Duplex Steel S31803 S32205 Threaded Fittings Manufacturer

Home › Super Duplex Steel Products › Duplex Steel S31803/S32205 Threaded Fittings

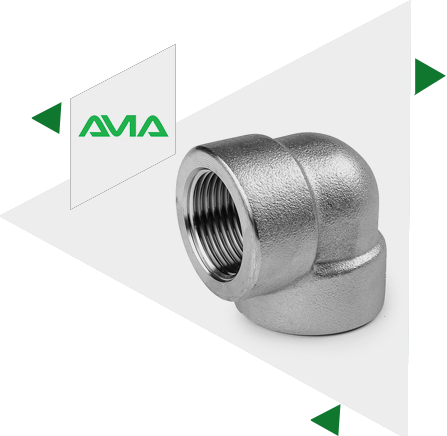

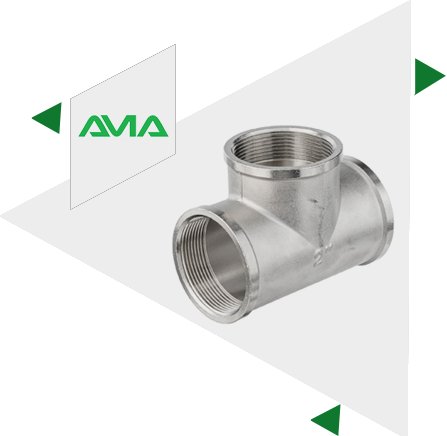

Duplex Steel S31803 Threaded Elbow, S32205 Duplex Steel Threaded Coupling, Duplex Steel S31803 Threaded Tee, S32205 Duplex Steel Threaded Cross, Duplex 2205 Threaded Union, Duplex Steel S31803 Threaded Bushing, S32205 Duplex Steel Threaded Hex Nipple, Duplex Steel S31803 S32205 Threaded Fittings Manufacturer in India

S31803 / S32205 Socketweld Fittings provide great toughness and resistance to corrosive acids. Duplex Steel S31803 / S32205 is a popular grade that offers high tensile strength, higher creep strength, and stress to rupture resistance. It can be utilized in the elevated temperature media and corrosive marine environment. It also provides a corrosion-resistant from sulfuric acids and chloride solutions. Duplex Steel S31803 / S32205 Socketweld Fittings hold the low amount of carbon content to provide resistance to thermal degradation and corrosion due to wielding. S31803 / S32205 is comparatively better than the abrasion-resistant alloy, and possess superior resistant and mechanical properties. Its strain rate is very low due to its high corrosion resistance and hardness. It also provides corrosion-resistant from sulfuric acids and chloride solutions. Our S31803 / S32205 Socketweld Fittings have an additional amount of chromium for resisting the intergranular corrosion in the welding. These fittings offer better corrosion resistance to corrosion from citric, formic, acetic and sulfuric acids.

- Duplex Steel S31803 S32205 Threaded Fittings Specifications

- Duplex Steel S31803 S32205 Threaded Fittings Equivalent Grades

- Duplex Steel S31803/S32205 Threaded Fittings Quality and Test reports

- Duplex Steel S31803/S32205 Threaded Fittings International Standards

- Related Types of Duplex Steel S31803 S32205 Threaded Fitting

- ASTM A182 Duplex Steel S31803 S32205 Threaded Forged Fittings Dimensions Chart

- Duplex Steel S31803 S32205 Threaded Fittings Pressure Rating

- Chemical Composition

- Mechanical Properties of Duplex Steel S31803 S32205 Threaded Fittings

- Duplex Steel S31803/S32205 Threaded Fittings price list

- We supply of variety Duplex Steel S31803/S32205 Threaded Fittings

- Application Of Duplex Steel S31803/S32205 Threaded Fittings

ANSI B1611 Duplex Steel S31803 Threaded Union, UNS S32205 Forged Threaded Bushing, Duplex Steel S31803 High Pressure Threaded Fittings, WNR 14462 Forged Threaded Plug, Duplex Steel S32205 Threaded Pipe Cap, S31803 Duplex Steel 45 Degree Threaded Elbow, UNS S31803 Forged Threaded Reducing Insert, ASTM A182 Duplex Steel S32205 Threaded 90 Degree Elbow Suppliers

