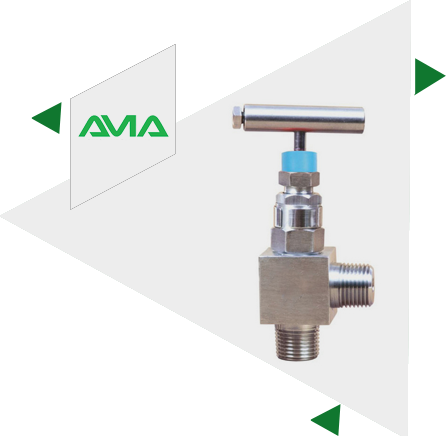

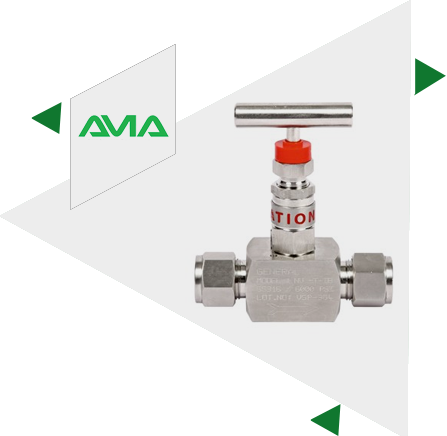

SS 310 Angle Needle Valve

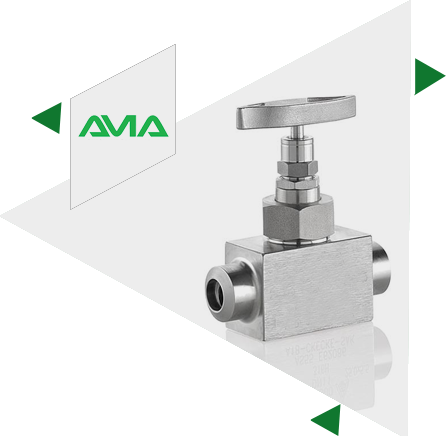

SS 310 Union Bonnet Needle Valve

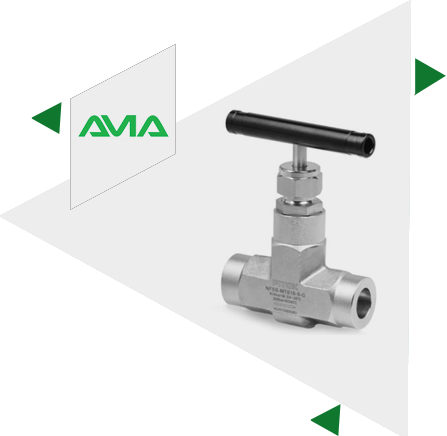

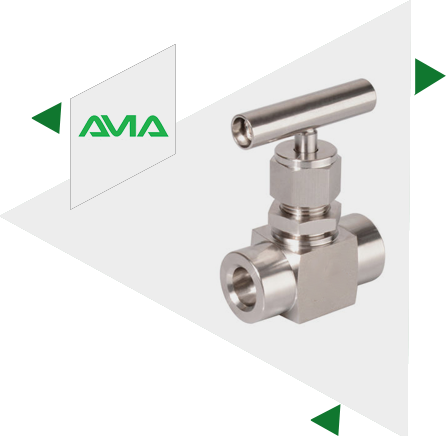

SS 310 Forged Needle Valve

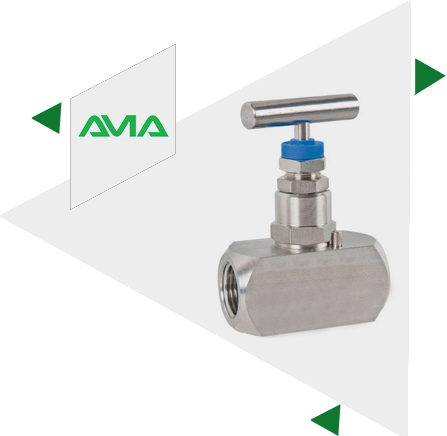

SS 310 Screwed End Needle Valve

SS 310 Tube End Needle Valve

SS 310 Socket Weld Needle Valve

SS 310 Hex Body Needle Valve

SS 310 3 Way Needle Valve

SS 310 Panel Mounted Needle Valve

SS 310 Miniature Needle Valve

SS 310 Round Body Needle Valve

SS 310 Square Body Needle Valve

Available Stock and Types of Stainless Steel SS 310 and 310S Instrumentation Valves

