Hastelloy Material Manufacturer and Supplier in India

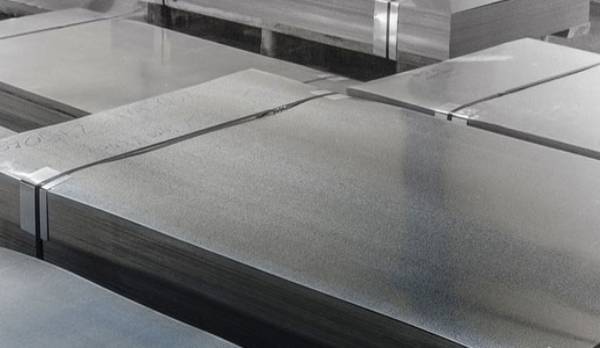

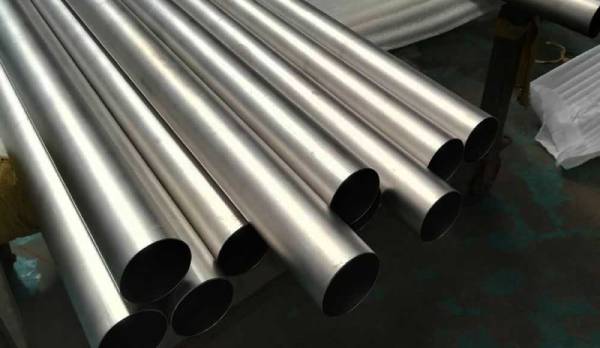

Hastelloy products are nickel based alloy materials supplied for applications requiring resistance to severe corrosion, high temperature, and pressure conditions. Hastelloy pipes, fittings, valves, fasteners, plates, sheets, and bars are some of the items discussed on this page and are produced and supplied in the form of C276, C22, and B2 depending on the industrial requirement.

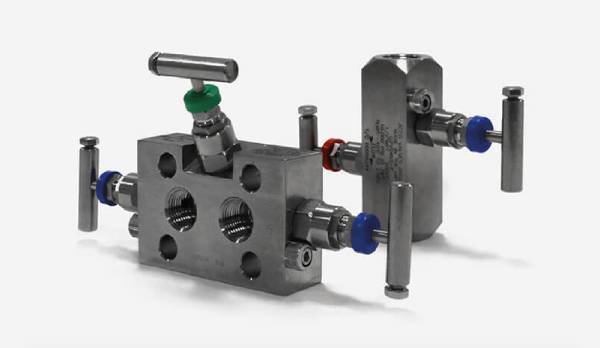

Instrumentation Ball Valves

Needle Valve

Pipes & Tubes

Pipe Fittings

Threaded Fittings

Socket Weld Fittings

- Hastelloy Material and Alloy Grades Covered

- Industrial Applications of Hastelloy Products

- Typical Bimetal Material Combinations

- Typical Chemical Composition of Hastelloy Alloys

- Typical Mechanical Properties of Hastelloy Materials

- Equivalent Grades of Hastelloy Alloys

- Standards, Quality Control, and Supply Scope

Hastelloy Material and Alloy Grades Covered

This is a concentrated supply line of Hastelloy products that is aimed at aggressive chemical and thermal operating conditions using nickel based alloys. The materials provided on this page are chosen to fulfill the challenges of corrosion resistance, mechanical stability, and long service life requirements on industrial systems.

The product range also has Hastelloy grades, C276, C22 and B2 where each one is selected depending on the corrosive media, operating temperature and pressure conditions. The grades are normally outlined in chemical processing, pollution control, oil and gas, as well as high purity industrial products.

Hastelloy products supplied under this category have the same grade across the various product forms to facilitate compatibility and fabrication needs to the system.

Industrial Applications of Hastelloy Products

Hastelloy alloys are used in industries where material failure can lead to operational risk or downtime. The products supplied under this category are commonly used in:

- Chemical processing equipment handling acids and chlorides

- Oil and gas processing and refinery systems

- Marine and offshore environments exposed to seawater

- Heat exchangers, condensers, and thermal systems

- Pharmaceutical and pollution control equipment

Material selection is driven by corrosion resistance, temperature stability, and long term service reliability.

