Stainless Steel 321 Pipes & Tubes

Stainless Steel 321 Pipes and Tubes Supplier and Manufacturer

Aashish Metal and Alloys are distributors of stainless steel 321 pipes and tubes in seamless and welded versions to satisfy the industrial needs and project based needs. Matter is supplied in accordance with ASTM A312 TP321 to pipes and ASTM A213 TP321 to tubes, regulated chemistry, regular mechanical characteristics, and traceable records. We offer a variety of supplies, which facilitates domestic and export purchasing, size flexibility, inspection organization, and specification adjustment in accordance with the end-use conditions.

- Stainless Steel 321 Pipes and Tubes Overview

- Stainless Steel 321 Pipes and Tubes Specifications

- Stainless Steel 321 Pipes & Tubes Quality and Test Reports

- Stainless Steel 321 Pipes and Tubes Equivalent Grades

- Stainless Steel 321 Pipes and Tubes Product Range

- Stainless Steel 321 Pipes and Tubes Stock and Supply Range

- Stainless Steel 321 Pipe and Tube Dimensions

- Stainless Steel 321 Pipes and Tubes Pressure Ratings

- Chemical Composition of Stainless Steel 321 Pipes and Tubes

- Mechanical Properties of Stainless Steel 321 Pipes and Tubes

- Stainless Steel 321 Pipes and Tubes Price List

Stainless Steel 321 Pipes and Tubes Overview

Stainless Steel 321, also known as UNS S32100 and DIN 1.4541, has some titanium to stabilize carbon and inhibit the formation of carbides during welding or even when subjected to high temperatures. This feature renders 321 stainless steel pipes and tubes to be applicable in fabrication areas that have limited or impractical post-weld heat treatment. The grade has good resistance to oxidation and scaling in high temperature and still has corrosion resistance characteristics of austenitic stainless steels.

In high-temperature processes using piping system with high precision of dimensions, stainless steel 321 tubes have been used with fittings that match the tube in order to achieve leaks free assembly. To connect instrumentation and process You can use our stainless steel 321 tube fittings which are designed with the purpose of maintaining a uniform OD and ensuring the integrity of joints.

When it comes to applications in which a higher temperature alloy is required than austenitic stainless steels, procurement departments are also able to consider nickel-based alloys in applications where such alloys are employed. Incoloy 800 pipes and tubes are often used in combination with SS 321 in order to select certain service conditions.

Stainless Steel 321 Pipes and Tubes Specifications

Stainless Steel 321 pipes and tubes are manufactured in accordance with internationally recognised standards to ensure consistency in dimensions, chemistry, and mechanical performance.

| Parameter | Details |

|---|---|

| Material Grade | Stainless Steel 321 |

| UNS | S32100 |

| DIN | 1.4541 |

| Pipe Standard | ASTM A312 TP321 |

| Tube Standard | ASTM A213 TP321 |

| Manufacturing Type | Seamless / Welded |

| Size Range | As per ASTM standards |

| Surface Finish | Mill finish, pickled, polished |

| End Type | Plain end, bevel end |

Stainless Steel 321 Pipes and Tubes Equivalent Grades

Equivalent grade references help align stainless steel 321 material with international specifications used in global projects.

| Standard | Grade |

|---|---|

| ASTM | TP321 |

| UNS | S32100 |

| DIN | 1.4541 |

| EN | X6CrNiTi18-10 |

| JIS | SUS 321 |

Stainless Steel 321 Pipes and Tubes Quality and Test Reports

All stainless steel 321 pipes and tubes supplied by Aashish Metal and Alloys are supported by documented quality control and inspection processes aligned with customer and project requirements.

- Mill Test Certificates (EN 10204 3.1)

- Third-party inspection on request

- Chemical analysis verification

- Mechanical test reports

- PMI testing for material grade confirmation

- Visual and dimensional inspection

- Non-destructive testing as specified

Stainless Steel 321 Pipes and Tubes Product Range

Aashish Metal and Alloys supplies stainless steel 321 pipes and tubes in a comprehensive range of forms to suit fabrication, installation, and operational needs.

SS 321 Seamless Pipe

SS 321 ERW Pipe

SS 321 Welded Pipe

Stainless Steel 321 Seamless Tube

321 Stainless Steel Heat Exchanger Tube

321 Stainless Steel Square Tube

Stainless Steel 321 Pipes and Tubes Stock and Supply Range

We carry standard, as well as project-specific needs, and are available in the popular sizes and schedules. Pipes and tubes of stainless steel 321 may be supplied in cut or full random length, depending on the requirements of the application, packaged in either domestic handling or export shipment required.