ANSI B1611 Duplex Steel S31803 threaded union and UNS S32205 forged threaded bushing are produced to be used in applications needing a high level of joint integrity and long term sealing. These threaded components are Duplex that are very common in high pressure fluid handling systems as they have good mechanical strength with high pitting and stress corrosion cracking resistance. Duplex Steel S31803 high pressure threaded fittings are made of balanced ferritic austenitic micro-structures which ensure trustworthy operation in hostile chloride ambient conditions like platforms offshore, desalination plants and chemical processing plants.

WNR 14462 is a threaded plug and Duplex Steel S32205 threaded pipe cap support that helps to ensure safe maintenance procedures and closures in pipelines and instrumentation networks. S31803 Duplex Steel 45 degree threaded elbow and ASTM A182 Duplex Steel S32205 threaded 90 degree elbow enable continuous directional transitioning with a low pressure drop and constant flow characteristics. UNS S31803 forged threaded reducing insert gives easy connection between different sizes of pipes without any leakage across the transition between threaded systems.

For buyers requiring a broader grade selection, we also supply a complete range of Duplex and Super Duplex steel products, available through our product section at Aashish Metals (Customers looking for higher corrosion resistance can also explore our Super Duplex S32750 S32760 threaded fittings, available here:

Duplex Steel S31803 S32205 Threaded Fittings Specifications

| Dimensions | ASTM A182 / ASME SA182 |

|---|---|

| Standard | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8″ NB to 4″ NB Screwed-Threaded |

| Class | 2000lb/ 3000lb/ 6000lbs |

| From | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, Unions, Equal Tees & Reducing Tees, Plugs. |

