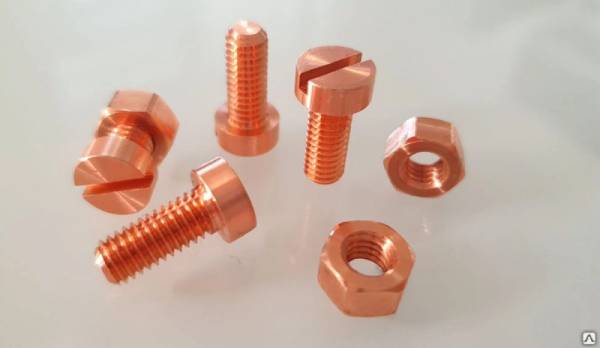

copper nickel Products

In this category, Copper Nickel products, also referred to as cupro nickel, are supplied in the form of pipes, tubes, fittings, valves, fasteners, and round bars that are manufactured in 90/10 grade and 70/30 grade. These copper nickel alloys are chosen when it is needed to have reliable working conditions in seawater, marine and corrosive industrial environments. The product line is used in piping, heat exchange and fluid handling systems where resistance to corrosion, erosion and long-term service stability is needed.

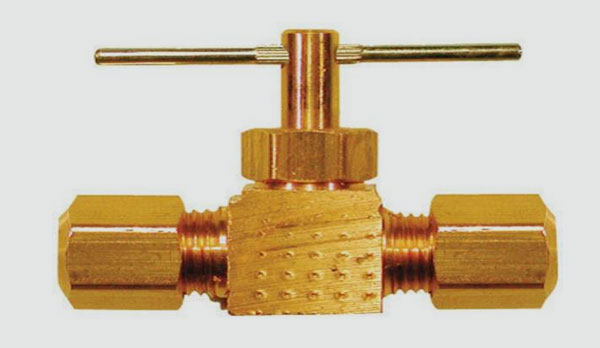

Instrumentation Ball Valves

Threaded Fittings

Socket Weld Fittings

- Copper Nickel Grades and Alloy Composition

- Copper Nickel Product Specification

- Copper Nickel Products for Marine and Industrial Applications

- Copper Nickel Chemical Composition

- Copper Nickel Mechanical Properties

- Copper Nickel Equivalent Grades

- Copper Nickel Product Standards and Quality Control

- Why Choose Us for Copper Nickel Products

- Frequently Asked Questions About Copper Nickel Products

Copper Nickel Grades and Alloy Composition

Copper Nickel are the alloys commonly offered in 90/10 and 70/30 which are based on the operating conditions and system requirement.

Copper Nickel 90/10 is very effective against seawater corrosion and biofouling. It is mostly applied in moderate-speed seawater systems, condensers, heat exchanger, and marine piping where long life expectancy is needed.

Copper-Nickel 70/30 has better Nickel content, giving it better mechanical strength and a higher level of erosion corrosion resistance. This grade is sponsored in high velocity seawater lines, offshore platforms and high marine service applications.

Both grades exhibit consistent mechanical properties even in variations of temperature and are commonly used in long term service in harsh environments.

Copper Nickel Product Specification

| Specification Parameter | Details |

|---|---|

| Material | Copper Nickel Alloy (Cupro Nickel) |

| Grades | 90/10, 70/30 |

| Product Forms | Pipes, Tubes, Pipe Fittings, Tube Fittings, Valves, Fasteners, Round Bars |

| Manufacturing Type | Seamless, Welded, Machined (as applicable) |

| Applicable Standards | ASTM and ASME standards (as applicable by product type) |

| Application Areas | Marine, Seawater Systems, Offshore Installations, Industrial Fluid Handling |

| Corrosion Resistance | Excellent resistance to seawater corrosion and erosion |

| Documentation | Mill Test Certificates, Inspection and Traceability Documents |

Copper Nickel Products for Marine and Industrial Applications

Application Industry

Seawater intake and discharge piping

Heat exchangers and condenser tubes

Shipbuilding and marine engineering systems

Offshore oil and gas installations

Copper Nickel Chemical Composition

| Element | Copper Nickel 90/10 | Copper Nickel 70/30 |

|---|---|---|

| Copper (Cu) | Balance | Balance |

| Nickel (Ni) | 9.0 – 11.0% | 29.0 – 33.0% |

| Iron (Fe) | 1.0 – 2.0% | 0.4 – 1.0% |

| Manganese (Mn) | ≤ 1.0% | ≤ 1.0% |

| Zinc (Zn) | ≤ 0.5% | ≤ 0.5% |

| Lead (Pb) | ≤ 0.02% | ≤ 0.02% |

Note: Composition ranges are typical for Cu-Ni 90/10 and 70/30 alloys used in marine and industrial applications.

