Inconel 601 Threaded Fittings

Inconel 601 Forged Threaded Tee Manufacturer in India, 601 Inconel Threaded Coupling, Alloy 601 Forged Threaded Pipe Nipple, Alloy 601 Screwed Fittings, Nickel Alloy 601 Threaded Fittings, Inconel Alloy 601 Threaded Cross, Alloy 601 Threaded Elbow Stockist In India.

Aashish Metal & Alloys is a standard manufacturer and supplier of Inconel 601 Threaded Fittings, which has parallel corrosion resistance.

It is titanium stabilized, warmth resistant and austenitic alloy that is usually used for temperature provider within the variety of a 1000 Deg to 1600 Deg F. Inconel Alloy UNS N06601 Threaded Bushing Fittings is specifically utilized in features that contain intermittent and non-stop temperature provider this is in the carbide precipitation variety of 800 Deg to 1500 Deg F. It is fantastic within the organisation of titanium addition of no much less than instances the content material of carbon in it. Well, this addition of titanium prevents or reduces carbide precipitation all through welding and within the variety of 800 Deg to 1500 Deg F provider forms.

- Inconel 601 Threaded Fittings Specifications

- Inconel 601 Threaded Fittings Equivalent Grades

- Inconel 601 Threaded Fittings Quality and Test reports

- Inconel 601 Threaded Fittings International Standards

- Related Types Of Inconel 601 Threaded Fittings

- ASTM B564 Inconel 601 Threaded Forged Fittings Dimensions Chart

- Inconel 601 Threaded Fittings Pressure Rating

- Chemical Composition

- Mechanical Properties

- Inconel 601 Threaded Fittings price list

- We supply of variety Inconel 601 Threaded Fittings

- Application Of Inconel 601 Threaded Fittings

Inconel® Alloy 601 Forged Threaded Reducing Insert, ANSI B16.11 Inconel 601 Threaded Union, Alloy 601 45 Deg Threaded Elbow, UNS N06601 Bushing, Inconel® Alloy 601 Threaded Plug, 2.4851 High Pressure Threaded Fittings, Alloy 601 Threaded Pipe Cap, ASTM B564 Inconel 601 Threaded 90 degree Elbow Suppliers in Mumbai, India.

However, with the motive of imparting maximum beneficial resistance to intergranular corrosion and additionally to polyphonic acid strain corrosion cracking in provider temperatures at variety of 1500 Deg to 1650 Deg F, an air cool may also possibly be used. Inconel Alloy WNR 2.4816 Threaded Plug Fittings have a few exquisite capabilities consisting of having oxidation resistant for as much as 1600 Deg F. It receives pretty stabilized in competition to weld warmth affected zone (HAZ) intergranular corrosion. It possesses precise resistance to intergranular corrosion while welded or worked in temperatures by means of manner of getting carbide precipitation variety of 427 Deg Celsius to 818 Deg Celsius. It is weldable with precise grace by maximum welding processes.

Oxyacetylene welding isn’t suggested, due to capability carbon increase within the weld region. Owing to intergranular carbide precipitation, it could be welded without any lack of corrosion resistance and post-weld annealing isn’t usually needed, aside from provider in extra extreme states. It may be started out at 1149 Deg Celsius and finished at 871 Deg Celsius. However, it’s far appropriate for applications in precise fitness wherein unstabilised chromium nickel steel, might be susceptible to intergranular corrosion. Nickel-Alloy 601 Threaded Lateral Tee Fittings gives precise corrosion resistance in maximum herbal waters (commercial and rural), furnished the salt, chloride and concentrations of natural and hydrochloric acids are low.

