Stainless Steel 304L Needle Valve Manufacturer and Supplier

Home › Stainless Steel Products › Stainless Steel 304L Needle Valves

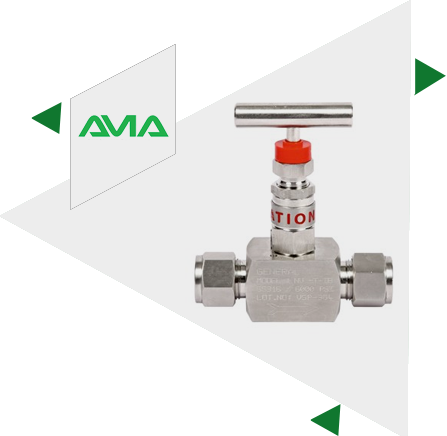

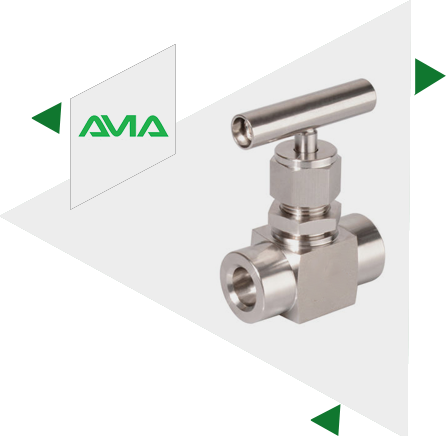

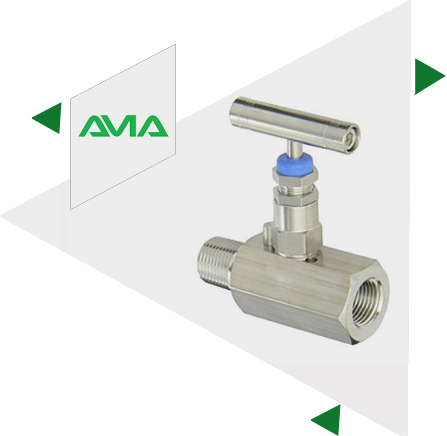

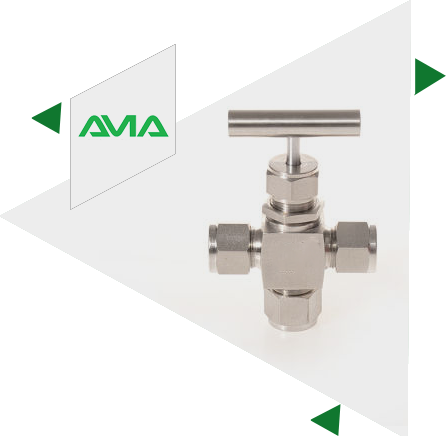

Aashish Metals is a reliable producer and distributor of Stainless Steel 304L Needle Valves that are able to be utilized in the accurate regulation of flow in instrumentation and hydraulic systems. These valves are made of low-carbon SS 304L as per ASTM A182 and A276 standards, which provides them with a lot of resistance to corrosion, good welding and strength in the demanding industrial conditions. All SS 304L needle valves are specifically designed to be durable and work reliably in chemical, oil and gas, and process industries. Our ASTM A182 F304L needle valves will be leak free due to the use of MTR approved material and quality inspection to guarantee the product will not leak when under high pressure. Select Premium 304L stainless steel needle valves of Aashish Metals which provide steady performance and extended service.

SS 310S Check Valves

SS 310S Butterfly valve

Steel 310S Ball Valves

Our SS 304L Instrumentation Ball Valve, Check Valve and Needle Valve will be engineered with low-carbon stainless steel (304L) to ensure stability in the flow control and resistance to corrosion. These 304L instrumentation valves comply with ASTM A182 and A276 and are used to provide leak-free performance and life in both chemical and hydraulic and process monitoring.

SS 304L Instrumentation Double Block and Bleed Valves, Grade 304L Stainless Steel Instrumentation Ball Valves, 304L Instrumentation Piston Check Valves, SS 304L Instrument Valve Fittings, ASTM A276 Type 304L Instrumentation Needle Valves, UNS S30403 High Pressure Instrumentation Valves, Stainless Steel 304L Instrument Valve Exporter and Stockist in India

The product that Aashish Metals produces and supplies is SS 304L Instrumentation Valves of a complete variety which is designed to control the flow accurately and reliably in high-pressure and corrosive environments. We have Double Block and Bleed Valves, Ball Valves, Piston Check Valves and Instrumentation Needle Valves which are made of low-carbon Stainless Steel 304L. All the valves manufactured are ASTM A276 and A182 compliant and are to the UNS S30403 and DIN 1.4306 / 1.4307 standards.

