Nickel Alloy Products

Nickel alloy products in this category come in the form of Nickel Alloy 200 and Nickel Alloy 201. The choice is inclusive of pipes, fittings, fasteners, plates, sheets, and bars which are of certain material requirements. This group is targeted to industrial buyers where the ability of the grade classification, accessibility of product configurations and sourcing consistency are critical.

Nickel Alloy Product Categories

Fasteners

Tube Fittings

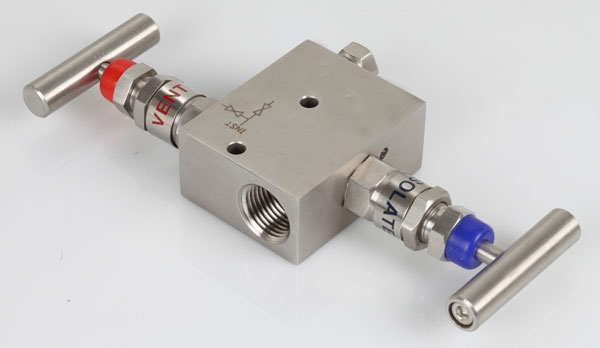

Manifold Valves

Pipe Fittings

Threaded Fittings

Socket weld Fittings

- Nickel Alloy Grades Covered Under This Category

- Industrial Applications of Nickel Alloy Products

- Material Characteristics of Nickel Alloy

- Specification of Nickel Alloy 200 and 201

- Chemical Composition of Nickel Alloy 200 and 201

- Mechanical Properties of Nickel Alloy 200 and 201

- Equivalent Grades of Nickel Alloy 200 and 201

Nickel Alloy Grades Covered Under This Category

This type of product in the nickel alloy category mostly includes Nickel Alloy 200 and Nickel Alloy 201, whose alloys are commercially pure nickel products that are highly specified in industry.

Nickel 200 is chosen because it has very high resistance to alkalis, neutral salts and organic compounds whereas Nickel 201 is chosen because it can resist high temperatures because of low carbon content and resistance to graphitization. These grades are provided in material purity, corrosion resistance and stability of performance where the performance is of utmost importance.

Industrial Applications of Nickel Alloy Products

The nickel alloy products are also used in chemical processing plants, caustic handling systems, heat exchanger, instrumentation lines, marine components and inspection in electrical applications. Their corrosion resistance and steady behavior during thermal stress makes them an ideal component in alkaline mediums, high purity systems and temperature sensitive industrial processes where reliability in the material is required.

Material Characteristics of Nickel Alloy

Nickel Alloy 200 and 201 have good thermal conduction, corrosion resistance in the alkaline and neutral media and are stable in their mechanical properties over a wide temperature. Good formability and weldability are also offered by these alloys and hence are applicable in either pressure bearing systems or precision engineered components of industrial processing and manufacture.