Inconel 601 Threaded Fittings Specifications

| Dimensions | ASTM B564 / ASME SB564 |

|---|---|

| Standard | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8″ NB to 4″ NB Screwed-Threaded |

| Class | 2000lb/ 3000lb/ 6000lbs |

| From | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, Unions, Equal Tees & Reducing Tees, Plugs. |

Inconel 601 Threaded Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |

Inconel 601 Threaded Fittings Quality and Test reports

- Third Party Inspection

- EN 10204/3.1B

- 100% Radiography Test

- Raw Materials Certificate

- Mill test

Inconel 601 Threaded Fittings International Standards

| American Steel Threaded Fittings Standard | |

| Standard Code | Standard Name |

| ANSI ASME SA-182 | Forged fittings |

| ANSI ASME B16.11 | Socket-welding and Threaded forged fittings |

| MSS SP-79 | Socket-welding reducing Inserts |

| MSS SP-83 | Class 3000 steel socket-welding and threaded unions |

| MSS SP-95 | Swaged nipples and round plugs |

| MSS SP-97 | SW,TH and BW ends for integrally reinforced forged branch outlet |

We Supplied a Comprehensive Range Of Inconel 601 Threaded Fittings

Related Types Of Inconel 601 Threaded Fittings

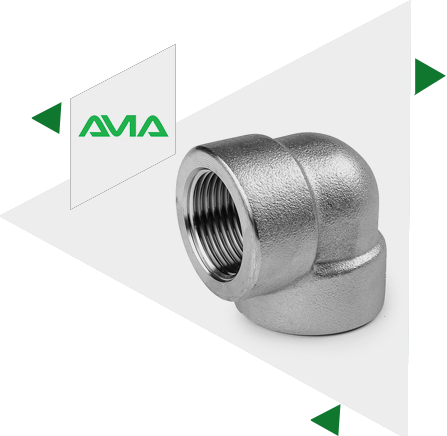

Inconel 601 Threaded Elbow

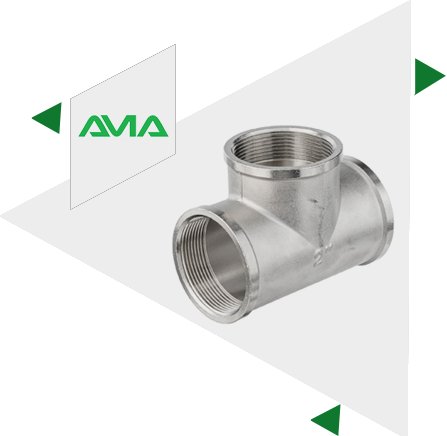

Inconel 601 Threaded Tee

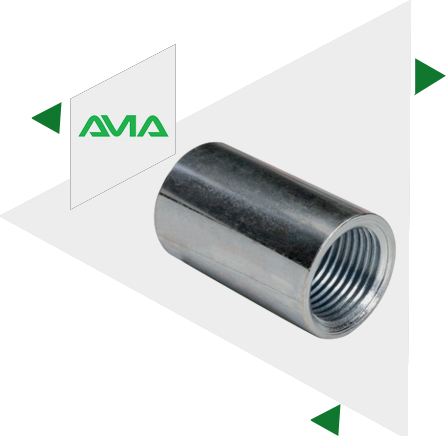

Inconel 601 Threaded Full Coupling

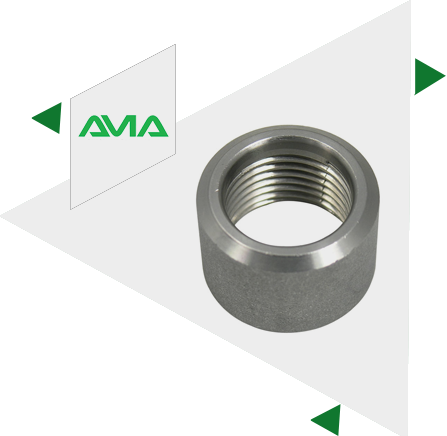

Inconel 601 Threaded Half Coupling

Inconel 601 Threaded Cross

Inconel 601 Threaded Union

Inconel 601 Threaded Pipe Cap

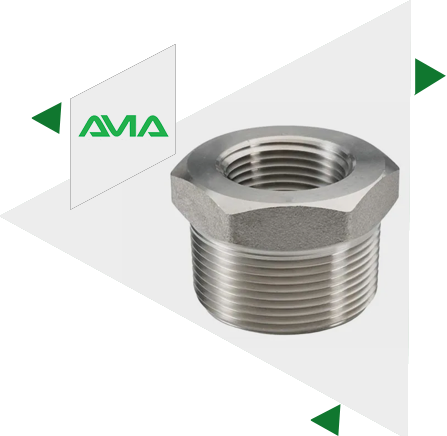

Inconel 601 Bushing

Inconel 601 Threaded Plug

Inconel 601 Threaded Hex Plug

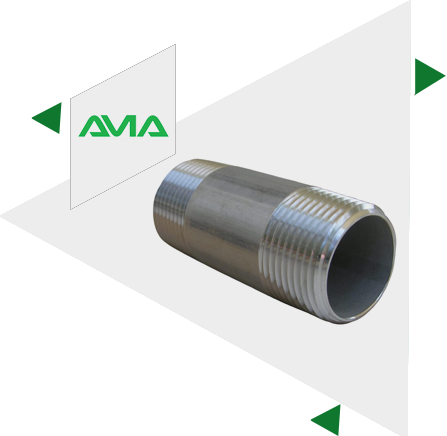

Inconel 601 Threaded Pipe Nipple

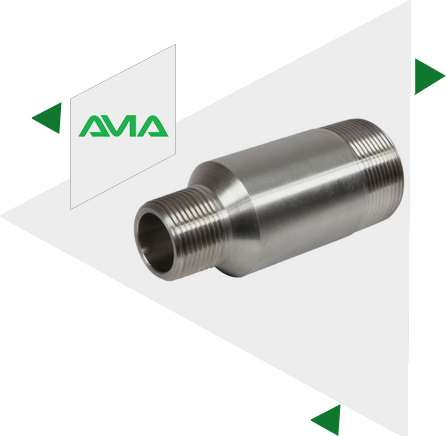

Inconel 601 Threaded Swage Nipple

ASTM B564 Inconel 601 Threaded Forged Fittings Dimensions Chart

| DN | NPS | Center to End NPT Elbow, NPT Tee, NPT Cross A |