These 304L Instrumentation Valves are reliable to be shut-off, leak free and have the best corrosion resistance abilities thus able to be used in chemical processing, oil and gas, petrochemical and instrumentation pipelines. The SS 304L Instrumentation Ball Valves and Needle Valves allow free functioning in high pressure, and the Piston Check Valves avoid the backflow and preserve the integrity of the system. Another category of our extensive Stainless Steel Products is the provision of 304L Instrumentation Valve Fittings that not only provide connections that are secure and free of vibration.

Being a reliable Stainless Steel 304L Instrumentation Valve Exporter and Stockist in India, Aashish Metals provides the MTR approved valves that are consistent in quality, dimensions, and life span. Discover similar Stainless Steel 304 Needle Valves to find more grades and technical specifications.

- Stainless Steel 304 and 304L Needle Valve Material Specification Chart

- Equivalent Grades of Stainless Steel 304 and 304L Needle Valves

- Stainless Steel 304L Needle Valves Quality and Test reports

- Related Types Of Stainless Steel 304L Needle Valves

- Dimensions of Class 150LB Stainless Steel 304L Ball Valves

- 304L Stainless Steel Class 300 Ball Valve Dimension Chart

- Dimension Standards for SS 304L Class 600 Ball Valves

- Dimensions Chart of SS 304 and 304L Female Thread Needle Valves

- Chemical Composition

- Mechanical Properties

- Stainless Steel 304L Needle Valves price list

- We supply of variety SS 304L Needle Valves

- Application Of SS 304L Needle Valves

UNS S30403 Integral Bonnet Needle Valve, 304L SS Forged Needle Valve, SS 304L Compression Needle Valve, DIN 1.4306 Hydraulic Needle Valve, 304L SS High Pressure Needle Valve, 304L Stainless Steel Needle Control Valve, SS 304L Union Bonnet Needle Valve, SS 304L Needle Valve Suppliers in Mumbai, India.

They also are utilized in Complex Acid Mixtures, Electro-Galvanizing Rolls, Expansion Bellows, Flue Gas Scrubber Systems, Geothermal Wells, HF Furnace Scrubbers, etc. They are as properly utilized in Incineration Scrubber Systems, Nuclear Fuel Reprocessing, Pesticide Production, Phosphoric Acid Production, etc. Stainless Steel WNR 1.4306 Needle Valves are regularly utilized in Pickling Systems, Plate Heat Exchangers, Selective Leaching SystemsSO2 Cooling Towers, Sulfonation Systems, Tubular Heat Exchangers, Weld Overlay-Valves, and so on. Meanwhile, wrought types of this alloy are provided within the answer heat-handled situation until in any other case specified. The excessive chromium content material gives excellent resistance to oxidizing media whilst the molybdenum and tungsten content material provide excellent resistance to decreasing media.

It has incredible resistance to oxidizing aqueous media inclusive of moist chlorine and combos containing nitric acid or oxidizing acids with chlorine ions. It resists the formation of grain-boundary precipitates within the weld heat-affected zone, as a result making it appropriate for maximum chemical technique applications within the as-welded situation. 304L Stainless Steel Needle Valves gives most advantageous resistance to environments in which decreasing and oxidizing situations are encountered in technique streams. It’s a maximum flexible nickel-chromium-molybdenum-tungsten alloy to be had these by means of having an advanced resistance to each uniform and localized corrosion in addition to quite a few combined commercial chemicals.