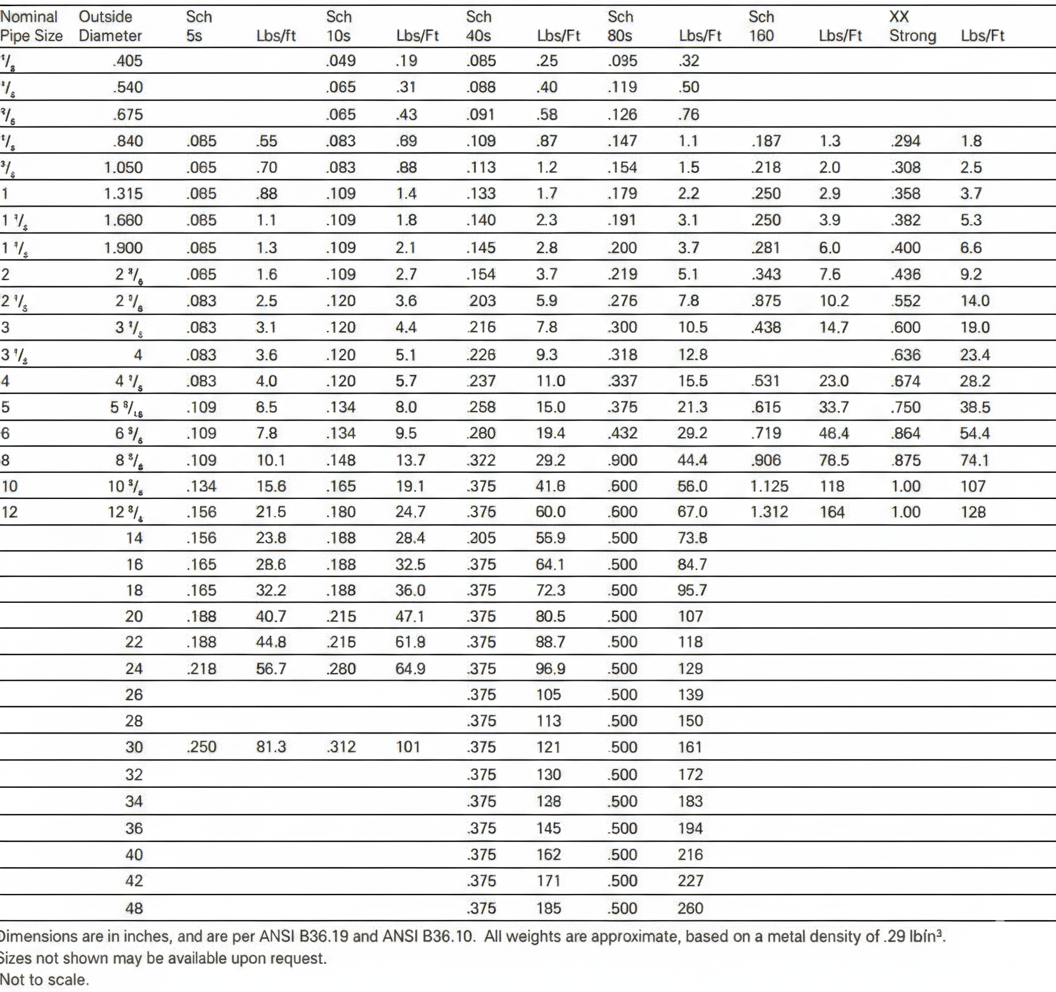

Stainless Steel 321 Pipe and Tube Dimensions

Stainless steel 321 pipes and tubes are available in dimensional ranges defined by ASTM standards, covering a wide selection of nominal pipe sizes, outside diameters, and wall thicknesses.

Stainless Steel 321 Pipes and Tubes Pressure Ratings

The pressure rating of stainless steel 321 pipes and tubes varies with size, wall thickness, temperature and design code used. It can be used in high temperature service applications where pressure is needed to be maintained, and the stability of welds is needed.