Center to End 45 Deg Elbow C |

O.D. of Band H |

Min. Wall Thick. G |

Length of Thread. Minimum (1) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | B | L2 | ||

| 6 | 1/8 | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 21 | 25 | 28 | 17 | 19 | 22 | 22 | 25 | 33 | 3.18 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 25 | 28 | 33 | 19 | 22 | 25 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 28 | 33 | 38 | 22 | 25 | 28 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 33 | 38 | 44 | 25 | 28 | 33 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 38 | 44 | 51 | 28 | 33 | 35 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 1-1/4 | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 1-1/2 | 51 | 60 | 64 | 35 | 43 | 44 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 60 | 64 | 83 | 43 | 44 | 52 | 75 | 86 | 102 | 4.27 | 7.14 | 12.09 | 19.0 | 19.2 |

| 65 | 2-1/2 | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

| 85 | 3 | 86 | 95 | 106 | 64 | 64 | 79 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 106 | 114 | 114 | 79 | 79 | 79 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33.0 |

| DN | NPS | End to End Couplings W |

End to End Caps P |

O.D. D | End Wall Thick. G Minimum |

Length of Thread. Minimum (1) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Class 3000&Class 6000 | Class 3000 | Class 6000 | Class 3000 | Class 6000 | Class 3000 | Class 6000 | B | L2 | ||

| 6 | 1/8 | 32 | 19 | … | 16 | 22 | 4.8 | … | 6.4 | 6.7 |

| 8 | 1/4 | 35 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 10 | 3/8 | 38 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 25 | 1 | 60 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 32 | 1-1/4 | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

| 40 | 1-1/2 | 79 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 50 | 2 | 86 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