Stainless Steel 304 and 304L Needle Valve Material Specification Chart

| Property / Standard | Details |

|---|---|

| Size | 1/4″ to 1″ (Female / Female BSP and BSPT), 3/8″ to 1″ (Female / Female NPT) and 1/4″ to 1/2″ (Male / Female BSPP). |

| Thread | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| Connection | Threaded, Tube End, Butt Weld, Socket Weld, Weld Nipple, Flanged, Sae |

| Function | 2 Way, 3 Way |

| Pressure Rating | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI, 15,000 PSI, 20000 PSI |

| Orifice Size | 2 MM TO 9.5 MM |

| Standard | ISO , DIN , ANSI , API , ASME , AWWA , MSS |

| Design | Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design |

| Patterns | Straight / Angle |

| Needle Valve Type | Bar Stock Needle Valve, High Pressure Needle Valve, Angle Needle Valve, Union Bonnet High Pressure Female X-Female NPT, Miniature Needle Valve, Screwed Bonnet Needle Valve, Forged Needle Valve |

| Maximum Working Pressure | Up to 6000 psig (413 bar) |

| Equivalent Brands | Swagelok, Parker, Dk-Lok, Hamlet, Oliver Valves, Hoke |

Equivalent Grades of Stainless Steel 304 and 304L Needle Valves

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

Available Stock and Types of Stainless Steel 304L Instrumentation Valves

| Stainless Steel 304L Floating Ball Valves | Grade 304L Stainless Steel Segmented Ball Valves |

| SS 304L Trunnion Mounted Ball Valves | UNS S30403 Top Entry Ball Valves |

| Stainless Steel 304L 1 Piece Ball Valves | 304L SS 2 Piece Ball Valves Dealer |

| Stainless Steel 304L 3 Piece Ball Valves | 304L SS Actuated Ball Valves in Mumbai |

| Stainless Steel 304L Sanitary Ball Valves | Stainless steel 304L Ball Valve 2 – pc HP |

| 304L Stainless Steel Ball Valve 2 – pc | DIN 1.4306 / 1.4307 Socket Weld Ball Valve Exporter |

| Stainless Steel 304L Split-Body Ball Valve | Stainless Steel 304L 4 Way Ball Valves |

| Stainless Steel 304L Single-piece Ball Valve | Stainless Steel 304L Two-piece Ball Valves |

| SS 304L Three-piece Ball Valve in India | Stainless Steel 304L Inline Mini Ball Valve |

| SS UNS S30403 Threaded Ball Valve | 304L Stainless Steel Industrial Ball Valves |

| SS 304L Pneumatic Actuated Ball Valves | Steel DIN 1.4307 High Pressure 2 Way Ball Valve |

| Stainless Steel 304L Double Union Ball Valves | 304L Stainless Steel Forged Ball Valve |

| Stainless Steel 304L Hydraulic Ball Valve | SS 304L Compression Ball Valves Supplier |

| Stainless Steel 304L Ball Valve 2 piece | Stainless Steel 304L Five-Way Ball Valves |