| NPS (Inch) | Schedule 10S (psi) | Schedule 40S (psi) | Schedule 80S (psi) |

|---|---|---|---|

| 1/2 | 2,300 | 3,300 | 4,600 |

| 3/4 | 2,100 | 3,100 | 4,400 |

| 1 | 2,000 | 2,900 | 4,100 |

| 1 1/2 | 1,800 | 2,600 | 3,700 |

| 2 | 1,700 | 2,500 | 3,500 |

| 3 | 1,500 | 2,200 | 3,100 |

| 4 | 1,400 | 2,000 | 2,900 |

| 6 | 1,200 | 1,700 | 2,500 |

| 8 | 1,000 | 1,500 | 2,200 |

| 10 | 900 | 1,300 | 2,000 |

| 12 | 850 | 1,200 | 1,800 |

Chemical Composition of Stainless Steel 321 Pipes and Tubes

| Element | Typical Content (%) |

|---|---|

| Carbon | ≤ 0.08 |

| Chromium | 17.0 – 19.0 |

| Nickel | 9.0 – 12.0 |

| Titanium | ≥ 5 × C |

| Manganese | ≤ 2.0 |

| Silicon | ≤ 1.0 |

| Phosphorus | ≤ 0.045 |

| Sulfur | ≤ 0.03 |

Mechanical Properties of Stainless Steel 321 Pipes and Tubes

| Property | Typical Value |

|---|---|

| Tensile Strength | ≥ 515 MPa |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness | As per ASTM limits |

Stainless Steel 321 Pipes and Tubes Price List

| Product | Size Range | Standard | Price |

|---|---|---|---|

| SS 321 Seamless Pipes | NPS 1/8” to 24” | ASTM A312 TP321 | Price on Request |

| SS 321 Welded Pipes | NPS 1/2” to 48” | ASTM A312 TP321 | Price on Request |

| SS 321 Seamless Tubes | OD 6 mm to 114.3 mm | ASTM A213 TP321 | Price on Request |

| SS 321 Welded Tubes | OD 12.7 mm to 219.1 mm | ASTM A213 TP321 | Price on Request |

Note: Prices are indicative and depend on size, schedule, quantity, testing scope, and market conditions.

Contact Aashish Metal and Alloys for Stainless Steel 321 Pipes and Tubes Price

Applications of Stainless Steel 321 Pipes and Tubes

Application Industry

Common application areas include:

Heat exchangers and condensers

Exhaust manifolds and thermal processing systems

Related Links

Why Choose Aashish Metal and Alloys for Stainless Steel 321 Pipes and Tubes

Aashish Metal and Alloys provides stainless steel 321 pipes and tubes with emphasis on specification control, traceability, and applicability of the product on the high-temperature service environment and corrosive services. Technical review of each order is done to make sure that it meets the requirements of ASTM A312 TP321 of pipes and ASTM A213 TP321 of tubes in terms of chemistry, dimension, and delivery condition.

Our seamless welded SS 321 pipes and tubes are available at SS 321 pressure requirement, fabrication and service exposure. The choice of the materials is adjusted to the usage where intergranular corrosion and thermal stability are of paramount importance, including heat exchangers, refinery piping, and power plants.

All supplies are backed up with Mill Test Certificate according to EN 10204 3.1, third-party inspection is optional, and PMI test and NDT organization are done according to project or export requirements. This will provide uniformity when carrying out quality audits and site acceptance.

When packing stainless steel 321 pipes and tubes, domestic and international orders are packed in order to preserve the surface finish and dimensional integrity during transportation. Our team provides quick quotation turnaround with unequivocal technical assurance on sizes, schedules and standards and assists procurement departments to swiftly pass from enquiry to action.

Frequently Asked Questions on Stainless Steel 321 Pipes & Tubes

Stainless Steel 321 pipes are used in high-temperature and cyclic heating applications where resistance to intergranular corrosion is critical. Typical uses include heat exchangers, exhaust systems, refinery piping, and thermal processing equipment operating above 425°C.

SS 321 contains titanium stabilization, which prevents carbide precipitation during welding or high-temperature service. SS 304 does not have this stabilization, making SS 321 pipes more suitable for welded high-temperature applications.

Stainless Steel 321 pipes are commonly manufactured to ASTM A312 TP321 for seamless and welded pipes, and ASTM A213 TP321 for heat exchanger and boiler tubes. Dimensional standards typically follow ASME B36.19.

Yes. SS 321 pipes offer excellent weldability without requiring post-weld heat treatment in most cases. Titanium stabilization minimizes the risk of intergranular corrosion in welded joints exposed to elevated temperatures.

Stainless Steel 321 is available in seamless, ERW, EFW, and welded pipes, as well as round, square, rectangular, and heat exchanger tubes, supplied in multiple schedules and wall thicknesses based on application requirements.

SS 321 pipes can typically operate in continuous service up to 870°C and intermittent service up to 925°C, making them suitable for high-temperature process lines, furnace components, and thermal systems.

Yes. Stainless Steel 321 pipes supplied by Aashish Metal and Alloys are delivered with Mill Test Certificates (EN 10204 3.1) and optional third-party inspection documents based on project and export requirements.

For More Information About Stainless Steel 321 Pipes & Tubes please call +91-22-66362223 / 66394926 or send an email to export@aashishmetal.com

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.