| 65 | 2-1/2 | 92 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

| 80 | 3 | 108 | 65 | 68 | 108 | 127 | 19.0 | 22.4 | 25.9 | 30.5 |

| 100 | 4 | 121 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33.0 |

Inconel 601 Threaded Fittings Pressure Rating

| ASME B16.11 Pressure-Temperature | |||||

|---|---|---|---|---|---|

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 – 1 inch. | 1 1/4 – 2 inch. | 2 1/2 – 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | – | 935 | 750 | 560 |

| 450 | 232 | – | 725 | 600 | 475 |

| 500 | 260 | – | 510 | 450 | 385 |

| 550 | 288 | – | 300 | 300 | 300 |

We Keep Bulk Stock Of Inconel 601 Forged Threaded Fittings At Our Stockyard, Contact Us For Free Sample & Stock List.

Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Cu | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Inconel 601 | 0.10 max | 1.00 max | 0.50 max | – | 0.015 max | 21.00-25.00 | 1.00 max | 58-63 | Balance |

Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80000 , MPa – 550 | Psi – 30000 , MPa – 205 | 30 % |

For Inconel 601 Threaded Fittings price list

Request the latest Inconel 601 Threaded Fittings List. Please click on the request a quote button or click here to request the updated price list and ready stock information along with your requirement. Aashish Metal & Alloys maintains a stock of all standard items and can export them at best price for 601 Inconel Screwed Fittings .

We supply of variety Inconel 601 Threaded Fittings

Aashish Metal & Alloys is a Highly Acclaimed Manufacturer & suppliers of Inconel 601 Threaded Forged Fittings offering all varieties in all types of 601 Inconel in all sizes, with more then 52 countries worldwide.

| Inconel 601 Threaded Fittings | Inconel 601 Forged Threaded Fittings |

| Alloy 601 High Pressure Threaded Fittings | Inconel 601 Threaded 45 deg. Elbow |

| UNS N06601 Screwed Fittings | Inconel 601 Forged Threaded Tee |

| Inconel 601 NPT Threaded Fittings | Inconel® Alloy 601 BSP Threaded Elbow |

| Alloy 601 Threaded 45 Deg Elbow Suppliers | Inconel 601 90 Degree Threaded Elbow |

| Inconel 601 Threaded End Cap Dealer | Inconel® Alloy 601 Threaded Half Coupling Exporter |

| Inconel Alloy 601 Threaded Tee Stockholder | Alloy 601 Threaded Reducing Tee Distributors |

| Inconel® Alloy 601 Threaded Equal Cross | ANSI B16.11 Inconel 601 Threaded Pipe Cap |

| Inconel® Alloy 601 Threaded Unequal Cross | Alloy 601 High Pressure Screwed Fittings Manufacturer |

| 601 Inconel Threaded Coupling | Alloy 601 Threaded Reducing Couplings |

| Inconel® Alloy 601 Threaded Plug | 601 Inconel Swage Nipple |

| DIN 2.4851 Forged Threaded Tee | Nickel Alloy 601 Threaded Equal Cross |

| Inconel 601 Threaded Full Coupling | Inconel® Alloy 601 Forged Threaded Union |

| Inconel 601 Bushing | Alloy 601 Threaded Pipe Nipple |

| Inconel 601 Bushing | Inconel Alloy 601 Threaded Pipe Nipple |

| Alloy 601 Hex Head Bushing | Inconel® Alloy 601 Hex Head Plug |

| Alloy 601 Threaded Equal Tee | Inconel 601 Threaded Half Coupling Stockist |

| ASTM B564 Inconel 601 Threaded Boss | ASME SB564 Alloy 601 Threaded Pipe Cap |

| Inconel® Alloy 601 Threaded Hex Plug | Inconel® Alloy 601 NPT Threaded Street Elbow |

Application Of Inconel 601 Threaded Fittings

Application Industry

For More Information About Inconel 601 Threaded Fittings please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Products

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.