Specification of Nickel Alloy 200 and 201

| Standard | UNS Number | Material Grade | Product Forms Covered |

|---|---|---|---|

| ASTM B160 | N02200 | Nickel Alloy 200 | Bars and Rods |

| ASTM B161 | N02200 | Nickel Alloy 200 | Pipes and Tubes |

| ASTM B162 | N02200 | Nickel Alloy 200 | Sheets and Plates |

| ASTM B163 | N02201 | Nickel Alloy 201 | Heat Exchanger Tubes |

| ASTM B725 | N02201 | Nickel Alloy 201 | Welded Pipes |

Chemical Composition of Nickel Alloy 200 and 201

| Element | Nickel Alloy 200 (%) | Nickel Alloy 201 (%) |

|---|---|---|

| Nickel (Ni) | 99.0 min | 99.0 min |

| Carbon (C) | 0.15 max | 0.02 max |

| Iron (Fe) | 0.40 max | 0.40 max |

| Manganese (Mn) | 0.35 max | 0.35 max |

| Silicon (Si) | 0.35 max | 0.35 max |

| Copper (Cu) | 0.25 max | 0.25 max |

| Sulfur (S) | 0.01 max | 0.01 max |

Mechanical Properties of Nickel Alloy 200 and 201

| Property | Nickel Alloy 200 | Nickel Alloy 201 |

|---|---|---|

| Tensile Strength | 380 MPa min | 380 MPa min |

| Yield Strength (0.2%) | 103 MPa min | 103 MPa min |

| Elongation | 40% min | 40% min |

| Hardness | 100 HRB max | 100 HRB max |

| Density | 8.89 g/cm³ | 8.89 g/cm³ |

Equivalent Grades of Nickel Alloy 200 and 201

| Standard | Nickel Alloy 200 | Nickel Alloy 201 |

|---|---|---|

| UNS | N02200 | N02201 |

| DIN | 2 | 2 |

| EN | Ni 99.2 | Ni 99.2 |

| ISO | Ni 99.2 | Ni 99.2 |

| JIS | NW 2200 | NW 2201 |

Manufacturing and Supply Capabilities for Nickel Alloy Products

The supply of nickel alloy products must be closely controlled in terms of quality of raw material, dimensional accuracy and documentation. Being a manufacturer and supplier of nickel alloys, material is supplied with grade verification, mill test certification and inspection coordination when necessary. Its ability to supply has been helpful in standard industrial applications and also in project-based acquisition where it is packaged in appropriate packages to both local and international delivery.

Why Source Nickel Alloy Products from Aashish Metals

A purchase of nickel alloy products is not just about a grade choice. It involves checking of material purity, regulation of chemical composition, and compliance with operating conditions of the application. Aashish metals collaborates with procurement and engineering units to make sure that Nickel Alloy 200 and 201 is appropriate prior to making orders.

Traceable mill test certificates, dimensional inspection, and third party inspection coordination when necessary assist in material supply. Nickel alloy products are made available in various shapes with restricted tolerances to satisfy piping, fabrication, and assembly needs. Export and domestic projects, packaging, documentation and transportation arrangements are addressed to ensure integrity of the material and consistency in material delivery.

Related Alloy Product Categories

Frequently Asked Questions About Nickel Alloy Products

Nickel alloy products are used in chemical processing, alkaline handling, heat exchangers, instrumentation systems, marine components, and electrical applications where corrosion resistance and thermal stability are required.

This category primarily includes Nickel Alloy 200 and Nickel Alloy 201, which are commercially pure nickel grades selected based on temperature limits, corrosion resistance, and application requirements.

Nickel Alloy 200 is suitable for general industrial and chemical environments, while Nickel Alloy 201 has lower carbon content and is preferred for high-temperature applications to prevent graphitization.

Yes, Nickel Alloy 201 is commonly specified for elevated temperature environments due to its thermal stability and resistance to carbon-related degradation.

Nickel alloy products are supplied with mill test certificates confirming chemical composition, mechanical properties, and grade compliance as per applicable standards.

Nickel alloy products are supplied in multiple forms including pipes, tubes, pipe fittings, tube fittings, valves, fasteners, sheets, plates, and round bars to support industrial systems and fabrication needs.

Yes, nickel alloy products can be supplied for domestic and export projects with appropriate documentation, inspection coordination, and packaging aligned with international shipping requirements.

For More Information About Nickel Alloy Products please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Materials

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- Thank You For Connecting

- Duplex and Super Duplex Steel Pipes and Tubes

- Duplex and Super Duplex Steel Threaded Fittings Manufacturer and Supplier

- Duplex Steel S31803 S32205 and Super Duplex S32750 S32760 Pipe Fittings

- Duplex S31803 S32205 Socket Weld Fittings Manufacturer

- Duplex and Super Duplex Steel Socket Weld Fittings

- Duplex and Super Duplex Steel Tube Fittings

- Stainless Steel 316 / 316L Pipes & Tubes

- Stainless Steel 321 Pipes & Tubes

- Inconel Pipes and Tubes

- Home uat

- Stainless Steel Pipe Fittings Manufacturer and Supplier

- Stainless Steel Pipes and Tubes

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.