Copper Nickel Mechanical Properties

| Property | Copper Nickel 90/10 | Copper Nickel 70/30 |

|---|---|---|

| Tensile Strength | 300 – 380 MPa | 360 – 450 MPa |

| Yield Strength | 105 – 150 MPa | 125 – 170 MPa |

| Elongation | ≥ 30% | ≥ 30% |

| Hardness | Moderate | Moderate to High |

| Density | ~8.9 g/cm³ | ~8.9 g/cm³ |

Note: Mechanical values may vary based on product form, processing method, and applicable standards.

Copper Nickel Equivalent Grades

| Copper Nickel Grade | UNS Number | Common Equivalent Designation |

|---|---|---|

| Copper Nickel 90/10 | C70600 | CuNi10Fe1Mn |

| Copper Nickel 70/30 | C71500 | CuNi30Mn1Fe |

| Cupro Nickel 90/10 | C70600 | EN CW352H |

| Cupro Nickel 70/30 | C71500 | EN CW354H |

These equivalent grades are commonly referenced across ASTM, EN, and international marine specifications.

Copper Nickel Product Standards and Quality Control

The manufacturing and supply of Copper Nickel products to customers is done according to the relevant ASTM and ASME standards depending on the type and use of the product. The supply of materials are regulated in terms of chemical composition, dimensional accuracy and mechanical properties.

Quality and documentation support includes:

- Mill test certificates for material traceability

- Dimensional and visual inspection records

- Documentation aligned with project specifications

Additional inspection or testing requirements can be coordinated based on customer or third-party inspection needs.

Why Choose Us for Copper Nickel Products

Supplying Copper Nickel products requires technical understanding of alloy behavior, grade selection, and application compatibility.

Our approach focuses on:

- Accurate confirmation of grades and specifications

- Consistent supply across multiple Copper Nickel product forms

- Documentation alignment to engineering and procurement requirements

- Coordination for inspection, packaging, and delivery

This ensures Copper Nickel products integrate reliably into marine and industrial systems while reducing sourcing and compliance risks.

Related Alloy Product Categories

Copper Nickel products are often specified alongside other corrosion-resistant alloys depending on system design and service conditions. Related material categories include:

Evaluating compatible alloys during the design stage supports long-term system performance and material compatibility.

Frequently Asked Questions About Copper Nickel Products

Copper Nickel products are commonly used in marine, offshore, and industrial systems involving seawater, heat exchange, and corrosive environments.

90/10 is suitable for moderate seawater conditions, while 70/30 offers higher strength and better resistance to erosion corrosion in high-velocity systems.

Yes. Copper Nickel alloys are specifically designed for long-term exposure to seawater and resist chloride corrosion and biofouling.

Copper Nickel pipes, tubes, and fittings are supplied in accordance with relevant ASTM and ASME standards.

Yes. Copper Nickel tube fittings and valves are commonly used in instrumentation and control lines operating in corrosive environments.

Common Copper Nickel products and grades are maintained in ready stock for standard sizes. Availability depends on product type, grade, and project requirements.

For More Information About Copper Nickel please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Materials

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- Thank You For Connecting

- Duplex and Super Duplex Steel Pipes and Tubes

- Duplex and Super Duplex Steel Threaded Fittings Manufacturer and Supplier

- Duplex Steel S31803 S32205 and Super Duplex S32750 S32760 Pipe Fittings

- Duplex S31803 S32205 Socket Weld Fittings Manufacturer

- Duplex and Super Duplex Steel Socket Weld Fittings

- Duplex and Super Duplex Steel Tube Fittings

- Stainless Steel 316 / 316L Pipes & Tubes

- Stainless Steel 321 Pipes & Tubes

- Inconel Pipes and Tubes

- Home uat

- Stainless Steel Pipe Fittings Manufacturer and Supplier

- Stainless Steel Pipes and Tubes

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.