Stainless Steel 304L Needle Valves Quality and Test reports

- Third Party Inspection

- Radiography Test

- Hydrostatic Shell Test

- Pneumatic Seat Test

- Pitting Resistance Test

- Hydrostatic Test

We Supplied a Comprehensive Range Of 304L Stainless Steel Needle Valves

Related Types Of Stainless Steel 304L Needle Valves

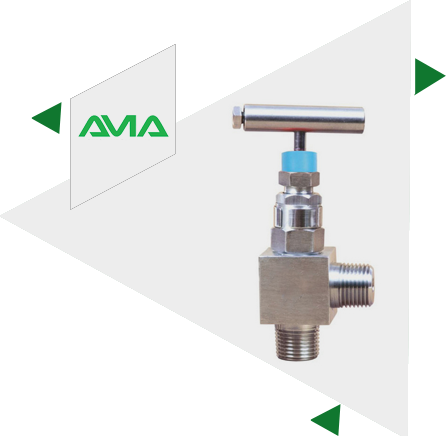

SS 304L Angle Needle Valve

SS 304L Union Bonnet Needle Valve

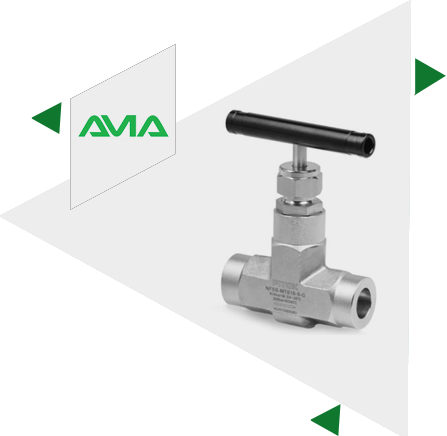

SS 304L Forged Needle Valve

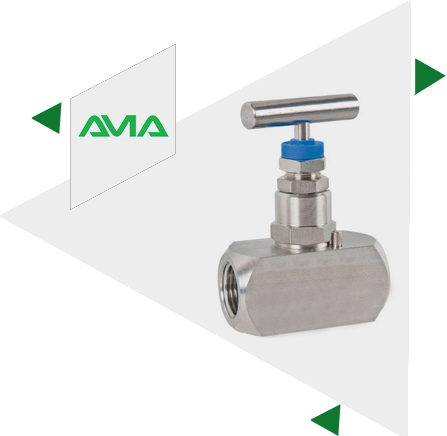

SS 304L Screwed End Needle Valve

SS 304L Tube End Needle Valve

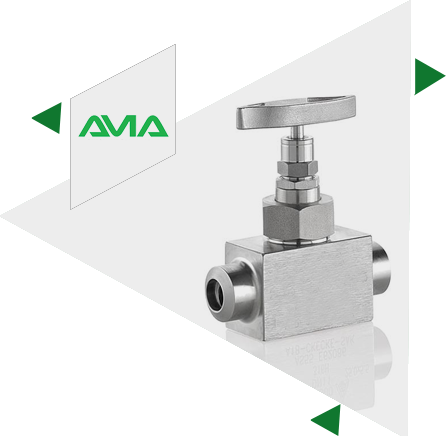

SS 304L Socket Weld Needle Valve

SS 304L Hex Body Needle Valve

SS 304L 3 Way Needle Valve

SS 304L Panel Mounted Needle Valve

SS 304L Miniature Needle Valve

SS 304L Round Body Needle Valve

SS 304L Square Body Needle Valve

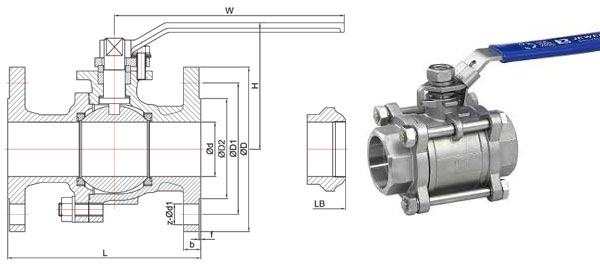

Dimensions of Class 150LB Stainless Steel 304L Ball Valves

| Main Dimensions (mm) | Weight (kgs) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | L | LB | ∮d | ∮D | ∮D1 | ∮D2 | b | f | z-∮d1 | H | W | RF | BW |

| 1/2″ | 108 | 140 | 13 | 90 | 60.3 | 35 | 9.6 | 2 | 4-16 | 55 | 130 | 2.3 | 1.8 |

| 3/4″ | 117 | 152 | 19 | 100 | 69.9 | 43 | 11.2 | 2 | 4-16 | 55 | 130 | 3.0 | 2.8 |

| 1″ | 127 | 165 | 25 | 110 | 79.4 | 51 | 12.7 | 2 | 4-16 | 70 | 160 | 4.5 | 3.7 |

| 1-1/2″ | 165 | 190 | 38 | 125 | 98.4 | 73 | 15.9 | 2 | 4-16 | 90 | 200 | 7.0 | 6.5 |

| 2″ | 178 | 216 | 49 | 150 | 120.7 | 92 | 17.5 | 2 | 4-19 | 105 | 350 | 9.5 | 8.5 |

| 2-1/2″ | 190 | 241 | 62 | 180 | 139.7 | 105 | 20.7 | 2 | 4-19 | 155 | 400 | 15 | 14 |

| 3″ | 203 | 283 | 74 | 190 | 152.4 | 127 | 22.3 | 2 | 4-19 | 165 | 500 | 19 | 21 |

| 4″ | 229 | 305 | 100 | 230 | 190.5 | 157 | 22.3 | 2 | 8-19 | 205 | 500 | 33 | 35 |

| 6″ | 394 | 457 | 150 | 280 | 241.3 | 216 | 23.9 | 2 | 8-22 | 255 | 600 | 93 | 98 |

| 8″ | 457 | 521 | 201 | 345 | 298.5 | 270 | 27.0 | 2 | 8-22 | 280 | 800 | 160 | 170 |

| 10″ | 533 | 559 | 252 | 405 | 362.0 | 324 | 28.6 | 2 | 12-25 | 345 | 800 | 200 | 225 |

| 12″ | 610 | 635 | 303 | 485 | 431.8 | 381 | 30.2 | 2 | 12-25 | 420 | 800 | 280 | 295 |