| Stainless Steel 310S Ball Valve | Stainless Steel 310 Monoflange Valves |

| Stainless Steel 310 Panel Mounted Needle Valve | Stainless Steel 310H Instrumentation Non Return Valve |

| SS 310S Hydraulic Ball Valve | SS 310 Instrumentation Needle Valve |

| SS 310 Forged Integral Bonnet Angle Type Needle Valves | SS 310H 3 Way Needle Valve |

| Stainless Steel 310S Valves | Stainless Steel 310H Forged Steel Valves |

| Stainless Steel 310H Mini Needle Valve | SS 310H Manifold Valves |

| Stainless Steel 310 4 Way Ball Valve | Stainless Steel 310S Panel Mounted Ball Valve |

| Stainless Steel 310H Threaded Butterfly Valves | SS 310S Instrumentation Check Valve |

| SS 310 Integral-Bonnet Needle Valves | Stainless Steel 310S Block Bleed Valve |

| Stainless Steel 310H Valves | SS 310H High Pressure Ball Valves |

| Type SS 310H Industrial Valves | SS 310 Manifold Check Valve |

| Stainless Steel 310 Valves | Stainless Steel 310S Pannel Mounting Ball Valve |

| Stainless Steel 310 High Pressure Needle Valve | Stainless Steel 310S NRV Check Valve |

| SS 310H Female X Female Check Valve | SS 310 Panel Mounted Ball Valve |

| Stainless Steel 310S Instrumentation Ball Valves | Stainless Steel 310H 5 Way Manifold Valve |

| Stainless Steel 310 Instrumentation Check Valve | Stainless Steel 310S 2 Way Ball Valves |

| Stainless Steel 310S Non Return Valve | Stainless Steel 310H High Pressure Ball Valve |

| Stainless Steel 310S 3 PCS Ball Valve | Austenitic Stainless Steel 310H Valves |

| SS 310 3-way Flange Ball Valves | Stainless Steel 310S Valves |

| SS 310H Instrument Solenoid Valve | Stainless Steel 310 Double Block & Bleed Valves |

| Stainless Steel 310S Monoflange Manifold Valves | SS 310 Manifold Check Valve |

| Stainless Steel 310S Forged-Body Needle Valves | Stainless Steel 310H Pressure Reducing Valve |

| Stainless Steel 310 Hydraulic Ball Valve | Stainless Steel 310 Ball Valve Threaded |

| SS 310S Bleed and Purge Valves |

SS 310 Needle Valves Dimensions

| Size | L | a | b | W | H |

|---|---|---|---|---|---|

| 1/8″ | 56 | 28 | 28 | 60 | 80 |

| ¼” | 56 | 28 | 28 | 60 | 80 |

| 3/8” | 56 | 28 | 28 | 60 | 80 |

| ½” | 58 | 28 | 28 | 60 | 81 |

| ¾” | 62 | 35 | 35 | 60 | 85 |

| 1” | 70 | 45 | 45 | 70 | 100 |

| Port Size (BSP) | Media Pressure | Media Temperature | CV |

|---|---|---|---|

| 1/8″ | 0 to 408 Bar | -20°C to 230°C | |

| ¼” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| 3/8” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| ½” | 0 to 408 Bar | -20°C to 230°C | 0.6 |