Duplex Steel S31803 S32205 Threaded Fittings Equivalent Grades

| STANDARD | UNS | WNR. |

|---|---|---|

| Duplex S31803/S32205 | S31803/S32205 | 1.4462 |

Duplex Steel S31803/S32205 Threaded Fittings Quality and Test reports

- Third Party Inspection

- EN 10204/3.1B

- 100% Radiography Test

- Raw Materials Certificate

- Mill test

Duplex Steel S31803 S32205 Threaded Fittings International Standards

| American Steel Threaded Fittings Standard | |

| Standard Code | Standard Name |

| ANSI ASME SA-182 | Forged fittings |

| ANSI ASME B16.11 | Socket-welding and Threaded forged fittings |

| MSS SP-79 | Socket-welding reducing Inserts |

| MSS SP-83 | Class 3000 steel socket-welding and threaded unions |

| MSS SP-95 | Swaged nipples and round plugs |

| MSS SP-97 | SW,TH and BW ends for integrally reinforced forged branch outlet |

Related Types of Duplex Steel S31803 S32205 Threaded Fitting

S31803/S32205 Threaded Elbow

S31803/S32205 Threaded Tee

S31803/S32205 Threaded Full Coupling

S31803/S32205 Threaded Half Coupling

S31803/S32205 Threaded Cross

S31803/S32205 Threaded Union

S31803/S32205 Threaded Pipe Cap

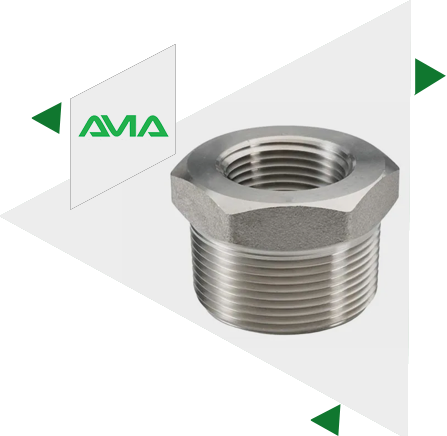

S31803/S32205 Bushing

S31803/S32205 Threaded Plug

S31803/S32205 Threaded Hex Plug

S31803/S32205 Threaded Pipe Nipple

S31803/S32205 Threaded Swage Nipple

Threaded vs Forged vs Socket Weld Fittings Comparison

| Feature | Threaded Fittings | Forged Fittings | Socket Weld Fittings |

|---|---|---|---|

| Connection Type | Threaded joint without welding | Forged and supplied in threaded or socket weld ends | Socket weld joint requiring welding |

| Typical Standards | ASTM A182, ASME B1611, NPT, BSP | ASTM A182, ASME B1611 | ASTM A182, ASME B169 |

| Pressure Rating | Suitable for medium to high pressure | Highest pressure capability | High pressure and high temperature |

| Installation | Easy installation and removal | Requires skilled handling | Requires welding by skilled personnel |

| Leak Resistance | Good sealing performance | Very high leak resistance | Excellent sealing due to welded joint |

| Best Used In | Maintenance lines, low welding environments, quick assembly | High pressure steam, chemical plants, oil and gas | High temperature and high pressure pipelines |

| Cost Efficiency | Low installation cost | Higher cost due to forging | Medium installation cost |

| Typical Industries | Water treatment, chemical dosing, instrumentation | Petrochemical, offshore, refinery | Power plants, boilers, high temperature systems |

ASTM A182 Duplex Steel S31803 S32205 Threaded Forged Fittings Dimensions Chart

| DN | NPS | Center to End NPT Elbow, NPT Tee, NPT Cross A |

Center to End 45 Deg Elbow C |

O.D. of Band H |

Min. Wall Thick. G |

Length of Thread. Minimum (1) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | B | L2 | ||

| 6 | 1/8 | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 21 | 25 | 28 | 17 | 19 | 22 | 22 | 25 | 33 | 3.18 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 25 | 28 | 33 | 19 | 22 | 25 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 28 | 33 | 38 | 22 | 25 | 28 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 33 | 38 | 44 | 25 | 28 | 33 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 38 | 44 | 51 | 28 | 33 | 35 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 1-1/4 | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 1-1/2 | 51 | 60 | 64 | 35 | 43 | 44 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 60 | 64 | 83 | 43 | 44 | 52 | 75 | 86 | 102 | 4.27 | 7.14 | 12.09 | 19.0 | 19.2 |

| 65 | 2-1/2 | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

| 85 | 3 | 86 | 95 | 106 | 64 | 64 | 79 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 106 | 114 | 114 | 79 | 79 | 79 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33.0 |

| DN | NPS | End to End Couplings W |

End to End Caps P |

O.D. D | End Wall Thick. G Minimum |

Length of Thread. Minimum (1) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Class 3000&Class 6000 | Class 3000 | Class 6000 | Class 3000 | Class 6000 | Class 3000 | Class 6000 | B | L2 | ||

| 6 | 1/8 | 32 | 19 | … | 16 | 22 | 4.8 | … | 6.4 | 6.7 |

| 8 | 1/4 | 35 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 10 | 3/8 | 38 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 25 | 1 | 60 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 32 | 1-1/4 | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

| 40 | 1-1/2 | 79 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 50 | 2 | 86 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

| 65 | 2-1/2 | 92 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

| 80 | 3 | 108 | 65 | 68 | 108 | 127 | 19.0 | 22.4 | 25.9 | 30.5 |

| 100 | 4 | 121 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33.0 |

Duplex Steel S31803 S32205 Threaded Fittings Pressure Rating

| ASME B16.11 Pressure-Temperature | |||||

|---|---|---|---|---|---|

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 – 1 inch. | 1 1/4 – 2 inch. | 2 1/2 – 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | – | 935 | 750 | 560 |

| 450 | 232 | – | 725 | 600 | 475 |

| 500 | 260 | – | 510 | 450 | 385 |

| 550 | 288 | – | 300 | 300 | 300 |

We Keep Bulk Stock Of Duplex Steel S31803/S32205 Forged Threaded Fittings At Our Stockyard, Contact Us For Free Sample & Stock List.

Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Duplex S31803 | 0.030max | 2.00 max | 1.00 max | 0.030max | 0.020 max | 22.0-23.0 | 3.0-3.5 | 4.50-6.50 | 0.14-0.20 | 63.72 min |

| Duplex S32205 | 0.030max | 2.00 max | 1.00 max | 0.030max | 0.020 max | 21.0-23.0 | 2.50-3.50 | 4.50-6.50 | 0.08-0.20 | 63.54 min |

Mechanical Properties of Duplex Steel S31803 S32205 Threaded Fittings

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

|---|---|---|---|---|

| S31803 / S32205 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

For Duplex Steel S31803/S32205 Threaded Fittings price list

Request the latest Duplex Steel S31803/S32205 Threaded Fittings List. Please click on the request a quote button or click here to request the updated price list and ready stock information along with your requirement. Aashish Metal & Alloys maintains a stock of all standard items and can export them at best price for Duplex Steel S31803/S32205 Screwed Fittings .

We supply of variety Duplex Steel S31803/S32205 Threaded Fittings

Aashish Metal & Alloys is a Highly Acclaimed Manufacturer & suppliers of Duplex Steel S31803/S32205 Threaded Forged Fittings offering all varieties in all types of S31803/S32205 Duplex Steel in all sizes, with more then 52 countries worldwide.

| Duplex Steel S31803 Threaded Fittings | Duplex Steel S32205 Forged Threaded Fittings |

| Duplex Steel S32205 High Pressure Threaded Fittings | Duplex Steel S31803 Threaded 45 deg. Elbow |

| UNS S31803 Screwed Fittings | Duplex Steel S32205 Forged Threaded Tee |

| Duplex Steel S32205 NPT Threaded Fittings | S31803 Duplex Steel BSP Threaded Elbow |

| Duplex Steel S31803 Threaded 45 Deg Elbow Suppliers | Duplex Steel S32205 90 Degree Threaded Elbow |

| Duplex Steel S32205 Threaded End Cap Dealer | Duplex Steel S31803 Threaded Half Coupling Exporter |

| S31803 Duplex Steel Threaded Tee Stockholder | Duplex Steel S32205 Threaded Reducing Tee Distributors |

| Duplex Steel S32205 Threaded Equal Cross | ANSI B16.11 Duplex Steel S31803 Threaded Pipe Cap |

| UNS S31803 Threaded Unequal Cross | Duplex Steel S32205 High Pressure Screwed Fittings Manufacturer |

| S32205 Duplex Steel Threaded Coupling | Duplex Steel S32205 Threaded Reducing Couplings |

| S31803 Duplex Steel Threaded Plug | S32205 Duplex Steel Swage Nipple |

| DIN 1.4462 Forged Threaded Tee | DIN 1.4462 Threaded Equal Cross |

| Duplex Steel S32205 Threaded Full Coupling | Duplex Steel S31803 Forged Threaded Union |

| Duplex Steel S31803 Bushing | Duplex Steel S32205 Threaded Pipe Nipple |

| Duplex Steel S32205 Bushing | Duplex Steel S31803 Threaded Pipe Nipple |

| S31803 Duplex Steel Hex Head Bushing | Duplex Steel S32205 Hex Head Plug |

| Duplex Steel S32205 Threaded Equal Tee | Duplex Steel S31803 Threaded Half Coupling Stockist |

| ASTM A182 Duplex Steel S31803 Threaded Boss | ASME SA182 Duplex Steel S32205 Threaded Pipe Cap |

| Duplex Steel S32205 Threaded Hex Plug | S31803 Duplex Steel NPT Threaded Street Elbow |