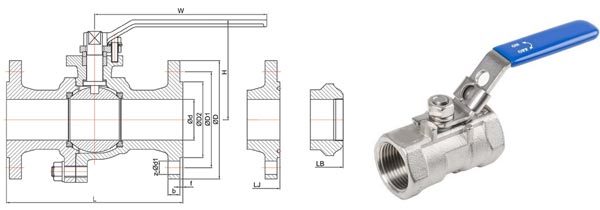

304L Stainless Steel Class 300 Ball Valve Dimension Chart

| ANSI 300 LB | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Dimensions (mm) | Weight (kgs) | ||||||||||||

| NPS | L | LB | ∮d | ∮D | ∮D1 | ∮D2 | b | f | z-∮d1 | H | W | RF | BW |

| 1/2″ | 140 | 140 | 13 | 95 | 66.7 | 35 | 12.7 | 2 | 4-16 | 55 | 130 | 2.5 | 1.8 |

| 3/4″ | 152 | 152 | 19 | 115 | 82.6 | 43 | 14.3 | 2 | 4-16 | 55 | 130 | 3.5 | 2.0 |

| 1″ | 165 | 165 | 25 | 125 | 88.9 | 51 | 15.9 | 2 | 4-16 | 70 | 160 | 5.5 | 3.2 |

| 1-1/2″ | 190 | 190 | 38 | 155 | 114.3 | 73 | 19.1 | 2 | 4-22 | 90 | 200 | 10.5 | 5.5 |

| 2″ | 216 | 216 | 49 | 165 | 127.0 | 92 | 20.7 | 2 | 8-19 | 105 | 350 | 14.5 | 8.7 |

| 2-1/2″ | 241 | 241 | 62 | 190 | 149.2 | 105 | 23.9 | 2 | 8-22 | 153 | 400 | 23.5 | 15 |

| 3″ | 283 | 283 | 74 | 210 | 168.3 | 127 | 27.0 | 2 | 8-22 | 165 | 500 | 30 | 18 |

| 4″ | 305 | 305 | 100 | 255 | 200.0 | 157 | 30.2 | 2 | 8-22 | 205 | 500 | 55 | 36 |

| 6″ | 403 | 457 | 150 | 320 | 269.9 | 216 | 35.0 | 2 | 12-22 | 255 | 600 | 118 | 85 |

| 8″ | 502 | 521 | 201 | 380 | 330.2 | 270 | 39.7 | 2 | 12-25 | 280 | 800 | 200 | 152 |

| 10″ | 508 | 559 | 252 | 445 | 387.4 | 324 | 46.1 | 2 | 16-28 | 345 | 800 | 250 | 105 |

| 12″ | 648 | 635 | 303 | 520 | 450.8 | 381 | 49.3 | 2 | 16-32 | 420 | 800 | 330 | 232 |

Dimension Standards for SS 304L Class 600 Ball Valves

| Main Dimensions (mm) | Weight (kgs) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | L/LB | LJ | ∮d | ∮D | ∮D1 | ∮D2 | b | f | z-∮d1 | H | W | RF | BW |

| 1/2″ | 165 | – | 13 | 95 | 66.7 | 35 | 14.3 | 6.4 | 4-16 | 62 | 130 | 3.3 | 2.6 |

| 3/4″ | 190 | – | 19 | 115 | 82.6 | 43 | 15.9 | 6.4 | 4-19 | 62 | 160 | 4.5 | 3.1 |

| 1″ | 216 | – | 25 | 125 | 88.9 | 51 | 17.5 | 6.4 | 4-19 | 78 | 200 | 7.2 | 4.8 |

| 1-1/2″ | 241 | – | 38 | 155 | 114.3 | 73 | 22.3 | 6.4 | 4-22 | 100 | 350 | 13.5 | 8.0 |

| 2″ | 292 | 295 | 49 | 165 | 127.0 | 92 | 25.4 | 6.4 | 8-19 | 120 | 400 | 19 | 13 |

| 2-1/2″ | 330 | 333 | 62 | 190 | 149.2 | 105 | 28.6 | 6.4 | 8-22 | 175 | 500 | 31 | 22 |

| 3″ | 356 | 359 | 74 | 210 | 168.3 | 127 | 31.8 | 6.4 | 8-22 | 212 | 600 | 39 | 27 |

| 4″ | 432 | 435 | 100 | 275 | 215.9 | 157 | 38.1 | 6.4 | 8-25 | 235 | 600 | 71 | 53 |

| 6″ | 559 | 62 | 150 | 322 | 292.1 | 216 | 47.7 | 6.4 | 12-29 | 290 | 800 | 153 | 120 |

Have any questions or requirements?