| ¾” | 0 to 408 Bar | -20°C to 230°C | 1.6 |

| 1” | 0 to 408 Bar | -20°C to 230°C | 2.5 |

Female X Female Needle Valve Dimensions

| Size | A | B | ±C | D |

|---|---|---|---|---|

| 1/8″ | 19 | 50 | 65 | 45 |

| 1/4″ | 22 | 50 | 70 | 50 |

| 3/8″ | 25 | 55 | 75 | 55 |

| 1/2″ | 30 | 65 | 85 | 55 |

| 3/4″ | 36 | 75 | 95 | 65 |

| 1″ | 40 | 85 | 100 | 65 |

| 1-1/4″ | 54 | 90 | 120 | 80 |

| 1-1/2″ | 62 | 110 | 130 | 88 |

| 2 | 72 | 120 | 150 | 95 |

Dimensions Schedule Male X Female Needle Valve

| Size | A | B | ±C | D |

|---|---|---|---|---|

| 1/8″ | 19 | 50 | 65 | 45 |

| 1/4″ | 22 | 50 | 70 | 50 |

| 3/8″ | 25 | 55 | 75 | 55 |

| 1/2″ | 30 | 65 | 85 | 55 |

| 3/4″ | 36 | 75 | 95 | 65 |

| 1″ | 40 | 85 | 100 | 65 |

| 1-1/4″ | 54 | 90 | 120 | 80 |

| 1-1/2″ | 62 | 110 | 130 | 88 |

| 2 | 72 | 120 | 150 | 95 |

Male X Male Needle Valve Dimensions Chart

| Size | A | B | ±C | D |

|---|---|---|---|---|

| 1/8″ | 19 | 50 | 65 | 45 |

| 1/4″ | 22 | 50 | 70 | 50 |

| 3/8″ | 25 | 55 | 75 | 55 |

| 1/2″ | 30 | 65 | 85 | 55 |

| 3/4″ | 36 | 75 | 95 | 65 |

| 1″ | 40 | 85 | 100 | 65 |

| 1-1/4″ | 54 | 90 | 120 | 80 |

| 1-1/2″ | 62 | 110 | 130 | 88 |

| 2 | 72 | 120 | 150 | 95 |

We Keep Bulk Stock Of 310 Stainless Steel Needle Valves At Our Stockyard, Contact Us For Free Sample & Stock List.

Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

Related Product

- Stainless Steel 304 Needle Valve

- Stainless Steel 317L Needle Valve

- Stainless Steel 304L Needle Valve

- Stainless Steel 321 Needle Valve

- Stainless Steel 316 Needle Valve

- Stainless Steel 347H Needle Valve

- Stainless Steel 316L Needle Valve

- Stainless Steel 904L Needle Valve

- Stainless Steel 316Ti Needle Valve

- SMO 254 Needle Valve

Stainless Steel 310 Needle Valves price list

Request the latest Stainless Steel 310 Needle Valves List. Please click on the request a quote button or click here to request the updated price list and ready stock information along with your requirement. Aashish Metal & Alloys maintains a stock of all standard items and can export them at best price for 310 Stainless Steel Needle Valves.

Why Choose Aashish Metals for Stainless Steel 310 Needle Valves

Aashish Metals is a reputable company that manufactures and supplies Stainless Steel 310 Needle Valves with high precision engineering, superior quality, and is also reliable in operation in critical processes. The valves are all made of Alloy 310 (UNS S31000) and 310S (UNS S31008) material grades which provide high-resistance to oxidation, scaling, and corrosion at high temperatures. We are manufactured to ASTM A276 and ASME SA276 standards, so we are both dimensional and long-lasting.

We make use of the latest machining technology, stringent testing, and quality checks that have served to ensure product reliability in harsh conditions like chemical processing, power generation and instrumentation systems. Having years of experience and a deep belief in the importance of delivering products on time, Aashish Metals offers to its customers high-performance SS 310 Needle Valves that became durable, efficient, and safe. We are the best solution to the needs of stainless-steel valves throughout the world due to our experience, international quality standards, and the attentive service to the customer.

Application Of SS 310 Needle Valves

Application Industry

For More Information About Stainless Steel 310 Needle Valves please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Frequently Asked Questions on Stainless Steel 310 Needle Valves

Aashish Metals is an Indian based company that manufactures Stainless Steel 310 Needle Valves as one of the largest manufacturers of perforated engineered valves as per ASTM A276 and ASME SA276 standards in the industrial and instrumentation industries.

The SS 310 Needle Valves are available in 1 inch (25mm) and 3/4 inch (6mm) size, which can be used in high pressure systems and low pressure systems. They may also be made in bespoke sizes to meet application requirements of a project.

Alloy 310 Needle Valves can resist temperatures to 2000°F (1093 °C), and it is the best solution in furnaces, heat exchangers, and high-temperature processing units.

The Stainless Steel 310 Needle Valves have male-female threaded, compression and socket-weld end connections to make sure that they are easy to install and provide a leak-free operation.

The stainless steel 310 needle valves are mostly used in chemical processing, oil and gas, power generation, and instrumentation systems.

Yes. Compared to SS 310, SS 310S Needle Valves are less carbon-filled and hence are more weldable with reduced carbide precipitation that occurs in high-temperature service.

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.