Application Of Duplex Steel S31803/S32205 Threaded Fittings

Application Industry

For More Information About UNS S31803/S32205 Threaded Fittings please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Why Aashish Metals for Duplex Steel S31803 S32205 Threaded Fittings

Aashish Metals is trusted by engineering companies, EPC contractors and industrial buyers for delivering high performance Duplex Steel S31803 S32205 threaded fittings that meet strict quality and dimensional standards. Our high integrity Duplex Stainless Steel grades S31803, S32205 and Duplex 2205 are used to make our threaded elbows, tees, couplings, crosses, unions, bushings, pipe caps and hex plugs and pipe nipples in order to provide excellent strength, corrosion resistance and long term service in harsh operating conditions.

During machining and heat treatment processes, we are very strict to obtain correct thread profiles, smooth surface finish and the ability to handle pressure consistently. All threaded fittings are manufactured based on ASTM A182 and ASME B1611 standards, material testing, PMI checks and documentation are made available to trace them fully.

Our knowledge in forged threaded fittings is also used by buyers in choosing components used in high pressure lines, chemical processing unit, marine systems as well as instrumentation networks. Aashish Metals as one of the biggest manufacturers and suppliers in India, has its attention on quick delivery, volume and quality of dims in all the Duplex threaded parts.

The reason is our promise of quality, timely service, and the full line of Duplex Steel products, which makes us a favorable supplier to Duplex Steel S31803 S32205 threaded fittings to various industries.

Frequently Asked Questions About Duplex Steel S3180 and S32205 Threaded Fittings

The high pressure piping systems and chemical processing lines along with the desalination plants, marine environments and the networks of instruments use duplex steel S31803 S32205 threaded fittings. Their aggressive chloride and mechanical strength properties make them the best to be used in any aggressive chloride environment as well as where easy assembly without welding is to be carried out.

Duplex 2205 threaded fittings have increased yield strength, enhanced pitting strength and enhanced stress corrosion cracking strength as compared to normal grades of stainless steel. They are more reliable in critical industrial systems because they have a balanced austenitic and ferritic structure which results in enhanced durability in rough environments.

Yes, when made as per the ASTM A182 and ASME B1611 standards, Duplex Steel S31803 S32205 threaded fittings can be used in medium and high pressure systems. Other components like threaded elbows, unions, couplings and plugs have high leak resistance even when subjected to high pressures.

Some of the common ones are threaded elbow, threaded tee, threaded coupling, threaded union, threaded cross, threaded hex plug, threaded pipe nipple, threaded pipe cap and threaded bushing. These fittings assist in efficient connection and flow control in Duplex piping networks.

Due to its high content of chromium, molybdenum and nitrogen, Duplex Steel S31803 S32205 offers high pitting, crevice corrosion and stress corrosion cracking resistant. This will guarantee extended service life in the chemical, offshore, marine, and desalination applications.

In situations that meet ASTM A182 material standard and ASME B1611 threading requirements, duplex steel threaded fittings may be substituted with traditional threaded fittings of ASTM A182. They provide similar performance with regard to strength and sealing in high pressure and corrosive systems.

Such fittings usually do PMI test, hardness test, mechanical test, hydro test and dimension test. ASTM A182 supports the integrity of materials and ASME B1611 supports proper threading and pressure management capability.

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Stainless Steel

- Duplex & Super Duplex

- Duplex Steel Fasteners

- Duplex Steel Tube Fittings

- Duplex Steel Manifold Valves

- Duplex Steel Ball Valves

- Duplex Steel Needle & Gauge Valve

- Duplex Steel Pipes & Tubes

- Duplex Steel Pipe Fittings

- Duplex Steel Threaded Fittings

- Duplex Steel Socket Weld Fittings

- Duplex Steel Sheets & Plates

- Duplex Steel Round Bars

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.