Dimensions Chart of SS 304 and 304L Female Thread Needle Valves

| Connection | Type and Size | Orifice | Cv | Dimension, | in.(mm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | in.(mm) | L1 | L2 | C | D | E | F | H | |

| 1/8 Female NPT | 1/8 Female NPT | 0.12 (3.0) | 0.20 | 0.81 (21.6) | 0.81 (21.6) | 0.39 (10.0) | 2.50 (63.5) | 0.44 (11.2) | 0.53 (13.5) | 2.50 (63.5) |

| 1/4 Female NPT | 1/4 Female NPT | 0.16 (4.0) | 0.35 | 1.06 (27.0) | 1.06 (27.0) | 0.50 (12.7) | 2.97 (75.5) | 0.50 (12.7) | 0.78 (19.8) | 2.97 (75.5) |

| 3/8 Female NPT | 3/8 Female NPT | 0.2 (5.1) | 0.56 | 1.06 (27.0) | 1.06 (27.0) | 0.50 (12.7) | 2.97 (75.5) | 0.50 (12.7) | 0.78 (19.8) | 2.97 (75.5) |

| 1/2 Female NPT | 1/2 Female NPT | 0.25 (6.4) | 0.70 | 1.50 (38.1) | 1.50 (38.1) | 0.75 (19.1) | 3.91 (93.3) | 0.75 (19.1) | 1.03 (26.2) | 3.91 (93.3) |

| 3/4 Female NPT | 3/4 Female NPT | 0.29 (7.5) | 0.95 | 1.63 (41.3) | 1.63 (41.3) | 0.75 (19.1) | 3.91 (93.3) | 0.75 (19.1) | 1.03 (26.2) | 3.91 (93.3) |

| 1/8 Male NPT | 1/8 Male NPT | 0.08 (3.0) | 0.20 | 0.81 (21.6) | 0.81 (21.6) | 0.39 (10.0) | 2.50 (63.5) | 0.44 (11.2) | 0.53 (13.5) | 2.50 (63.5) |

| 1/4 Male NPT | 1/4 Male NPT | 0.16 (4.0) | 0.35 | 0.98 (25.0) | 0.98 (25.0) | 0.39 (10.0) | 2.50 (63.5) | 0.44 (11.2) | 0.53 (13.5) | 2.50 (63.5) |

| 3/8 Male NPT | 3/8 Male NPT | 0.2 (5.1) | 0.56 | 1.12 (28.4) | 1.12 (28.4) | 0.50 (12.7) | 2.97 (75.5) | 0.50 (12.7) | 0.78 (19.8) | 2.97 (75.5) |

| 1/2 Male NPT | 1/2 Male NPT | 0.25 (6.4) | 0.70 | 1.50 (38.1) | 1.50 (38.1) | 0.50 (12.7) | 2.97 (75.5) | 0.50 (12.7) | 0.78 (19.8) | 2.97 (75.5) |

| 3/4 Male NPT | 3/4 Male NPT | 0.29 (7.5) | 0.95 | 1.63 (41.3) | 1.63 (41.3) | 0.75 (19.1) | 3.91 (93.3) | 0.75 (19.1) | 1.03 (26.2) | 3.91 (93.3) |

We Keep Bulk Stock Of 304L Stainless Steel Needle Valves At Our Stockyard, Contact Us For Free Sample & Stock List.

Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| SS 304L | 0.35 max | 2 max | 1.00 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 13 | – |

Mechanical Properties

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| 304L | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Related Products

- Stainless Steel 304 Needle Valve

- Stainless Steel 317L Needle Valve

- Stainless Steel 310 Needle Valve

- Stainless Steel 321 Needle Valve

- Stainless Steel 316 Needle Valve

- Stainless Steel 347H Needle Valve

- Stainless Steel 316L Needle Valve

- Stainless Steel 904L Needle Valve

- Stainless Steel 316Ti Needle Valve

- SMO 254 Needle Valve

Test Certificates for Stainless Steel 304 and 304L Needle Valves

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Uses and Applications of Stainless Steel 304 and 304L Needle Valves

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment

Stainless Steel 304L Needle Valves price list

Request the latest Stainless Steel 304L Needle Valves List. Please click on the request a quote button or click here to request the updated price list and ready stock information along with your requirement. Aashish Metal & Alloys maintains a stock of all standard items and can export them at best price for 304L Stainless Steel Needle Valves.