Typical Chemical Composition of Hastelloy Alloys

| Element | Hastelloy C276 | Hastelloy C22 | Hastelloy B2 |

|---|---|---|---|

| Nickel (Ni) | Balance | Balance | Balance |

| Chromium (Cr) | 14.5–16.5% | 20–22.5% | ≤1.0% |

| Molybdenum (Mo) | 15–17% | 12.5–14.5% | 26–30% |

| Iron (Fe) | 4–7% | 2–6% | ≤2.0% |

| Cobalt (Co) | ≤2.5% | ≤2.5% | ≤1.0% |

| Carbon (C) | ≤0.01% | ≤0.01% | ≤0.01% |

| Manganese (Mn) | ≤1.0% | ≤0.5% | ≤1.0% |

| Silicon (Si) | ≤0.08% | ≤0.08% | ≤0.10% |

Typical Mechanical Properties of Hastelloy Materials

| Property | Hastelloy C276 | Hastelloy C22 | Hastelloy B2 |

|---|---|---|---|

| Tensile Strength | ≥690 MPa | ≥690 MPa | ≥760 MPa |

| Yield Strength (0.2%) | ≥283 MPa | ≥310 MPa | ≥345 MPa |

| Elongation | ≥40% | ≥45% | ≥40% |

| Hardness | ≤100 HRB | ≤100 HRB | ≤100 HRB |

Equivalent Grades of Hastelloy Alloys

| Hastelloy Grade | UNS Designation | Common Standards |

|---|---|---|

| Hastelloy C276 | UNS N10276 | ASTM B574, B575, B619, B622 |

| Hastelloy C22 | UNS N06022 | ASTM B574, B575, B619, B622 |

| Hastelloy B2 | UNS N10665 | ASTM B333, B335, B619 |

Standards, Quality Control, and Supply Scope

Depending on the form and grade of products, Hastelloy products are produced and delivered based on the stipulated ASTM and ASME requirements. Traceability of materials is ensured by mill test certificates to support quality checks and quality inspection policies.

The scope of supply incorporates standard sizes and project specific quantities, and has domestic and export documentation support. Industrial procurement and logistics requirements are consistent with inspection coordination and packaging.

Why Choose Us as a Hastelloy Products Manufacturer and Supplier

The supply of Hastelloy products requires meticulous control over material grades, documentation, and application relevance. As a manufacturer and distributor of Hastelloy products, it is oriented towards matching the selection of alloys to the conditions of providing services, as opposed to promoting generic material service options.

They assist in grade confirmation, traceability of the material and procurement coordination in order to ascertain that the material is in line with the project specifications. Technical documentation of products is also provided with the aim of assisting engineering and sourcing teams when executing orders.

Related Alloy Categories

For applications requiring alternative nickel and high performance alloys, related product categories include:

These categories support material selection across different corrosion and temperature ranges.

Frequently Asked Questions About Hastelloy Products

Hastelloy products are used in corrosive and high temperature environments such as chemical processing, oil and gas, marine, and pollution control systems.

This page covers Hastelloy grades including C276, C22, and B2 supplied across multiple product forms.

Yes, Hastelloy products are supplied with mill test certificates to support material traceability and quality verification.

Hastelloy alloys provide higher resistance to corrosion, acids, and chlorides, making them suitable where stainless steel performance is limited.

Yes, Hastelloy products can be supplied for export with appropriate documentation and inspection support.

Grade selection depends on corrosion type, temperature, pressure, and process media. Engineering requirements guide the selection.

For More Information About Hastelloy Products please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Materials

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- Thank You For Connecting

- Duplex and Super Duplex Steel Pipes and Tubes

- Duplex and Super Duplex Steel Threaded Fittings Manufacturer and Supplier

- Duplex Steel S31803 S32205 and Super Duplex S32750 S32760 Pipe Fittings

- Duplex S31803 S32205 Socket Weld Fittings Manufacturer

- Duplex and Super Duplex Steel Socket Weld Fittings

- Duplex and Super Duplex Steel Tube Fittings

- Stainless Steel 316 / 316L Pipes & Tubes

- Stainless Steel 321 Pipes & Tubes

- Inconel Pipes and Tubes

- Home uat

- Stainless Steel Pipe Fittings Manufacturer and Supplier

- Stainless Steel Pipes and Tubes

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.