We supply of variety SS 304L Needle Valves

Aashish Metal & Alloys is a Highly Acclaimed Manufacturer & suppliers of Stainless Steel 304L Needle Valves offering all varieties in all types of 304L Stainless Steel in all sizes, with more then 52 countries worldwide.

| 304L Stainless Steel Tube End Needle Valve | SS 304L Socket Weld Needle Valve |

| Stainless Steel 304L Male Needle Valve | Stainless 304L Body Needle Valves |

| Stainless Steel 304L Pneumatic Needle Valve | Stainless 304L TMulti-Port & Gauge Needle valve |

| NPT Thread Stainless Steel 304L Needle Valve | Stainless Steel 304L Flow Control Needle Valves |

| UNS S30403 Flanged Needle Valves | Stainless Steel 304L Needle Control Valve |

| Stainless Steel 304L Water Flow Control Needle Valve | 304L SS High Temperature Needle Valve |

| SS 304L Integral Bonnet Needle Valve Suppliers | 1/4 Stainless Steel 304L Needle Valve |

| SS 304L Compression Needle Valve Dealer | SS 304L Hydraulic Needle Valve Exporter |

| 304L SS Miniature Needle Valve Stockholder | SS 304L Forged Needle Valve Distributors |

| SS 304L Hex Needle Valve | 304L Stainless Steel Panel Mount Needle Valve |

| UNS S30403 Union Bonnet Needle Valve | SS 304L Screwed End Needle Valve Manufacturer |

| 304L SS 3000 PSI Instrumentation Needle Valve | SS 304L 6000 PSI Needle Valve |

| SS 304L Female Thread Needle Valve | Stainless Steel 304L Angle Needle Valve |

| 304L SS 3 Way Needle Valve | 304L SS Panel Mounted Needle Valve |

| DIN 1.4307 Needle Valve | 1½” Stainless Steel 304L Square Body Needle Valve |

| Stainless Steel 304L Needle Valves | SS 304L Instrumentation Needle Valve |

| 304L SS Female Thread Needle Valve | SS 304L Square Body Needle Valves Stockist |

| SS 304L High Pressure Square Body NPT Thread Needle Valve | Stainless Steel 304L Round Body Needle Valve |

Application Of SS 304L Needle Valves

Application Industry

For More Information About Stainless Steel 304L Needle Valves please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Frequently Asked Questions About Stainless Steel 304L Needle Valves

Stainless Steel 304L Needle Valve is a fine flow control valve manufactured of low-carbon SS 304L. It is usually applied in chemical, oil and gas, hydraulic and instrumentation systems to precisely control and cut off liquids and gases.

The 304L Stainless Steel L is short form of low carbon. This piece of work increases the weldability and reduces the chances of carbide forming and is therefore suitable in high-temperature and corrosive processes compared to normal 304.

To meet the requirements of the A182 and A276 standards of UNS S30403 and DIN 1.4306 / 1.4307, Aashish Metals produces SS 304L Needle Valves according to the specifications of A182 and A276 in accordance with the requirements of mechanical strength, corrosion resistance, and dimensional accuracy.

Yes, SS 304L Needle Valves are used on high-pressure instrumentation and hydraulics. Their strong construction and finer thread stem gives them the ability to control the flow precisely even in extreme pressure and temperature conditions.

Every valve will be provided with Material Test Reports (MTRs), EN 10204 3.1 certification, and pressure test reports to check the quality and traceability of materials and their agreement with international manufacturing standards.

Applications in oil and gas plants, refineries, power generation units, food processing, pharmaceuticals, and water treatment facilities, where corrosion resistance and flow control of high accuracy is essential, are major areas of use of these valves.

Aashish Metals is a reliable manufacturer and exporter of an MTR-approved 304L Stainless Steel Needle Valve that has a regular quality, proper dimensions, and timely deliveries to both local and foreign customers.

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.